How to Wire Cannabis Oil Extraction Facilities According to NEC 2023?

Overview

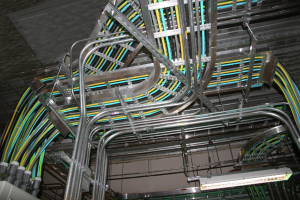

Installing wiring above hazardous locations can pose significant challenges without detailed and standardized

guidelines. As new industries emerge, it becomes essential to update these guidelines

to encompass the safety requirements of relevant facilities. To address the unique challenges of the newly legalized cannabis oil extraction industry, new safety regulations have been incorporated into the NEC 2023. Section 512.13 now specifies that wiring in these facilities, excluding oil booths, must utilize metal raceways, PVC conduits, RTRC conduits, or ENT conduits. Additionally, the use of Type MI, Type TC, or Type MC cables is mandated where necessary. These measures play a critical role in preventing hazards such as fires and explosions, thereby ensuring a safer working environment for all personnel involved.

Applying the 2023 Code

Strict safety protocols must be adhered to when installing wiring in industries that handle hazardous substances to mitigate the risk of fires and explosions. The cannabis oil extraction industry, recently legalized for mass production, has seen a rapid increase in the number of facilities, ranging from large-scale operations to smaller booth-like structures. Regardless of size, these facilities utilize highly flammable solvents such as butane, pentane, hexane, propane, and ethanol in the extraction process. Due to the volatile nature of these substances, stringent safety measures are essential to prevent accidents and ensure the well-being of personnel and facilities throughout the extraction process.

Previous editions of the NEC did not address the cannabis oil extraction industry. However, the 2023 edition introduced new regulations to promote safety within this growing sector. Section 512.13 now outlines the rules for wiring installation in cannabis oil extraction facilities, excluding oil booths. It specifies that wiring in such facilities must be conducted using metal raceways, PVC conduits, RTRC conduits, or ENT conduits. Additionally, where necessary, cables of Type MI, Type TC, or Type MC are required. By mandating specific wiring methods and cable types, the industry can significantly reduce the risk of electrical fires and explosions.

Metal raceways provide robust and protective enclosures for wires, shielding them from the volatile environment of extraction facilities. PVC conduits offer similar protection and are resistant to corrosion. RTRC and ENT conduits offer additional options, ensuring flexibility in wiring installations while upholding safety standards. Type MI, TC, and MC cables are also chosen for their durability, capable of withstanding the harsh conditions present in these facilities.

The addition of this section aims to enhance safety in all hazardous locations within the cannabis oil extraction industry, protecting both personnel and facilities.

What’s New for the 2023 NEC?

The table below presents a comparison between the 2020 NEC and the 2023 NEC regarding Section 512.13.

2020 NEC |

2023 NEC |

| In the 2020 NEC, no reference can be found for Cannabis Oil Extraction Industry. | 512.13 Wiring Installed Above Hazardous (Classified) Locations

Other than above cannabis oil booths, all fixed wiring installed at an elevation above hazardous (classified) locations [see Figure 512.3(A)(1) and Figure 512.3(A)(2)] shall be in metal raceways, PVC conduit, RTRC conduit, or ENT conduit. Where used, cables shall be Type MI, Type TC, or Type MC. |

Login with your site account

Not a member yet? Register now

Register a new account

Are you a member? Login now