How have 2023 NEC changes impacted swimming pool equipotential bonding requirements?

Overview

Equipotential bonding is a critical component of swimming pools. Without it, voltages gradients can occur over relatively

short distances and can pose a serious shock/electrocution hazard to the patrons of the swimming pool.

By bonding all critical conductive parts together, these voltage gradients are minimalized and even eliminated. This makes swimming pools much safer. The 2023 NEC has revised list item 680.26(B)(2), which covers the equipotential bonding of perimeter surfaces. These revisions contain updated distances for items requiring bonding, and contain additional provisions for different surface types, and how they are to be properly bonded.

all critical conductive parts together, these voltage gradients are minimalized and even eliminated. This makes swimming pools much safer. The 2023 NEC has revised list item 680.26(B)(2), which covers the equipotential bonding of perimeter surfaces. These revisions contain updated distances for items requiring bonding, and contain additional provisions for different surface types, and how they are to be properly bonded.

Applying the 2023 Code

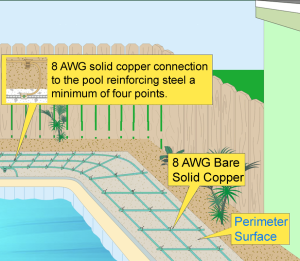

The requirements for equipotential bonding perimeter surfaces in List Item 680.26(B)(2) have been revised in the 2023 NEC. The revision now lists different perimeter surfaces, and includes specific bonding requirements for those particular surfaces. For example, 680.26(B)(2)(a) lists the requirements for conductive paved portions of perimeter surfaces. These requirements specify that conductive paving materials, such as masonry pavers, need to be bonded using a steel mesh system. Where this steel mesh system is unable to be used, an alternative option is listed. The requirements go on to require the steel grid to meet the minimum requirements of ASTM 6 × 6-W2.0 × W2.0, or No. 3 rebar in a 12″ grid. Additional requirements are listed for unpaved portions of perimeter surfaces, nonconductive perimeter surfaces, and interconnection of bonded portions of perimeter surfaces. The minimum size for bonding, when copper conductors are used, is #8 AWG.

What’s New for the 2023 NEC?

2020 NEC

In the 2020 NEC List Item 680.26(B)(2) read as follows:

(2) Perimeter Surfaces.

The perimeter surface to be bonded shall be considered to extend for 1 m (3 ft) horizontally beyond the inside walls of the pool and shall include unpaved surfaces and other types of paving. Perimeter surfaces separated from the pool by a permanent wall or building 1.5 m (5 ft) in height or more shall require equipotential bonding only on the pool side of the permanent wall or building. Bonding to perimeter surfaces shall be provided as specified in 680.26(B)(2)(a), (B)(2)(b), or (B)(2)(c) and shall be attached to the pool reinforcing steel or copper conductor grid at a minimum of four points uniformly spaced around the perimeter of the pool. For nonconductive pool shells, bonding at four points shall not be required.

(a) Structural Reinforcing Steel. Structural reinforcing steel shall be bonded in accordance with 680.26(B)(1)(a).

(b) Copper Ring. Where structural reinforcing steel is not available or is encapsulated in a nonconductive compound, a copper conductor(s) shall be utilized where the following requirements are met:

(1) At least one minimum 8 AWG bare solid copper conductor shall be provided.

(2) The conductors shall follow the contour of the perimeter surface.

(3) Only listed splicing devices or exothermic welding shall be permitted.

(4) The required conductor shall be 450 mm to 600 mm (18 in. to 24 in.) from the inside walls of the pool.

(5) The required conductor shall be secured within or under the perimeter surface 100 mm to 150 mm (4 in. to 6 in.) below the subgrade.

(c) Copper Grid. Where structural reinforcing steel is not available or is encapsulated in a nonconductive compound, copper grid shall be utilized where the following requirements are met:

(1) The copper grid shall be constructed of 8 AWG solid bare copper and be arranged in accordance with 680.26(B)(1)(b)(3).

(2) The copper grid shall follow the contour of the perimeter surface extending 1 m (3 ft) horizontally beyond the inside walls of the pool.

(3) Only listed splicing devices or exothermic welding shall be permitted.

(4) The copper grid shall be secured within or under the deck or unpaved surfaces between 100 mm to 150 mm (4 in. to 6 in.) below the subgrade.

2023 NEC

In the 2023 NEC List Item 680.26(B)(2) now reads as follows (excluding informational notes):

(2) Perimeter Surfaces.

The perimeter surface to be bonded shall be considered to extend for 900 mm (3 ft) horizontally beyond the inside walls of the pool while also at a height between 900 mm (3 ft) above and 600 mm (2 ft) below the maximum water level. The perimeter surface shall include unpaved surfaces, concrete, and other types of paving. Perimeter surfaces separated from the pool by a permanent wall or building 1.5 m (5 ft) in height or more shall require equipotential bonding only on the pool side of the permanent wall or building. Bonding to perimeter surfaces shall be provided as specified in 680.26(B)(2)(a), (B)(2)(b), (B)(2)(c), and (B)(2)(d). For conductive pool shells where bonding to perimeter surfaces is required, it shall be attached to the pool reinforcing steel or copper conductor grid at a minimum of four points uniformly spaced around the perimeter of the pool, or if the bonded perimeter surface does not surround the entire pool, it shall be attached to the pool reinforcing steel or copper conductor grid at a minimum of four uniformly spaced points along the bonded perimeter surface. For nonconductive pool shells, bonding at four points shall not be required, and the perimeter bonding shall be attached to the 8 AWG copper equipotential bonding conductor and, if present, to any conductive support structure for the pool.

(a) Conductive Paved Portions of Perimeter Surfaces. Conductive paved portions of perimeter surfaces, including masonry pavers, if used, shall be bonded with unencapsulated structural reinforcing steel in accordance with 680.26(B)(1)(a), or with unencapsulated steel structural welded wire reinforcement (welded wire mesh, welded wire fabric), bonded together by steel tie wires or the equivalent. Steel welded wire reinforcement shall be fully embedded within the pavement unless the pavement will not allow for embedding. If the reinforcing steel is absent, or is encapsulated in a nonconductive compound, or embedding is not possible, unencapsulated welded wire steel reinforcement or a copper conductor grid shall be provided and shall be secured directly under the paving, and not more than 150 mm (6 in.) below finished grade.

Unencapsulated steel welded wire reinforcement that is not fully embedded in concrete, and copper grid regardless of location, where used for equipotential bonding, shall be listed for corrosion resistance and mechanical performance. This listing requirement shall become effective January 1, 2025. The copper grid or unencapsulated steel welded wire reinforcement shall also meet the following:

(1) Copper grid is constructed of 8 AWG solid bare copper and arranged in accordance with 680.26(B)(1)(b)(3).

(2) Steel welded wire reinforcement is minimum ASTM 6 × 6-W2.0 × W2.0 or minimum No. 3 rebar constructed in a 300 mm (12 in.) grid.

(3) Copper grid and steel welded wire reinforcement follow the contour of the perimeter surface extending not less than 900 mm (3 ft) horizontally beyond the inside walls of the pool.

(4) Only listed splicing devices or exothermic welding are used.

(b) Unpaved Portions of Perimeter Surfaces. Unpaved portions of perimeter surfaces shall be bonded with any of the following methods:

(1) Copper conductor(s) shall meet the following:

(a) At least one minimum 8 AWG bare solid copper conductor, including the 8 AWG copper equipotential bonding conductor if available.

(b) The conductors follow the contour of the perimeter surface.

(c) Only listed splicing devices or exothermic welding are used.

(d) The conductor(s) is 450 mm to 600 mm (18 in. to 24 in.) from the inside walls of the pool.

(e) The conductor(s) is under the unpaved portion of the perimeter surface 100 mm to 150 mm (4 in. to 6 in.) below finished grade.

(f) Be installed only in perimeter surfaces not intended to have direct access to swimmers in the pool.

(2) Copper grid or unencapsulated steel welded wire reinforcement used for equipotential bonding of unpaved portions of perimeter surfaces shall meet the following:

(a) Be installed in accordance with 680.26(B)(2)(a).

(b) Be located within unpaved surface(s) between 100 mm to 150 mm (4 in. to 6 in.) below finished grade.

(c) Nonconductive Perimeter Surfaces. Equipotential bonding shall not be required for nonconductive portions of perimeter surfaces that are separated from earth or raised on nonconducting supports, and it shall not be required for any perimeter surface that is electrically separated from the pool structure and raised on nonconductive supports above an equipotentially bonded surface.

(d) Interconnection of Bonded Portions of Perimeter Surfaces. All surfaces where equipotential bonding is required shall be interconnected using listed splicing devices or exothermic welding. Where copper wire is used for this purpose, it shall be solid copper, not smaller than 8 AWG. The conductor shall be permitted to encircle the pool to facilitate bonding connections to portions of the perimeter covered in 680.26(B)(2)(a) and (B)(2)(b) that are not contiguous

Login with your site account

Not a member yet? Register now

Register a new account

Are you a member? Login now