Push-in vs. Twist-on: Choosing the Right Wire Connectors

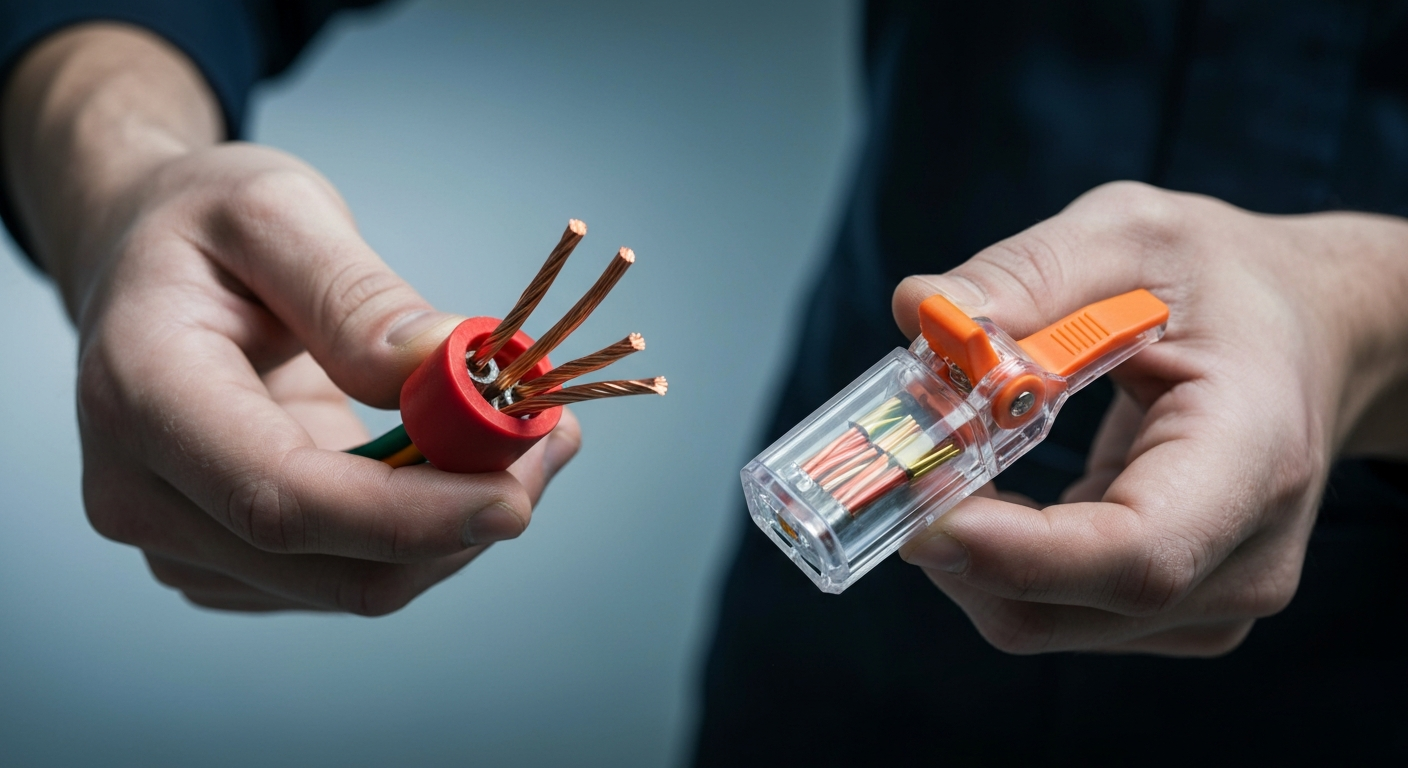

While some seasoned electricians swear by the unyielding grip of a properly twisted wire nut, others champion the undeniable speed of push-in technology, especially in large-scale projects. The global market reflects this divide, with both connector types seeing steady growth. The conversation is moving beyond simple preference to a more nuanced analysis of which connector is right for which job. It’s a discussion about code compliance, application-specific demands, and the evolving nature of the electrical trade itself.

The Old Guard: Why Wire Nuts Still Have a Place

There’s a reason twist-on connectors have been a staple for nearly a century. Their reliability is field-proven across millions of installations. For many electricians, particularly those specializing in residential rough-in work, the low cost per unit makes them the economic choice for projects involving hundreds of connections for every receptacle and set of switches. When you’re dealing with standard Romex wire, the familiar motion of stripping and twisting becomes second nature, allowing for fast and secure installations.

A properly installed wire nut creates a powerful mechanical connection. The internal spring bites into the conductors, and the twisting motion ensures the wires are bound tightly together. This method is highly effective for both solid core vs. stranded wire, provided the electrician uses the correct pre-twisting technique for stranded conductors to ensure a solid bond.

The New Contenders: The Case for Push-in and Lever-Nut Connectors

Speed is the primary driver behind the adoption of push-in connectors. Manufacturers and industry studies suggest they can reduce connection time by over 50%. In applications like commercial lighting retrofits or large-scale prefabricated assemblies, that time savings translates directly to the bottom line. Brands like Ideal In-Sure showcase the classic push-in design, while lever-style models like the WAGO 221 have become incredibly popular for their versatility.

Beyond speed, these connectors offer other key advantages:

-

- Consistency: Every connection is the same. It removes the “human factor” variability of how tightly a wire nut is twisted.

- Ease of Use: They are great for tight or awkward spaces where twisting a nut is difficult. They also reduce wrist and hand fatigue on large jobs.

– Visibility: Many push-in models feature clear housings, allowing for instant visual verification that the conductor is seated properly.

- Stranded Wire Handling: Lever-nut connectors, in particular, excel at securing stranded wire without the need for pre-twisting or worrying about stray strands.

Code, Compliance, and Connection Integrity

Ultimately, the “better” connector is the one that creates a safe, durable, and code-compliant connection. Both twist-on and push-in connectors, when purchased from reputable manufacturers, are UL listed and engineered to meet stringent safety standards like UL 486C for wire connectors.

The National Electrical Code (NEC) provides the foundational rule in NEC 110.14, which states that conductors shall be spliced with devices “identified for the use.” This means as long as the connector is used according to its listing and manufacturer’s instructions, it’s a compliant choice. Staying on top of code is crucial, which is why understanding how 2023 NEC terminal connection requirements are different is essential for every professional.

Several technical factors come into play when evaluating connector integrity:

- Conductor Strip Length: This is arguably the most critical factor for push-in success. An improper strip length—too short or too long—is a primary cause of failure. Always use the strip gauge on the side of the connector.

- Terminal Retention Strength: This is the pull-out force a conductor can withstand. While a perfectly installed wire nut has immense retention strength, quality push-ins are tested to hold tight under normal conditions.

- Thermal Cycling Failure: As connections heat and cool under load, materials expand and contract. Both connector types are designed to mitigate this, but poor connections of any type can loosen over time.

- Vibration Resistance: For installations near motors, generators, or heavy equipment, vibration resistance is a major concern. In these scenarios, lever-nut connectors or traditional screw terminals may offer a more secure connection than either a basic push-in or a wire nut.

Choosing the Right Connector for the Application

A master electrician knows the choice isn’t about brand loyalty; it’s about matching the tool to the task. The context of the installation for devices like receptacles and switches is key. For a deeper dive, it’s worth reviewing how 2023 NEC changes affect receptacle termination types and the specific rules on snap switch terminations.

Consider these scenarios:

- Residential Rough-in: With hundreds of standard splices using solid copper, the cost-effectiveness and proven track record of wire nuts make them a top choice.

- Commercial Lighting Retrofit: When replacing thousands of fixtures, often on a lift and in awkward positions, the speed and one-handed operation of push-in wire connectors can dramatically reduce labor costs.

- Crowded Junction Box: The predictable, compact shape of push-in connectors can be a significant advantage when dealing with tight junction box fill calculations.

- High-Amperage Connections: For circuits approaching the upper limits of the wire gauge, many electricians prefer the robust security of screw-down terminals or specialized connectors designed specifically for high-amperage connections.

The Verdict: The Best Electricians Have a Diverse Toolbox

The push-in vs. twist-on debate is not about finding a single winner. It’s about recognizing that our trade is evolving. A skilled electrician understands the strengths and weaknesses of every tool and material available. While wire nuts remain a cost-effective and reliable standard for many common jobs, ignoring the efficiency gains and specific advantages of push-in and lever-nut connectors means leaving money and time on the table.

The modern, professional approach is to stock your truck with both. Use the connector that best fits the wire type, the application, the environment, and the economics of the job. By prioritizing code compliance and proper installation technique above all else, you ensure every connection you make is safe, secure, and built to last.

Staying current on the latest materials and code changes is what separates the best from the rest. To keep your knowledge sharp and your skills competitive, browse our courses and invest in your professional development.

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)