How to Size Wire for a 30 Amp Dryer Circuit (NEC Guide)

How to Size Wire for a 30 Amp Dryer Circuit (NEC Guide)

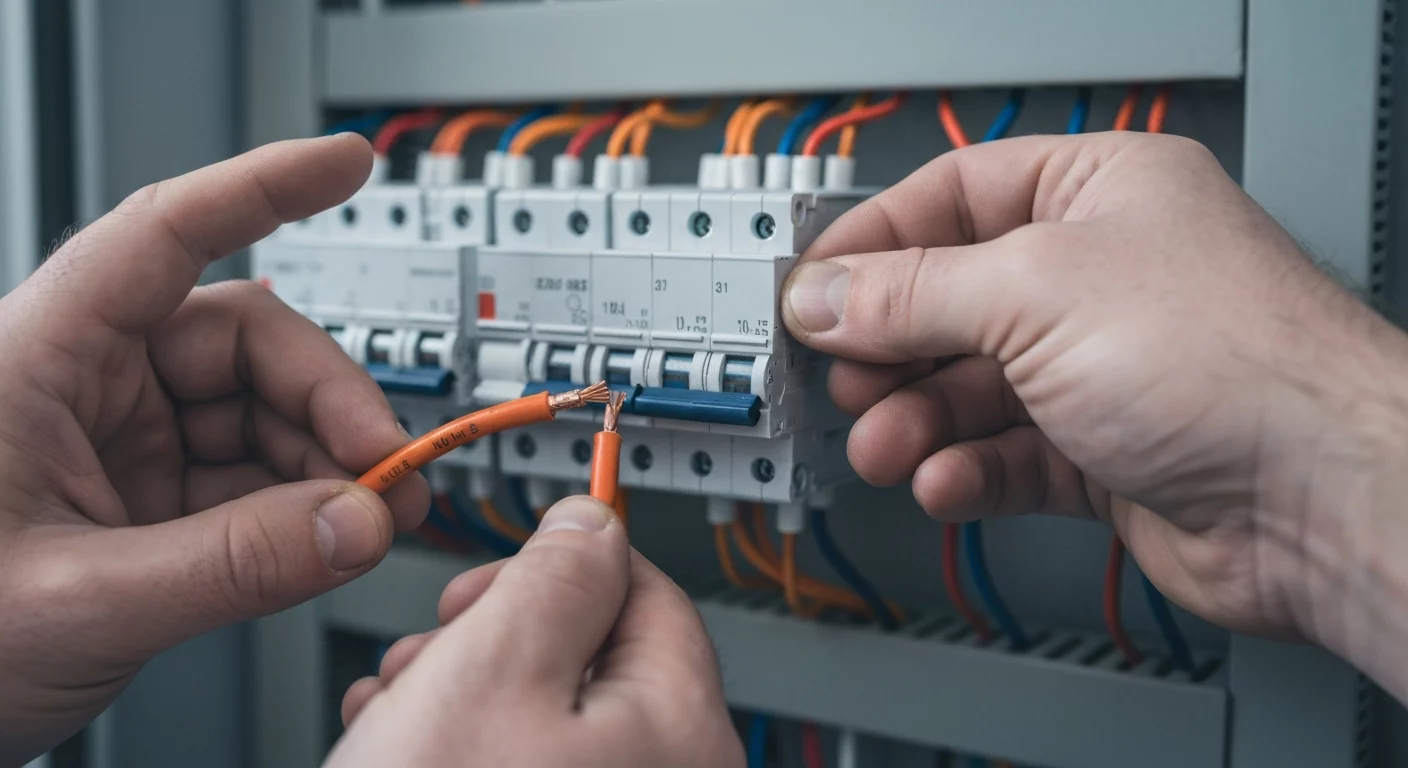

For a standard 240-volt, 30-amp electric dryer circuit, the correct 30 amp wire size is a 10 AWG copper conductor. This wire must be part of a 4-wire circuit, which includes two hot wires, one neutral, and one equipment ground. This setup connects to a 30 amp breaker—specifically a double-pole circuit breaker—in the electrical panel and terminates at a modern NEMA 14-30 receptacle. According to the National Electrical Code (NEC), this configuration ensures proper overcurrent protection and safety. While 10 AWG copper is the baseline, factors such as a long wire run may require a larger wire (like 8 AWG copper) to compensate for voltage drop. The ampacity for this wire size is confirmed in NEC Table 310.16. A licensed journeyman electrician will always verify these specifications to ensure a compliant and safe installation for this dedicated circuit.

NEC Code Requirements for Dryer Circuit Wiring

Properly wiring a 240-volt dedicated circuit for an electric dryer is a fundamental task for any electrician, governed by strict safety standards outlined in the nec code book. The foundation of a safe installation is correct branch circuit sizing, which involves matching the wire, breaker, and receptacle to the appliance’s load.

Understanding NEC Table 310.16 for Conductor Ampacity

The starting point for determining the correct wire size is the conductor ampacity, which is the maximum current a conductor can handle continuously without exceeding its temperature rating. For this, electricians turn to NEC Table 310.16 (formerly known as NEC Table 310.15(B)(16) in older code editions). This essential wire ampacity chart provides the allowable ampacities for insulated conductors.

According to this table, a 10 AWG copper conductor has an ampacity of 30 amps at 60°C and 35 amps at 75°C; however the ampacity you use must not exceed the lowest temperature rating of any connected termination (often 60°C). This makes 10 AWG the standard choice for a 30-amp dryer circuit when 60°C terminations apply. It’s critical to consider the terminal temperature rating of the breaker and receptacle, which is typically 60°C or 75°C. The ampacity used must not exceed the lowest temperature rating of any connected component in the circuit.

Overcurrent Protection: Sizing the 30 Amp Breaker

The wire is only one part of the equation; it must be protected by an appropriately sized overcurrent protection device. For a dryer circuit, this is a 30 amp breaker. Because the circuit provides 240 volts, it requires a double-pole circuit breaker that connects to two different bus bars in the panel, providing two hot conductors. This breaker ensures that if the current exceeds 30 amps, the circuit will be safely disconnected. Sizing the breaker and conductor together is a core principle of overcurrent protection. For a deeper dive into this topic, you can review our guide on how to properly size a circuit breaker based on NEC rules.

Key Factors Influencing Wire Size Selection

While 10 AWG copper is the standard answer, a professional electrician knows that site-specific conditions can demand adjustments. Failing to account for these variables can lead to poor performance and safety hazards.

Voltage Drop Calculation for Long Circuits

Voltage drop is the reduction of electrical potential along the path of a current. For long wire runs (typically over 100 feet), this drop can become significant enough to affect the dryer’s performance and lifespan. The NEC (informational material and common industry practice) recommends keeping voltage drop to a maximum of about 3% on branch circuits for acceptable performance; this is guidance rather than a mandatory sizing rule. If a voltage drop calculation shows a drop exceeding this threshold, you must use a larger wire. For a 30-amp circuit, this often means upsizing to an 8 AWG copper conductor. Many professionals use a size electrical wire calculator or a dedicated voltage drop calculator to quickly verify if an upgrade is needed for a specific distance.

Ambient Temperature Correction

Conductor ampacity is rated for a specific ambient temperature (usually 30°C or 86°F). If the wire is run through an unusually hot environment, such as an attic in a hot climate, its effective ampacity is reduced. The NEC provides ambient temperature correction factors in the ampacity adjustment tables to account for this. If the corrected ampacity of a 10 AWG wire falls below 30 amps, a larger gauge wire is required.

Conduit Fill Derating

When multiple current-carrying conductors are bundled together in a conduit, they generate heat that cannot dissipate as efficiently. The NEC requires conduit fill derating (adjustment) if you have more than three current-carrying conductors in a single raceway. For a typical dryer circuit, this is not an issue, but in complex installations where wires are run together, these adjustments are mandatory and may force you to use a larger conductor to maintain a 30-amp capacity.

Choosing the Right Components for a 4-Wire Circuit

Modern electrical codes mandate a 4-wire circuit for new dryer installations, a significant safety improvement over older 3-wire systems. This includes two hot conductors, a neutral, and a separate equipment grounding conductor.

The Modern Standard: NEMA 14-30 Receptacle

The proper dryer outlet for a new installation is a NEMA 14-30 receptacle. This 4-slot outlet is designed to accept a 4-prong dryer cord, ensuring a dedicated path for grounding that protects against electric shock. The transition from older 3-prong (NEMA 10-30) outlets is a major safety upgrade, as the older standard used the neutral wire as a ground, a practice not permitted for new installations under the nec code book. Understanding these grounding rules is critical, as detailed in our guide to simplified grounding rules for ranges and dryers in NEC 2023.

Romex Wire (NM-B) vs. Individual Conductors

For most residential applications, electricians use Type NM-B cable, commonly known by the brand name Romex wire. For a dryer circuit, you would use “10/3 with ground” NM-B cable. This sheathed cable contains two hot conductors and a neutral (black, red, white) plus a bare copper grounding conductor. In situations where wiring is run through conduit (e.g., in a basement or garage), an electrician might pull individual THHN/THWN conductors instead.

Copper vs. Aluminum: Sizing the Aluminum Wire Equivalent

While copper is more common, aluminum wire can also be used. However, aluminum is less conductive than copper, so you must use a larger wire to achieve the same ampacity. The exact size must be confirmed from the NEC ampacity tables and the equipment’s connection ratings, but in many practical installations installers select a larger aluminum conductor (commonly 8 AWG aluminum for this service) and use the appropriate aluminum-rated lugs and anti-oxidant compound. It is crucial to use anti-oxidant compound on aluminum connections and ensure the breaker and receptacle are rated for aluminum wire (marked AL/CU).

Step-by-Step Guide to Branch Circuit Sizing for a Dryer

Follow these steps to ensure a compliant and safe dryer circuit installation:

- Verify Appliance Load: Confirm the dryer requires a 30-amp, 240-volt circuit. This information is found on the appliance’s nameplate. While most standard electric dryers use this, it’s a critical first step. Note that a dryer is not considered a continuous load in residential settings per NEC definitions.

- Select Overcurrent Protection: Choose a double-pole 30 amp circuit breaker and install it in the panel. For more details on this step, you can learn how to wire a dryer receptacle correctly.

- Determine Conductor Type and Size: Based on NEC Table 310.16, select a 10 AWG copper conductor or a larger aluminum conductor verified from the NEC ampacity tables. The most common choice for residential installations is a 10/3 NM-B cable.

- Account for Derating Factors: Evaluate the wire run length and ambient temperature. Use a voltage drop calculator if the run exceeds 100 feet. If necessary, upsize the conductor to 8 AWG copper to mitigate voltage drop. Apply temperature correction if the wire passes through hot areas.

- Install the Circuit: Run the cable from the panel to the outlet location, following all local code requirements for securing and protecting the cable.

- Terminate at the Receptacle: Install a NEMA 14-30 receptacle. Connect the black and red wires to the hot terminals (brass screws), the white wire to the neutral terminal (silver screw), and the bare copper wire to the ground terminal (green screw).

By mastering these code requirements and practical considerations, you can confidently wire any appliance. Enroll in our residential wiring courses to further your expertise.

Related Resources

Frequently Asked Questions (FAQ)

What size breaker do I need for a 10 gauge wire?

For a standard copper 10 gauge wire (10 AWG), you should use a 30-amp breaker. This pairing is the standard for applications like electric dryers, as the conductor ampacity of 10 AWG copper is 30 amps at 60°C per the NEC ampacity tables, and terminations often govern the temperature rating used for the final selection.

Can I use 8 gauge wire for a 30 amp dryer?

Yes, you can use 8 AWG wire for a 30-amp dryer. While 10 AWG is the minimum 30 amp wire size required for copper in typical terminations, using a larger wire like 8 AWG is a good practice for very long runs to prevent voltage drop. It is also the practical choice when aluminum conductors are required, after verifying ampacity from the tables and equipment ratings.

What happens if you use 12 gauge wire on a 30 amp breaker?

Using 12 gauge wire on a 30-amp breaker is a serious fire hazard and a major code violation. A 12 AWG copper wire is only rated for 20 amps at typical termination ratings. A 30 amp breaker will allow up to 30 amps of current to flow through the wire, causing it to overheat, melt its insulation, and potentially start a fire long before the breaker trips.

What is the difference between a NEMA 14-30 and 10-30 dryer outlet?

The main difference is safety and the number of wires. A NEMA 14-30 is a modern 4-prong dryer outlet that uses a 4-wire circuit with a dedicated ground wire. A NEMA 10-30 is an older 3-prong outlet that used the neutral wire as a ground, which is no longer permitted for new installations under the nec code book.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)