A Helper’s Guide to Electrical Fasteners: Wire Nuts to Cable Ties

A Helper’s Guide to Electrical Fasteners: Wire Nuts to Cable Ties

In the world of electrical work, the quality of your connections is paramount. From a simple light fixture installation to wiring a complex panel, the small components that join and secure conductors—electrical fasteners—are the unsung heroes of a safe and reliable system. A deep understanding of the different types of wire nuts, connectors, and securing methods is non-negotiable for any professional. This guide covers the essential fasteners, from traditional twist-on wire connectors and modern push-in wire connectors to the best methods for tying cables, ensuring every electrical wire splicing job complies with National Electrical Code (NEC) standards. Whether you’re working inside an electrical junction box or managing runs of Romex, choosing the correct fastener, from wire nuts to tie wrap cable ties, is a mark of true craftsmanship and a critical safety measure.

Understanding the Core of Electrical Wire Splicing: Wire Connectors

At its heart, electrical work is about creating controlled paths for electricity. Where conductors join, a secure and insulated connection is critical. This is where wire connectors come in, providing a safe method for electrical wire splicing inside a protected enclosure like an electrical junction box. For decades, the debate in the field has centered on two main categories: traditional twist-on wire nuts and modern push-in or lever-style connectors. While many seasoned electricians trust the proven reliability and low cost of twist-on wire connectors, listed push-in and lever-style connectors are increasingly used for certain applications because they can offer labor savings. Always install the specific connector exactly per the manufacturer’s listing and instructions. You can learn more about this industry debate in our comprehensive guide to wire connectors.

The Definitive Guide to Types of Wire Nuts

When electricians refer to “wire nuts,” they are typically talking about twist-on wire connectors. These iconic, cone-shaped devices feature a plastic insulating shell and an internal metal spring that bites into the conductors, creating a secure mechanical and electrical bond. However, the world of wire connectors is diverse, with specialized options for various applications.

- Twist-on Wire Connectors: The industry standard for many residential and commercial wiring tasks. Their effectiveness relies on proper installation, including stripping wires to the correct length and tightening the connector until it is secure per the manufacturer’s instructions.

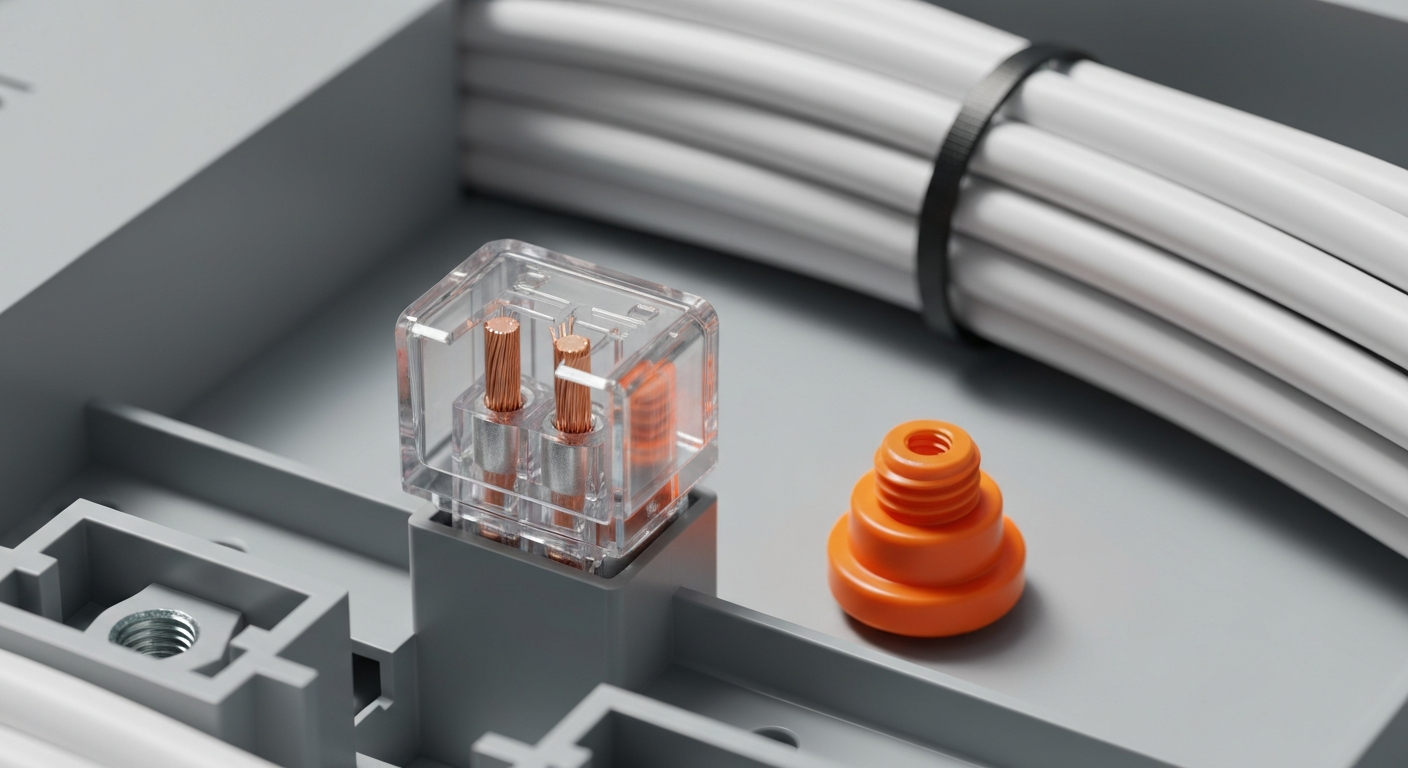

- Push-in Wire Connectors: Modern alternatives that allow electricians to insert stripped conductors into individual ports. Some have transparent housings for visual confirmation and can speed repetitive splices when they are listed for the intended conductor types and combinations.

- High-Temperature Wire Nuts: Specialty connectors listed for high-temperature applications are used where standard plastic housings would not withstand the temperature — for example, in certain heating appliances or other elevated-temperature locations. Use only connectors listed for the specific temperature environment.

- Waterproof/Direct-Burial Connectors: For outdoor, direct-burial, or consistently damp applications (like landscape lighting), only use connectors listed for that use. Listed direct-burial or weatherproof connectors include sealing compounds or designs intended to resist moisture and corrosion.

- Connectors for Aluminum-to-Copper Joints: Aluminum-to-copper connections require connectors listed for AL/CU service; manufacturers sometimes color-code these (one common example is purple for some brands), but colors are not universal — always verify the connector is specifically listed for joining aluminum and copper and follow any antioxidant or installation instructions. Such connections should be made with devices listed for the purpose and installed per the device listing (see NEC guidance on terminations and listed devices).

- Grounding Connectors: Connectors intended for equipment grounding conductors are provided in forms listed for that application. Some are color-coded green or otherwise identified for grounding, but the authoritative requirement is that the connector is listed for grounding use and installed per its listing.

Decoding Wire Nut Color Codes

The color of a connector is a manufacturer aid to identify capacity quickly, but color conventions vary across brands. There is no single universal color standard that applies to every manufacturer. Always verify the connector’s allowed wire-gauge ranges, combinations, and listing on the packaging or product documentation before use. Examples from common practice vary by brand and are not a substitute for the manufacturer’s instructions.

How to Correctly Install a Twist-On Wire Connector

A faulty connection is a future failure point. Following a precise process ensures every splice is secure and safe, providing proper electrical insulation.

- Safety First: Always de-energize the circuit and verify it is off with a multimeter or non-contact voltage tester.

- Prepare the Conductors: Strip an appropriate length of insulation per the connector manufacturer’s instructions (commonly around 1/2 to 3/4 inch on many residential connectors). Ensure the stripped lengths are uniform.

- Align and Hold: Hold the stripped ends of the wires together so the insulation is aligned. For many solid conductors, pre-twisting is not required when using listed twist-on connectors; follow the connector listing.

- Secure the Connector: Place the connector over the conductor ends and turn it clockwise, pushing until it is mechanically secure per the manufacturer’s instructions. It should feel tight and not loose on the conductors.

- Perform the Tug Test: Gently tug on each individual wire to ensure it is firmly gripped by the connector and will not pull out. Visually inspect the connection to ensure no bare conductor is exposed below the connector skirt unless the connector is listed to allow a certain conductor protrusion.

Beyond Splicing: Cable Management and Securing

Properly fastening wires is only half the battle; securing and managing them is just as important for safety and a professional-looking installation. A tidy installation is easier to troubleshoot and maintain. For a deeper dive, check out our electrical cable management guide.

Tying Cables Effectively: The Role of Tie Wrap Cable Ties

For effective cable bundling, tie wrap cable ties (or zip ties) are indispensable. They are used to group low-voltage cables, organize conductors within a panel, or provide support for communication lines. When tying cables, avoid cinching ties so tightly that they deform or damage the cable insulation, which can impair performance, especially with data cables. Releasable or hook-and-loop style ties are excellent alternatives in areas where cables may be added or changed in the future. For more on this, see our guide on how electrical cables should be tied.

Securing Romex and Other Cables

Nonmetallic-sheathed cable (Romex) must be secured and supported per NEC requirements (see NEC Article 334). This is typically done with staples or specialized straps. Use the appropriate cable staple or strap and avoid overdriving staples, which can pinch or damage the cable jacket. At entry points into a junction box, panel, or conduit, provide a listed cable connector or clamp where required to protect the cable from the box knockout edges and to provide strain relief; the exact requirement depends on the box and installation (see NEC guidance on cable entries and clamps).

The Versatility of Electrical Tape

While electrical tape can provide temporary or supplemental insulation, it must not be used as a substitute for a listed connector. Splices and terminations are required to be made with devices listed for the purpose (per NEC). Where additional protection or abrasion resistance is desired over a properly made, listed connection, appropriate tapes or listed weatherproofing methods may be used as supplemental protection, again following the device and material listings.

Other Essential Electrical Fasteners

A professional’s tool bag contains more than just wire nuts. Other fasteners are critical for a complete installation.

- Terminal Lugs: Used to terminate larger gauge conductors onto screw terminals or bus bars. The wire is inserted into the lug barrel and crimped or mechanically attached as specified by the lug listing and manufacturer instructions.

- Self-Tapping Screws: Useful for mounting boxes, panels, and equipment to metal studs or enclosures without pre-drilling, when permitted by the equipment instructions and local rules.

Key Considerations and NEC Standards

Using these fasteners correctly is a matter of safety and code compliance. Always keep these points in mind:

- Always adhere to National Electrical Code (NEC) standards for all splices and connections, particularly Article 110.14 on terminations and connection methods, Article 300.15 on boxes and fittings where splices and terminations occur, and Article 334.30 for securing nonmetallic-sheathed cable (Romex).

- Verify wire gauge compatibility on the manufacturer’s packaging for any connector you use. Using a connector that is too large or too small for the intended conductors can result in a poor or unsafe connection.

- Only use fasteners and connectors that are “listed” and “labeled” by a recognized testing laboratory (such as UL) for their intended purpose (for example, direct-burial rated, high-temperature rated, or listed for grounding).

- Do not reuse a connector unless the manufacturer explicitly allows reuse — many connectors are intended to be installed once in accordance with their listing.

- Proper electrical insulation is the goal. After a splice is made with a listed connector or device, no conductive parts that could be contacted should be exposed.

Properly using these fasteners is a core skill that separates amateurs from professionals. To deepen your understanding and stay current with code, explore our courses on proper wiring and termination techniques.

Frequently Asked Questions (FAQ)

What do the different wire nut color codes mean?

Wire nut color codes are manufacturer aids indicating a connector’s permitted wire-gauge ranges and conductor combinations for that product. Because colors are not universally standardized across all manufacturers, always check the connector’s packaging and listing for exact wire gauge compatibility.

Can you use electrical tape instead of wire nuts for electrical wire splicing?

No. Electrical tape is not an acceptable substitute for listed connectors such as twist-on wire connectors or other listed splice devices for permanent electrical wire splicing. NEC requires listed devices for splices and terminations; tape is only for supplemental insulation if used over an appropriate listed connection.

What are the best methods for tying cables and cable bundling?

The best method for tying cables depends on the application. For permanent cable bundling of low-voltage or data cables, tie wrap cable ties are efficient but should not be over-tightened. For areas requiring future changes, reusable hook-and-loop (Velcro) straps are recommended because they are adjustable and prevent cable damage.

When should I use push-in wire connectors versus traditional twist-on wire connectors?

The choice comes down to the connector’s listing, the application, and installer preference. Push-in connectors can speed repetitive splices and offer visual confirmation on some models, but they must be listed for the conductor types and combinations in use. Traditional wire nuts remain a cost-effective, reliable solution when installed correctly and per listing.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)