Romex vs. MC Cable vs. THHN: A Helper’s Identification Guide

Romex vs MC Cable vs THHN: An Electrician’s Identification Guide

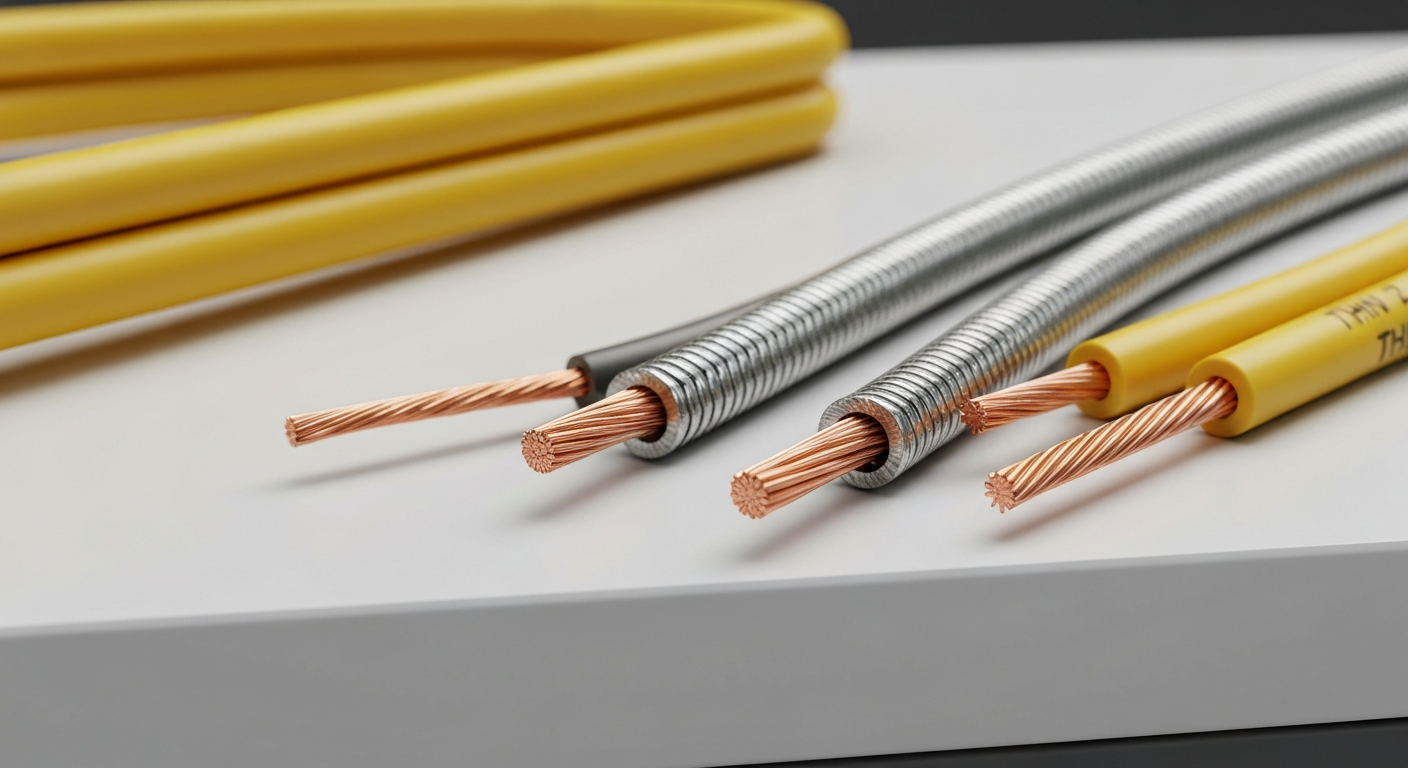

In the world of electrical wiring, choosing the correct cable is critical for safety, code compliance, and efficiency. For any residential or commercial electrician, the debate of romex vs mc cable is a daily consideration, with THHN wire serving a different but equally vital role. Romex, technically Non-metallic sheathed cable (NM-B), is the go-to for many residential wiring applications due to its cost-effectiveness and ease of installation in protected, dry locations. In contrast, MC cable, or metal-clad cable, is a listed metal-clad factory assembly that provides built-in metallic protection and is commonly used for exposed runs and many commercial applications. Meanwhile, THHN conductors are individual insulated wires that are intended for installation in approved wiring methods (for example, raceways) and are widely used when a conduit-based approach is required. Understanding the distinct construction, applications, and National Electrical Code (NEC) rules for each is fundamental to any professional electrician training program.

For a broader overview of different wiring options, ExpertCE offers a comprehensive electrical cable types guide to expand your knowledge base.

What is Romex® (Non-metallic Sheathed Cable)?

Romex® is a brand name for Type NM-B cable, a type of Non-metallic sheathed cable that is ubiquitous in modern residential wiring. As defined in NEC Article 334, it consists of two or more insulated conductors bundled together and enclosed within a nonmetallic sheath (a thermoplastic outer covering). A typical NM-B assembly, such as a 12/2 cable, contains two insulated conductors and an equipment grounding conductor; the conductors and the cable sheath must meet the construction and marking requirements specified in Article 334.

The primary advantage of romex wire is its material and installation efficiency in standard wood-frame construction. However, the NEC restricts NM cable to specified permitted uses and locations; in particular, NM is intended for normally dry locations and has defined limits on where it may not be used (see Article 334 for permitted and not-permitted locations). For a deeper dive into its specific uses and limitations, you can explore this guide to NM cable types.

What is MC Cable (Metal-Clad Cable)?

MC cable, which stands for metal-clad cable, is a factory-assembled cable assembly governed by NEC Article 330. It consists of insulated conductors enclosed by a metallic covering. MC is a listed cable assembly and, depending on its listed construction, can provide an effective equipment grounding path as part of the assembly. The NEC describes the permitted uses for Type MC cable and the conditions under which certain MC constructions may be used in damp or corrosive locations; consult Article 330 for details.

Modern MC cable differs from older armored-cable types, and MC constructions commonly provide an equipment grounding conductor or are listed as providing an effective equipment grounding path. For grounding and equipment-grounding path requirements related to cable types, see Article 250 and Article 330; additionally, Article 250.118 specifically lists MC cable among wiring methods that can provide an equipment grounding conductor or grounding path when constructed and listed for that purpose.

Primarily used in commercial applications, MC cable is also used in residential settings where exposed runs or additional mechanical protection is desired, such as basements or garages. Its durability and listed characteristics make it a suitable choice where the wiring is subject to mechanical impact or where listing for a particular environment is required.

What is THHN Wire?

Unlike Romex and MC cable, which are cable assemblies, THHN wire is a type of single insulated conductor. The term indicates a thermoplastic-insulated conductor with a nylon jacket (THHN). These conductors have thermoplastic insulation and a nylon overjacket, providing resistance to heat and abrasion appropriate for the conductor type per NEC tables. Many modern thermoplastic conductors are dual-rated (for example THHN/THWN) so they can be used in more than one environment, depending on their listing and application.

NEC tables list THHN and dual-rated conductor types along with their location and temperature ratings; for example, THHN is associated with a 90°C maximum operating temperature in dry locations per the NEC tables and dual ratings such as THHN/THWN indicate listing for additional conditions. Because THHN conductors are single conductors, NEC requirements specify the permitted wiring methods for installing single conductors, and they are commonly installed inside raceways such as EMT, rigid conduit, or other allowed methods. Consult Article 310 and the applicable raceway articles for installation requirements when using single conductors.

Core Differences: Romex vs MC Cable vs THHN

Choosing between these three wiring methods depends on environment, code requirements, and the specific installation. Each has distinct advantages and limitations that every electrician must know to achieve a safe, code-compliant installation.

Construction and Physical Protection

- Romex (NM-B): Features a nonmetallic thermoplastic sheath that provides limited mechanical protection; NM wiring is intended for installation in protected locations in accord with Article 334 and must be protected where subject to physical damage.

- MC Cable: Is a metallic-covered, listed cable assembly that provides mechanical protection as part of its construction and can serve as an equipment grounding path when listed to do so; consult Article 330 and Article 250.118 for details on permitted applications and grounding considerations.

- THHN Wire: Is an individual insulated conductor (thermoplastic with nylon jacket) and does not provide mechanical protection on its own; it must be installed in an approved wiring method (for example a listed raceway) as shown in the NEC tables and the applicable raceway articles.

Common Applications: Residential vs. Commercial

- Romex (NM-B): The dominant choice for many residential wiring applications inside walls, ceilings, and floors in normally dry conditions; NM is limited to the permitted uses in Article 334.

- MC Cable: Common in commercial applications and for exposed runs where a listed metallic-clad assembly and its mechanical protection are appropriate; also used where the listing or environment requires the attributes MC provides.

- THHN Conductors (in Conduit): Used where a conduit or raceway method is required or advantageous—typical in commercial, industrial, underground, or other installations where conduit-based wiring is specified. Consult the raceway articles and Chapter 9 for conductor sizing and conduit fill.

Installation and NEC Considerations

The NEC contains specific installation rules for each wiring method. NM cable support and securing are addressed in Article 334 (for example, support intervals not exceeding 1.4 m (4 1/2 ft) and securing within 300 mm (12 in.) of cable entries), and Type MC cable support and securing requirements are in Article 330 (for example, general securing/support intervals not exceeding 1.8 m (6 ft) unless permitted otherwise). Single conductors such as THHN must be installed in wiring methods that the NEC allows for single conductors (see Article 310 and the conduit and raceway articles for details). Always consult the specific NEC articles that govern each wiring method for the exact rules that apply.

For additional perspectives on NM/NMC rule updates and practical implications for installation, you may also find how the 2023 NEC updates have changed NM and NMC cable installation rules helpful.

Cost and Labor

On a material basis, NM cable is commonly less expensive than MC cable. The total installed cost depends on labor, protection requirements, permitted wiring methods, and accessibility. While NM is quick to staple in open wood framing, MC or conduit with THHN may be preferable where raceways, durability, or future flexibility (pulling conductors) are priorities. Balance material cost, labor, and long-term durability when choosing a method.

Step-by-Step: Calculating Conduit Fill for THHN Conductors

A critical skill in any electrician training is correctly calculating conduit fill to comply with the NEC. Overfilling a conduit can lead to excessive heat and damage to wires. Use NEC Chapter 9 tables for the exact values; the general method is:

- Identify Conductors and Conduit: Determine the sizes and insulation types of the THHN conductors to be used and the raceway type and size.

- Find Conductor Area: Look up the conductor cross-sectional area in the Chapter 9 conductor area table for the conductor/insulation type you will use.

- Calculate Total Conductor Area: Multiply the area of one conductor by the total number of conductors to be installed in the raceway.

- Determine Allowable Fill Percentage: Use the NEC Chapter 9 guidance for the applicable fill percentage (for example, different percentages apply for one, two, or more conductors).

- Find Conduit Area: Look up the internal cross-sectional area for your conduit size in Chapter 9 tables.

- Calculate Allowable Fill Area: Multiply the conduit internal area by the allowable fill percentage to get the maximum allowable conductor area for that conduit.

- Verify Compliance: Compare your total conductor area to the allowable fill area. If the total conductor area is less than or equal to the allowable fill area, the installation meets the Chapter 9 conduit fill requirements.

For the exact numeric values, consult NEC Chapter 9 tables and your jurisdiction’s referencing of those tables. The NEC and Article 310 provide the required Chapter 9 references for conductor area and conduit tables.

Key Takeaways for the Professional Electrician

- Romex (NM-B): Appropriate for many standard, protected residential wiring applications; check the permitted uses in Article 334.

- MC Cable: Often the preferred listed metal-clad assembly for exposed indoor runs and many commercial applications where a listed metallic-clad cable and its listed grounding characteristics are appropriate (see Article 330 and Article 250.118).

- THHN Conductors: Used within raceways or other approved wiring methods when single-conductor installations are required; refer to the applicable raceway articles and Chapter 9 for conduit fill and related requirements.

- Code is Key: Always refer to the latest edition of the NEC code book (NFPA 70) and local amendments. Rules for support, protection, ampacity ratings (see Article 310), and permitted uses are mandatory for a safe and compliant electrical inspection.

- Consider the Entire Job: Evaluate material cost, labor, inspection/approval criteria, and long-term durability. The cheapest material might not produce the lowest overall project cost when protection and code compliance are considered.

Primary Sources

- NFPA 70, National Electrical Code (NEC), 2023 Edition

Frequently Asked Questions

- What is the main difference in Romex vs MC Cable for a residential electrician?

- For a residential electrician, the main practical difference is the construction and permitted use: NM cable is intended for installation in normally dry, protected spaces within walls, floors, and ceilings per Article 334, while MC cable is a listed metal-clad assembly commonly used where the metallic covering and listing are appropriate for exposed runs or where mechanical protection or listing is required.

- Can you use THHN wire outside of conduit?

- No. THHN wire is a single insulated conductor and must be installed in wiring methods that the NEC permits for single conductors (for example, pulled in raceways). See Article 310 and the raceway articles for permitted methods.

- Is MC cable the same as BX cable?

- No. Modern Type MC cable is a listed metal-clad cable assembly governed by Article 330 and is commonly constructed and listed for an effective equipment-grounding path. Older armored cable types (often called AC or BX) differ in construction and historical application; consult the NEC and product listings for the specific distinctions and permitted uses.

- When does the NEC code book require metal-clad cable instead of Romex?

- The NEC requires a wiring method with appropriate physical protection where NM cable would be subject to physical damage or where NM is not a permitted wiring method. Article 334 (NM) and Article 330 (MC) define where each method is permitted; use the NEC articles to determine the correct wiring method for the location.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)