Healthcare Spaces: Equipment Grounding Clarified in NEC 2023

NEC 2023 Grounding and Bonding: Your Answer-First Summary

The 2023 National Electrical Code (NEC) reinforces and clarifies critical equipment grounding requirements for healthcare facilities, primarily within Article 517. For electricians, a key requirement is redundancy for grounding of branch circuits in patient care vicinities. NEC 517.13 requires both an effective equipment grounding path provided by a metallic raceway or metallic cable armor (which qualifies as an equipment grounding conductor under NEC 250.118) and an insulated equipment grounding conductor installed with the branch-circuit conductors. In other words, patient care branch circuits are expected to provide both a metallic-path grounding means and an insulated EGC unless a specific exception applies.

The Critical Role of Grounding and Bonding in Healthcare Facilities

In most commercial or residential settings, the primary goal of the equipment grounding conductor (EGC) is to provide a low-impedance path for fault current to facilitate the operation of an overcurrent protective device. While this is still true in healthcare, Article 517 emphasizes an even more sensitive objective: patient safety. Patients, especially those with compromised health or connected to medical equipment, are highly susceptible to microshock—a potentially lethal effect caused by extremely small currents passing directly through the heart.

Effective NEC 2023 grounding and bonding practices within the Patient Care Vicinity are a primary line of defense against these hazards. The goal is touch voltage mitigation. By ensuring conductive surfaces a patient or caregiver might touch are at similar electrical potential, we reduce the risk that a dangerous current will flow through a patient’s body.

NEC 2023 Article 517: Key Grounding and Bonding Updates

While the 2023 NEC didn’t change the fundamentals, it clarified requirements and reinforced established principles.

Redundant Grounding: The ‘Belt and Suspenders’ Approach in NEC 517.13

Section 517.13, “Grounding and Bonding of Receptacles in Patient Care Spaces,” is a fundamental reference for electricians working in hospitals. It requires that branch circuits serving patient care spaces provide an effective ground-fault current path by being installed in a metallic raceway or by using a cable with metallic armor or sheath that qualifies under NEC 250.118. It also requires an insulated equipment grounding conductor to be installed with the branch-circuit conductors.

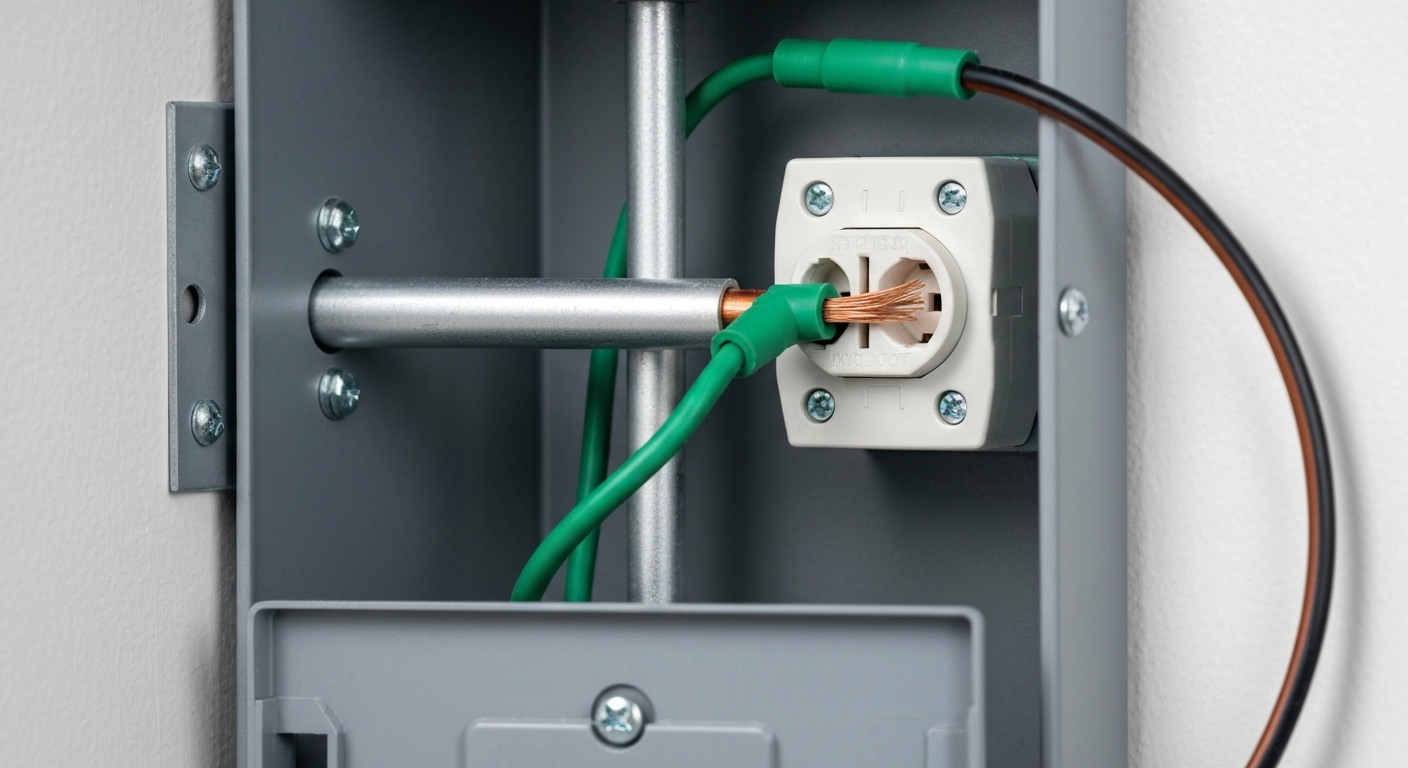

In practice, that means both of the following are provided for these branch circuits:

- Path 1: A properly installed metallic raceway or metallic cable armor that functions as an equipment grounding conductor.

- Path 2: An insulated equipment grounding conductor installed with the branch-circuit conductors and identified along its entire length by green insulation.

This dual-path approach ensures that if one path is compromised (for example, by a damaged fitting or a separate fault) a reliable, low-impedance ground path remains. Note there are limited exceptions in the Code for specific situations; always check Article 517 and related exceptions during design and installation.

Establishing an Equipotential Approach in Patient Care Vicinities

In Category 1 (critical care) spaces, the NEC provides measures for implementing an equipotential approach to keep conductive surfaces in the patient’s immediate environment at similar potential. This is typically implemented by bonding conductive surfaces in the patient care vicinity to a reference grounding point or patient equipment grounding point (when used). Typical items included for bonding are exposed structural metal, equipment grounding terminals of receptacles, and other conductive surfaces likely to become energized. Those bonding points are connected to the grounding system associated with the patient-care electrical distribution (in practice this ties back to the panelboard grounding/bonding system). When applied, these bonding measures reduce voltage gradients in the patient care vicinity and help protect vulnerable patients.

Step-by-Step: Verifying a Compliant Redundant Grounding System

Proper installation is critical. A visual inspection and systematic verification process are necessary to ensure compliance with NEC 517.13.

- Identify the Circuit: At the panelboard, identify the branch circuit supplying the patient care space. Verify the panelboard equipment grounding terminal or bus is available and that the panelboard enclosure and grounding/bonding connections are installed to provide an effective ground-fault current path per Article 250 (panelboards are normally provided with grounding/bonding provisions required by the NEC).

- Confirm the Insulated EGC: Visually confirm that an insulated, green-jacketed conductor is installed with the branch circuit conductors. This is the insulated EGC required to be installed with the branch conductors.

- Verify the Metallic Ground Path: Inspect the raceway system. Ensure metallic conduits, fittings, and boxes are continuous, metallic, and properly coupled to form a continuous low-impedance path from the outlet to the panelboard; this path typically satisfies the NEC

treatment of metallic raceways or armor as an equipment grounding conductor. - Check Terminations: At the outlet, verify both grounding paths are terminated properly. The insulated EGC should be connected to the receptacle’s grounding terminal; the metallic raceway must be bonded to the metal outlet box. In typical installations, an equipment bonding jumper or listed method is used to ensure the receptacle grounding terminal is effectively connected to the box and to the equipment grounding path(s).

- Test for Low Impedance (Best Practice): While the NEC does not require a low-resistance ohm measurement for every installation, using an appropriate low-resistance instrument to confirm continuity and low impedance of both paths is a professional best practice and provides strong verification of installation integrity.

Special Considerations for Critical Care (Category 1) Spaces

The NEC includes additional measures to manage hazards in critical care areas; however, specific solutions (for example, a patient equipment grounding point or a particular bonding arrangement) may be implemented as permitted measures depending on facility decisions and the exact occupancy classification.

Special Protection in Wet Procedure Locations (NEC 517.20)

For designated wet-procedure locations within critical care areas, NEC 517.20 calls for special protection against electric shock. The Code lists acceptable approaches: isolated power systems (IPS) that remain in operation during a single line-to-ground fault and inherently limit ground-fault currents, or circuits protected by ground-fault circuit-interrupter (GFCI) devices where an interruption of power is acceptable.

When an IPS is used, it is an ungrounded (isolated) system that limits available fault current on a first line-to-ground fault. A line isolation monitor (LIM) is used to continuously monitor system isolation and provide an alarm when a first fault occurs; the LIM typically does not interrupt power on the first fault, which helps avoid unsafe interruptions during critical procedures. The NEC provides design and installation requirements for isolated power equipment and references listing requirements for that hardware.

Key Takeaways for NEC 2023 Healthcare Grounding

As a professional electrician, keep these points top of mind when working in healthcare facilities:

- Redundancy is Required for Patient Care Circuits: NEC 517.13 requires providing both a metallic-path grounding means (metal raceway or armor) and an insulated EGC installed with the branch conductors for patient care branch circuits (subject to limited exceptions).

- The Insulated EGC Is a Required Component: The Code requires an insulated EGC installed with the branch conductors; a metallic raceway alone does not satisfy the instruction to provide the insulated conductor as part of the branch wiring.

- Equipotential Measures Reduce Hazard: Bonding and patient equipment grounding points provide an equipotential approach that minimizes voltage differences between conductive surfaces in the patient vicinity.

- Different Categories, Different Measures: Understand the different requirements for patient care categories — for example, wet procedure locations in Category 1 may need IPS or GFCI protection depending on the circumstance.

- Secure Terminations Matter: Proper installation and secure terminations of all grounding paths are essential to maintain a low-impedance path and reliable protection.

Primary Sources for Healthcare Electrical Safety

For further reference and authoritative guidance, consult the official code documents and the applicable standards:

- NFPA 70: National Electrical Code (NEC), specifically Article 517 and related sections in Article 250.

- NFPA 99: Health Care Facilities Code for additional healthcare performance and safety requirements.

Frequently Asked Questions (FAQ) about NEC 2023 Grounding and Bonding

- 1. What is the main change to NEC 2023 grounding and bonding for patient care areas?

- The 2023 NEC did not introduce a sudden change, but it clarified and reinforced existing requirements (particularly how branch circuits for patient care spaces must provide robust grounding). The emphasis in Article 517 is on providing both the metallic-path grounding means and an insulated EGC with the branch conductors to ensure a reliable low-impedance grounding scheme.

- 2. Is a metal conduit by itself a sufficient equipment grounding conductor in a patient care vicinity?

- Not by itself to meet all of 517.13’s requirements. While a properly installed metallic conduit or metallic cable armor qualifies as an equipment grounding conductor under NEC 250.118, 517.13 also requires an insulated equipment grounding conductor to be installed with the branch conductors. So the conduit qualifies as one path, but the code expects the installation of the insulated conductor as the additional path unless a specific exception applies.

- 3. What is the purpose of an equipotential approach in a hospital room?

- Bonding conductive surfaces in the patient care vicinity (for example, receptacle grounds, metal frames, and other conductive surfaces) to a common reference reduces voltage differences between them. The equipotential approach helps prevent small currents from passing through a patient between two different surfaces, improving patient safety.

- 4. Do all hospital rooms require an Isolated Power System (IPS)?

- No. The NEC requires either GFCI protection or an IPS only for specified wet-procedure locations in Category 1 areas where the facility determines that continuity of power cannot be tolerated to be lost. IPS is a permissible alternative where power loss from a protective device would endanger care; it is not mandated for every hospital room.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)