Fused vs. Non-Fused Disconnects: How to Choose Correctly

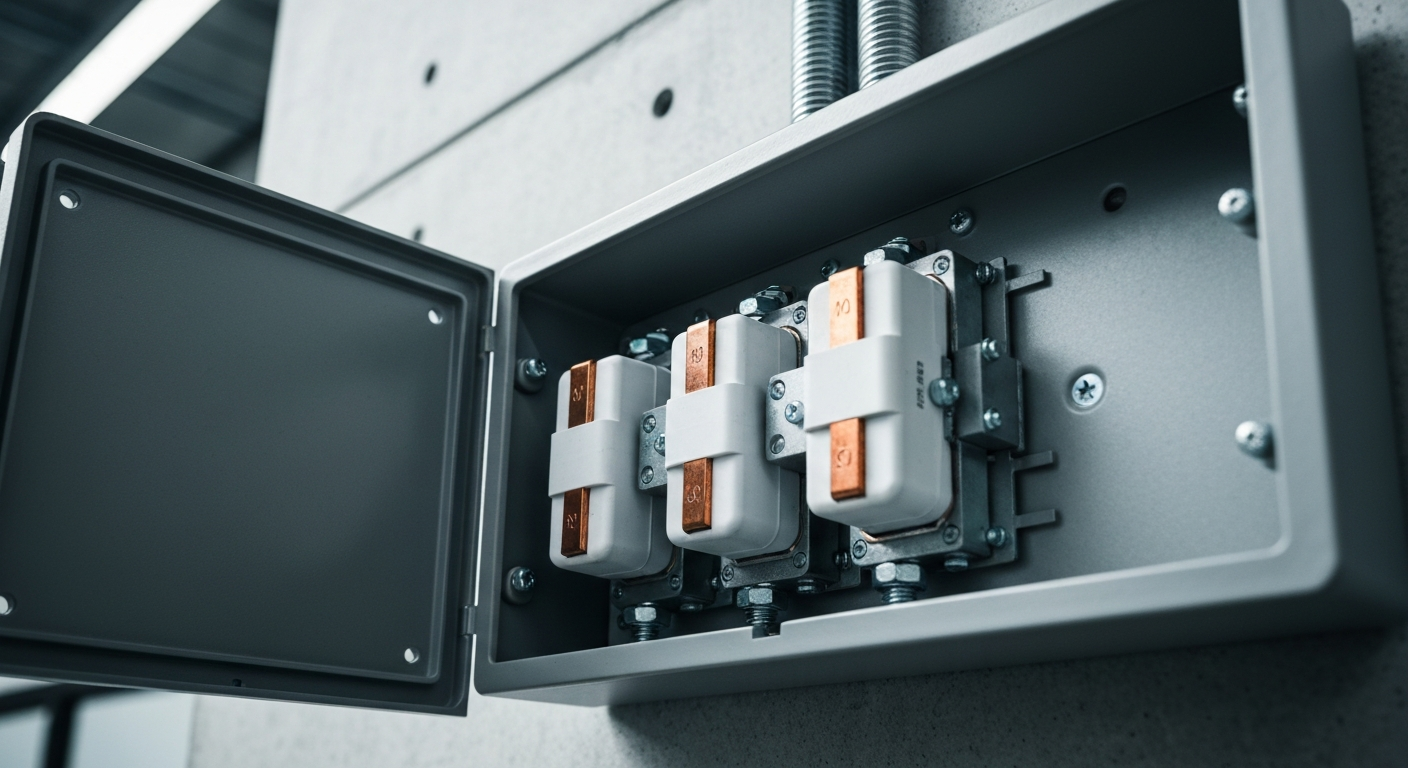

The Core Difference: Fused vs Non-Fused Disconnect

The primary decision when considering a fused vs non fused disconnect centers on one critical function: overcurrent protection. A fusible safety switch incorporates both a disconnecting means and an overcurrent protective device (OCPD) in the form of fuses within a single enclosure. This provides local, dedicated protection for the connected equipment. In contrast, a non-fusible safety switch is purely a mechanical device for isolating a circuit; it offers no overcurrent protection and must rely on an upstream overcurrent protection device, such as a circuit breaker in a panelboard. The choice depends entirely on whether the specific point in the electrical system requires its own branch-circuit protection or if adequate protection is already provided upstream, compliant with all National Electrical Code (NEC) requirements.

What is a Disconnect Switch? A Quick Refresher

At its core, a disconnect switch, or disconnecting means, is a device designed to safely de-energize a circuit or piece of equipment for service and maintenance. Its primary function is safety, ensuring a clear, visible break in the circuit. This is fundamental to all safe work practices, especially those involving lockout/tagout (LOTO) provisions as mandated by OSHA and NFPA 70E. Correctly identifying the purpose and location of these devices is a foundational skill for any electrician, and the code provides specific guidance on how to properly identify disconnecting means in the 2023 NEC. These requirements are not limited to large machinery; the NEC also has distinct rules for equipment like disconnecting means for fluorescent and LED luminaires, underscoring their broad applicability.

The Fusible Safety Switch: Combining Isolation and Protection

A fusible safety switch is the go-to solution when you need to provide or supplement protection at the equipment level. It acts as both a switch and a local OCPD, making it an essential component for providing branch-circuit protection where none exists or where specific protection characteristics are required.

The fuses inside the switch are selected to match load characteristics and to have sufficient interrupting capacity for the available fault current at that location (often expressed as an ampere interrupting rating, AIC or IR). This selection is directly related to the overall short-circuit current rating (SCCR) of the equipment assembly. For complex systems, selecting specific fuse types (e.g., time-delay for motors) may be part of a larger coordination study to ensure that the nearest upstream OCPD trips first during a fault, minimizing downtime for the rest of the facility.

The Non-Fusible Safety Switch: Relying on Upstream Protection

A non-fusible safety switch provides the same essential “off-on” and LOTO capabilities but contains no protective elements. Its use is predicated on the existence of properly sized upstream overcurrent protection. These are common in applications where the disconnect is located relatively close to the panelboard that feeds it. For example, an air handler on a roof (an HVAC service disconnect) might be fed from a dedicated circuit breaker in a panel just inside the building. In this scenario, the breaker provides the OCPD function, and the non-fusible disconnect simply provides a safe, local means of de-energizing the unit for a technician.

Critical Factors in Choosing: A Side-by-Side Comparison

Making the right choice between fused and non-fused options requires analyzing several factors specific to the installation.

Application-Specific Disconnects: HVAC, Motors, and Water Heaters

Different equipment types have unique requirements. A simple resistive load like a water heater disconnect may only require a basic non-fusible switch if protection is provided at the panel. However, a motor disconnect switch is more complex. Motors have high inrush currents, often necessitating time-delay fuses in a fusible switch to avoid nuisance tripping. Furthermore, the switch itself may need to be a specific motor rated switch, capable of interrupting the locked-rotor current of the motor it controls, per NEC Article 430.

Service Entrance and Ampacity Considerations

At the main service, a service entrance disconnect is required to de-energize the entire premises. For a typical residential or small commercial building, this might be a 200 amp service disconnect. Whether this is fused or non-fused depends on the system design. In many modern installations, the main disconnect is a main circuit breaker integrated into the panelboard, which serves as both the disconnecting means and the OCPD. In other designs, particularly in older commercial facilities, a large fusible switch may serve this role. The NEC has strict rules for how many service disconnecting means are allowed, which must be followed; for more on that topic see how many service disconnecting means are allowed.

Step-by-Step Guide to Disconnect Switch Sizing

Performing correct disconnect switch sizing is a critical task governed by the NEC. Follow these steps for a compliant installation:

- Determine the Load: Calculate the full-load amperes (FLA) for motors or the total connected load for other equipment. Identify if the load is continuous or non-continuous.

- Consult the NEC for Ampacity and Rating: For motor disconnects, apply NEC Article 430.110 (a disconnect current rating not less than 115% of motor FLA). For continuous loads and conductor sizing, use the NEC conductor ampacity provisions (conductors serving continuous loads are commonly sized at 125% of the continuous load). In all cases, the disconnect and conductors must be rated for the calculated load.

- Decide: Fused or Non-Fused: Evaluate the system. Is there adequate, properly rated upstream overcurrent protection? If not, or if local protection is desired for coordination or maintenance, select a fusible safety switch. Otherwise, a non-fusible safety switch is sufficient.

- Verify SCCR and Interrupting Rating: Determine the available fault current at the point of installation. The selected disconnect and its fuses (if applicable) must have an interrupting capacity or short-circuit rating equal to or greater than the available fault current.

- Select the Enclosure: Choose the proper enclosure type (NEMA/indoor-outdoor rating) based on the exposure and environment of the installation.

Key Takeaways for Field Application

As a professional electrician, keeping these points in mind will ensure safe and compliant installations:

- A fusible safety switch is a two-in-one device, providing both isolation and local branch-circuit protection.

- A non-fusible safety switch is for isolation only and is entirely dependent on a properly sized upstream overcurrent protection device.

- Always verify specific National Electrical Code (NEC) requirements for the application, whether it’s a motor disconnect switch, an HVAC service disconnect, or a main service disconnect.

- The physical integrity and safety features are paramount. Ensure the switch has adequate lockout/tagout (LOTO) provisions and the correct NEMA enclosure types for its location.

- Never underestimate the importance of the interrupting rating / SCCR. Installing a switch with an inadequate rating is a major safety hazard.

Understanding these nuances is key to professional excellence. Make the right component choices with our advanced electrical design courses.

Primary Sources

This article references standards and best practices established by the following organizations. Always consult the latest editions for official requirements.

Frequently Asked Questions (FAQ)

- 1. What is the main difference in the fused vs non fused disconnect debate?

- The core difference is the inclusion of an overcurrent protective device (OCPD). A fusible safety switch contains fuses to protect the downstream circuit and equipment from overloads and short circuits. A non-fusible safety switch does not contain fuses and only provides a means to manually open or close the circuit, relying completely on an upstream breaker or fuse for protection.

- 2. When is a fusible safety switch required for a motor disconnect switch?

- A fusible safety switch is used for a motor disconnect switch when local branch-circuit short-circuit and ground-fault protection is needed (see NEC Article 430 provisions on branch-circuit protection). While the fuses provide short-circuit protection, separate motor overload protection (e.g., overload relays or an integral device in the motor) still must be provided per NEC motor protection rules; fuses typically do not substitute for motor overload devices.

- 3. Can a non-fusible safety switch be used as a 200 amp service disconnect?

- Not by itself. NEC 230.91 requires the service overcurrent protective device to be either integral to the service disconnecting means or located immediately adjacent to it. A non-fusible safety switch does not include an OCPD, so it cannot serve as the required service OCPD unless a separate listed OCPD is provided immediately adjacent (or the switch and OCPD are part of a listed assembly). Placing a non-fusible exterior switch feeding an interior panel without an adjacent listed OCPD would not meet the NEC requirement.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)