What Mistakes Do Electricians Make When Tying Cables?

Introduction

Making cable tying mistakes can lead to serious NFPA 70 (NEC) compliance issues, compromised system longevity, and fire risks. While a fundamental task for electricians, these errors can undermine safety and code compliance. This guide details common cable tying errors, their consequences, and professional practices to ensure safe, NEC-compliant installations.

The Most Frequent Errors

1. Over-tightening

Over-tightening cable ties compresses conductors and can damage insulation. NEC requires conductors be protected from physical damage (see NEC Article 300), and over-tightening can create damage that violates those protection requirements. Even if the damage is not immediately apparent, compromised insulation shortens service life and increases the risk of faults.

2. Ignoring Ampacity De-rating

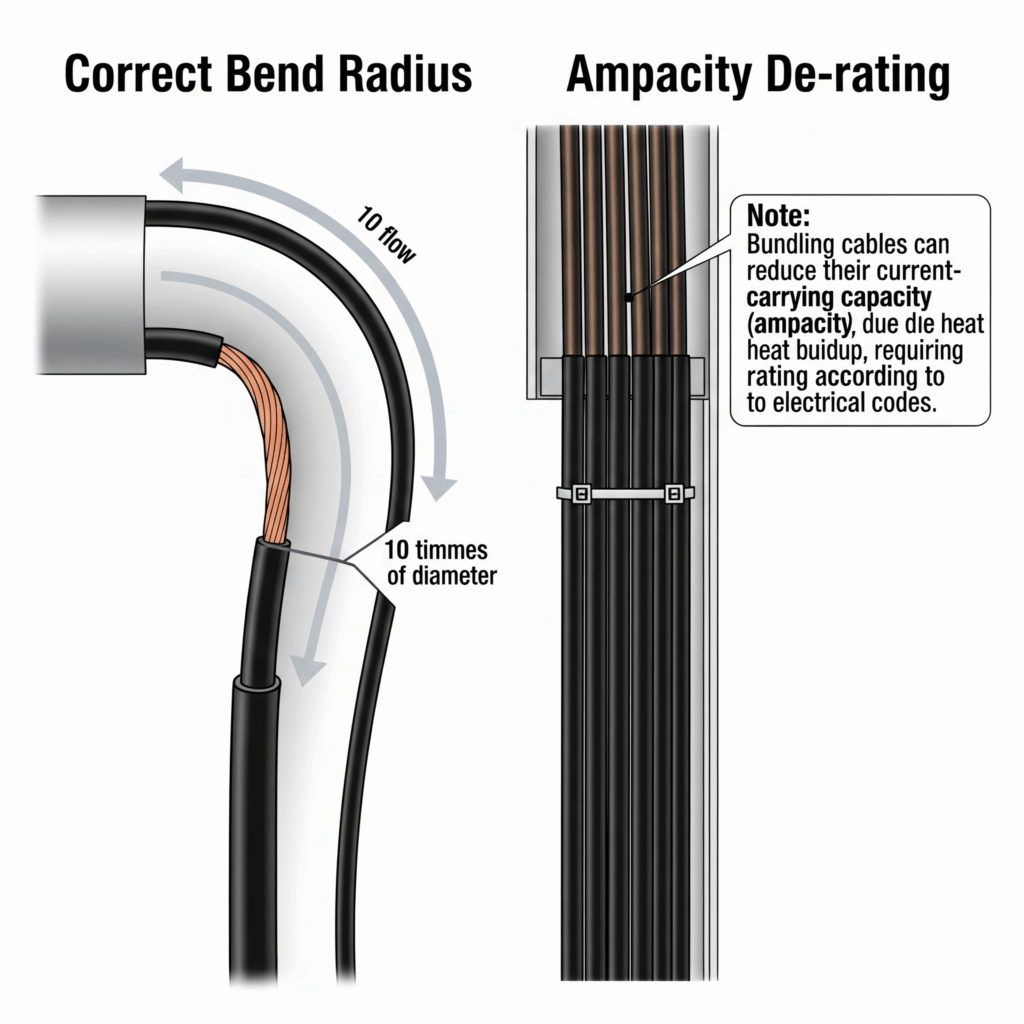

Bundling more than three current-carrying conductors traps heat and requires ampacity adjustment under NEC 310.15 (Adjustment Factors). Ignoring that de-rating risks overheating. For example, 14 AWG copper conductors have a 60°C ampacity of 15 A; using the adjustment factor for 10 conductors (50%) reduces the allowable ampacity to about 7.5 A, so bundling that many conductors without upsizing or separating them would not meet ampacity requirements for a 15 A circuit. Always apply the NEC ampacity adjustment tables and select conductor sizes or separation methods accordingly.

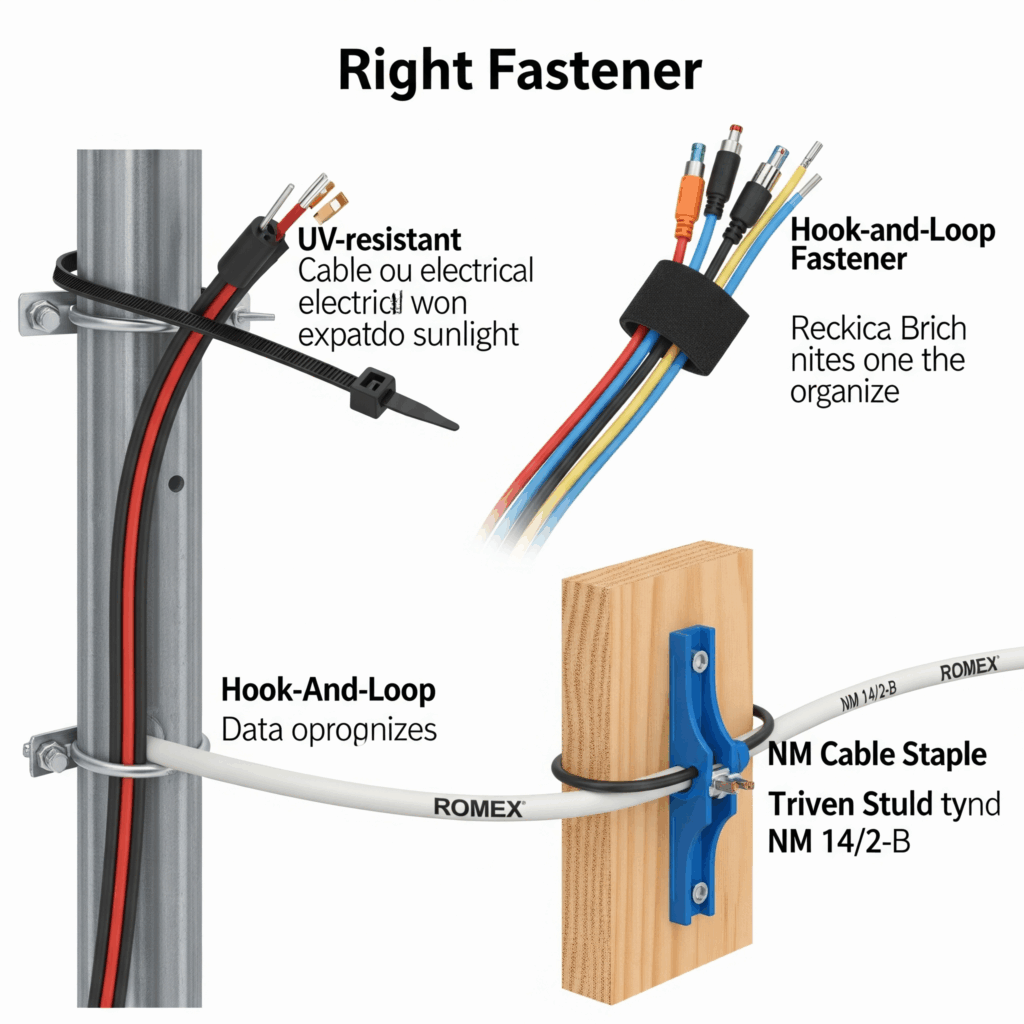

3. Using the Wrong Fastener

Select fastening hardware appropriate to the environment and cable type. Materials exposed to sunlight must be suitable for sunlight exposure; ties and fasteners for outdoor use should be sunlight/UV resistant. Excessive pressure on data cables can impair performance; use hook-and-loop or other manufacturer-recommended fasteners and avoid overtightening. For nonmetallic-sheathed (NM) cables, secure supports per NEC 334.30 — generally at intervals not exceeding 1.4 m (4 1/2 ft) and within 300 mm (12 in.) of boxes.

Preventing Cable Tying Errors for NEC Compliance

Adopting NEC-compliant cable tying practices prevents hazards and ensures safe, code-compliant installations. Follow these strategies to meet NFPA 70 and NFPA 70E safety expectations.

Professional Best Practices and Safety Protocols

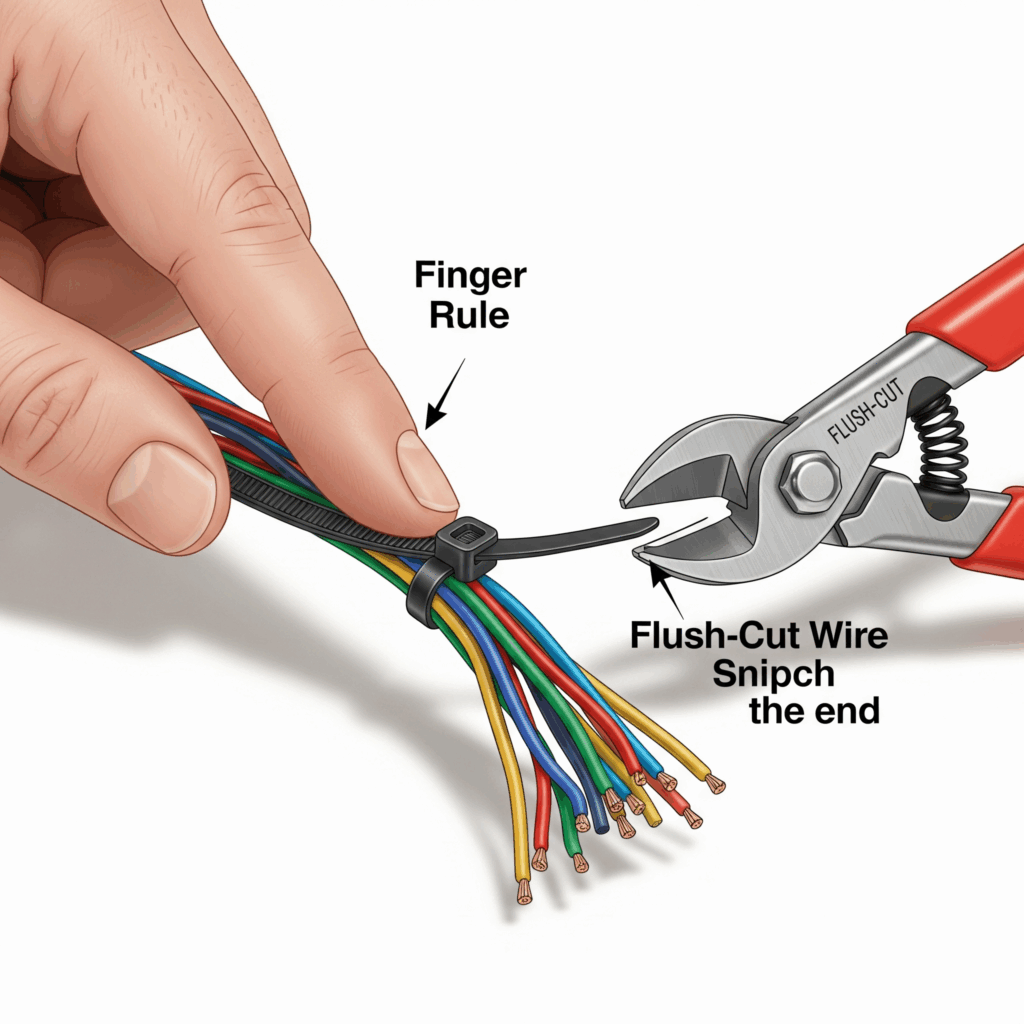

Finger Rule: When tensioning ties, allow enough clearance (for example, that a finger can be placed under the tie) to avoid over-tightening and damage. NEC requires protection from physical damage; using a tactile check helps protect insulation. Use flush-cut tools to remove tie tails and prevent sharp edges that could abrade insulation or injure workers.

Right Fastener: Use materials rated for the exposure — sunlight-resistant ties for outdoors and ties listed for plenum use where required. For communications cables, follow Article 800 guidance on mechanical execution and, in plenums, use accessories listed for low smoke/heat release. For NM (Romex) securement, follow NEC 334.30 spacing.

NEC Compliance: Apply ampacity correction and adjustment factors in NEC Article 310 when bundling conductors, secure and support raceways and cables per NEC 300.11, and follow the specific cable article (for example NEC Article 334 for NM cable) for bend radii and other handling requirements.

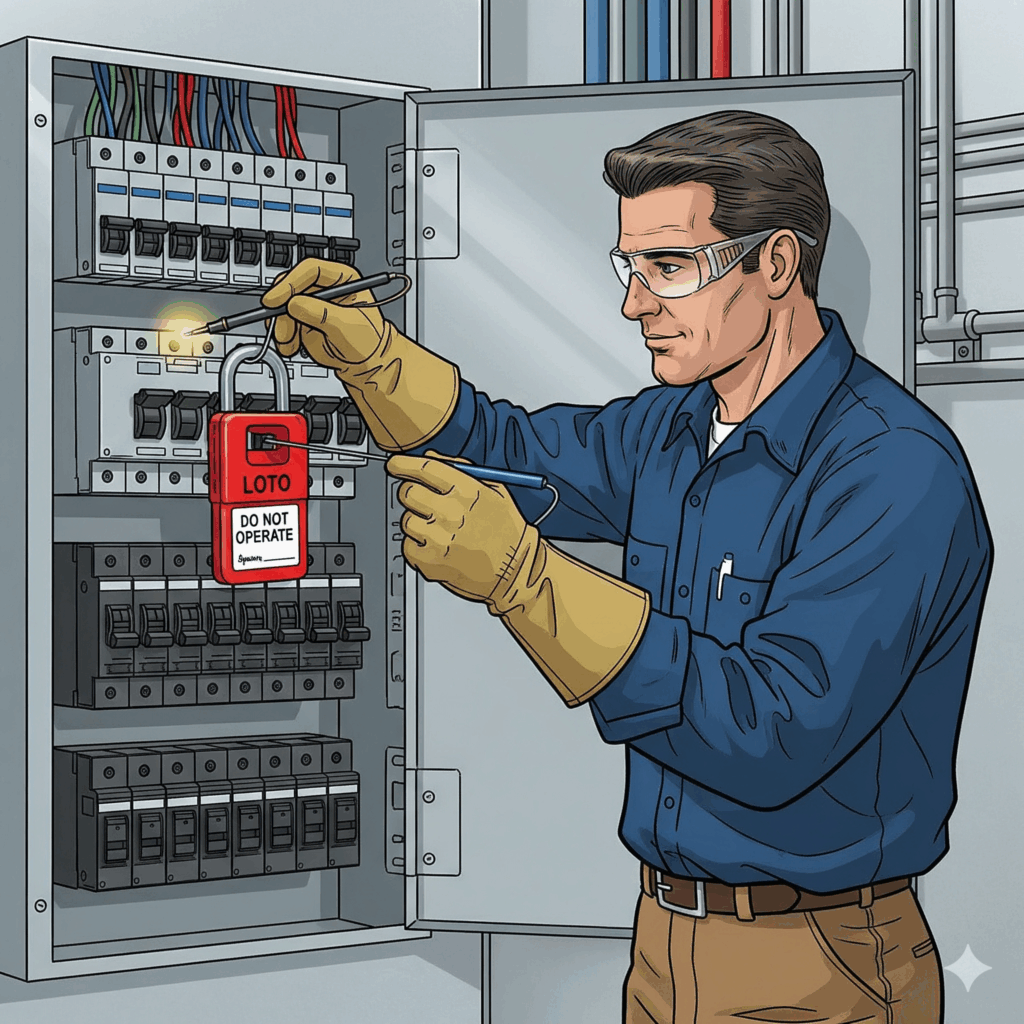

De-energize: Verify circuits are de-energized with appropriate test equipment and follow lockout/tagout procedures (refer to OSHA lockout/tagout guidance and NFPA 70E for electrical safety practices). Example: De-energize a residential panel before terminal work or handling energized conductors.

PPE: Wear appropriate insulating gloves, eye protection, and other personal protective equipment as required by NFPA 70E and employer procedures when working near energized conductors.

Example: In a commercial retrofit, bundling multiple current-carrying conductors or cables in a raceway can require ampacity adjustment per NEC 310.15 adjustment factors; use appropriate supports (per NEC 300.11) to maintain bend radius and ensure junction boxes remain accessible (NEC 314.29). If the installation includes cable assemblies with armor or multiple conductors, consult the specific cable article (for example Article 330 for Type MC) to determine ampacity treatment and listing limitations.

Conclusion

Correct cable tying is a hallmark of professional skill, ensuring NFPA 70 compliance and safety. By avoiding over-tightening, applying ampacity adjustments when bundling conductors, and using proper fasteners and supports, electricians create reliable, maintainable installations that protect users and equipment.

Take the next step in your professional growth! Visit Expert CE (https://expertce.com/) for all your continuing education needs.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)