Identifying and Using Lineman’s, Diagonal & Needle-Nose Pliers

Mastering the Essentials: A Guide to Electrician Pliers Types

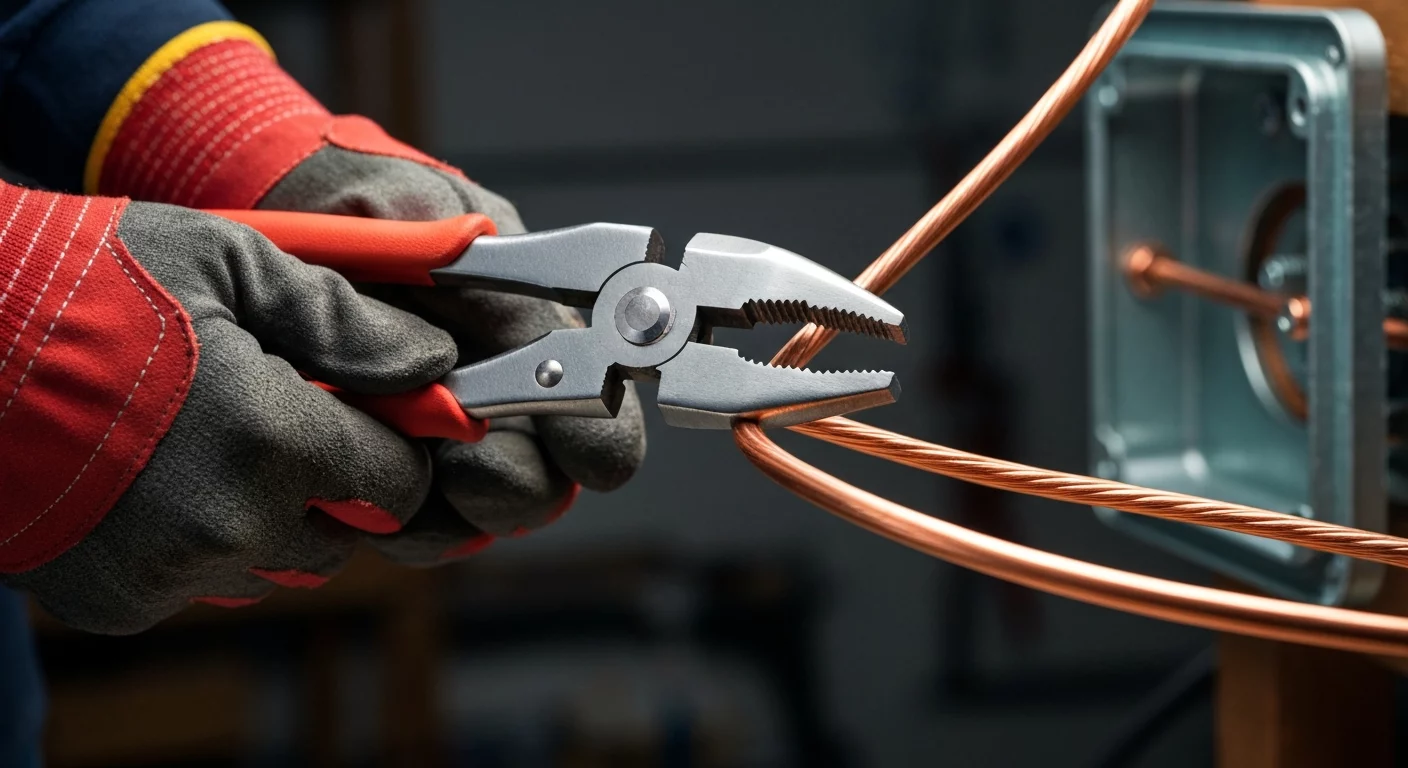

For any professional in the electrical trade, from a residential electrician to a master electrician, a deep understanding of your tools is non-negotiable. Among the most fundamental of these are pliers. Knowing the primary electrician pliers types and their specific applications is crucial for safety, efficiency, and quality workmanship. The three indispensable pliers that form the foundation of any electrician’s toolkit are Lineman’s, Diagonal, and Needle-Nose pliers. Each is engineered for a distinct set of tasks, from leveraging brute force for twisting wires and fish tape pulling to executing precise cuts and manipulations in tight spaces. Choosing the right tool, such as one with a high-leverage design or certified insulated grips, is a hallmark of a true professional and essential for any electrical installation project.

The Core Trio: Understanding the Main Electrician Pliers Types

While countless specialty pliers exist, the daily work of most electricians revolves around three core designs. A journeyman electrician relies on this trio for the vast majority of tasks, and even a master electrician overseeing complex projects will have them within reach. These professional hand tools are the building blocks of efficient electrical work.

Lineman’s Pliers: The All-in-One Powerhouse

Often considered the most iconic tool in an electrician’s belt, Lineman’s pliers (or combination pliers) are the heavy-duty workhorses of the trade. Their robust construction and multifunction jaw design make them incredibly versatile. The flat, serrated gripping surface at the tip provides a powerful hold for grabbing, bending, and twisting conductors. Just behind the tip is a circular, toothed grip often used for turning nuts or even light-duty conduit reaming.

The core feature for many is their ability to perform heavy-duty cutting, thanks to the integrated cutting edges. A high-leverage design, which places the rivet closer to the cutters, multiplies hand force, allowing users to slice through tough materials more easily. They are also the go-to tool for grabbing and pulling steel fish tapes through conduit and are indispensable for making secure, twisted connections on solid conductors when used properly and within the tool’s rated capacity.

Diagonal Pliers (Side-Cutters): Precision in Cutting

Also known as diagonal-cutting pliers or side-cutting pliers, these tools have one primary function: to make exceptionally clean and precise cuts. Unlike the cutters on Lineman’s pliers, which are designed for power, the angled jaws of diagonal pliers are built for accuracy. They allow the user to cut wires flush against a surface, such as when trimming conductors inside a junction box or snipping off the ends of zip ties.

The hardened cutting edges are designed to meet at the tip first, providing superior control for snipping small-gauge wires in crowded panels. While some may attempt light wire stripping with them, it’s not their intended purpose and can easily nick the conductor. For a professional electrical installation, using a dedicated stripping tool is always the better practice.

Needle-Nose Pliers: For Finesse and Reach

When the job requires precision in tight or awkward spaces, needle-nose pliers are the solution. Their long, tapered jaws excel at tasks that larger pliers simply cannot handle. A residential electrician will find them essential for forming loops in conductors to fit around screw terminals on outlets and switches. They are also perfect for retrieving dropped screws, positioning small components, and bending wires with a high degree of control.

Many models incorporate a small cutting edge near the pivot and some even feature sections for terminal crimping, adding to their utility. The unique jaw design makes them a critical tool for working inside control panels, light fixtures, and other confined electrical enclosures where precision is more important than power.

Advanced Features and Safety Considerations for Professional Hand Tools

Modern pliers offer more than just basic functionality. Advances in materials and design have led to features that enhance safety, performance, and user comfort—key considerations for anyone serious about their career, from those just leaving an electrician school to seasoned veterans.

The Critical Role of Insulated Grips and VDE Ratings

Working on or near energized circuits demands strict adherence to electrical safety procedures. Pliers with properly rated insulated grips are essential. Not all dipped handles provide electrical protection. Professionals should use tools tested and certified to recognized insulated-tool standards (for example IEC 60900 / VDE), which are intended to provide an insulating barrier for tools rated for use up to 1,000 V. Test voltages used for type testing are higher (for example before certification a withstand test at several kilovolts is performed), but the important metric for work is that the tool is certified for a 1,000 V rating under the applicable standard. Always follow NFPA 70E safe work practices and employer policies for live work—NEC (NFPA 70) addresses installation requirements, while NFPA 70E and OSHA address safe work practices.

High-Leverage Design and Ergonomics

The term high-leverage design refers to the relocation of the plier’s pivot point. By moving it closer to the jaws, the tool provides a significant mechanical advantage, reducing the amount of force required for cutting and gripping. This innovation means less hand fatigue over a long day of repetitive tasks, a crucial benefit for any electrician’s long-term health. Ergonomic handle designs further enhance comfort and control, preventing slippage and reducing strain on the wrist and hand.

Step-by-Step Guide: Using Lineman’s Pliers for Twisting Wires

A perfectly twisted splice ensures maximum surface contact between conductors for a secure and low-resistance connection. Lineman’s pliers are the ideal tool for this fundamental task.

- Prepare the Conductors: Begin by stripping the insulation from the wires you intend to join. Ensure you strip them to the proper length for the connector you will be using. For detailed guidance on this crucial first step, see our article on how to properly strip and terminate wire.

- Align the Wires: Hold the stripped wires parallel to each other, with the ends of the insulation lined up evenly.

- Grip Securely: Using the square nose of your lineman’s pliers, firmly grip the conductors about halfway down the stripped length. Your grip should be tight enough to prevent the wires from slipping.

- Twist Evenly: Begin twisting the pliers clockwise. Maintain firm pressure and a steady pace to create a tight, uniform spiral. Continue twisting until the wires are tightly bound together up to the tips.

- Trim the End: Use the cutting edges of your lineman’s pliers to snip off the uneven tips of the newly twisted wires, creating a clean, flat end.

- Cap the Connection: Finish the splice by screwing on a properly sized wire connector. The connector should cover all bare copper and form a secure mechanical and electrical bond. To learn more about selecting the right connector, review our guide to wire connectors.

Beyond the Basics: Pliers and the Modern Electrician

As you advance in your electrician training, you’ll find that while this core trio is essential, specialized tools also have their place. For high-volume work, a dedicated wire stripping machine can offer speed and consistency that manual stripping cannot match. However, the versatility and reliability of fundamental pliers are irreplaceable. As technology evolves, so do hand tools, with many manufacturers offering multi-function designs that incorporate features like bolt cutters, crimpers, and strippers into a single tool. As you progress from an electrician school to a working professional, having the right tools is paramount. Make sure your tool bag has everything you need to start your career. Continuing education through online electrical courses will also keep you updated on the latest tools and techniques in the industry.

Key Considerations When Selecting Electrician Pliers

- Match the Tool to the Task: Use Lineman’s for leverage and heavy-duty work, Diagonal pliers for clean cuts, and Needle-Nose for precision and reach. Using the wrong tool compromises quality and safety.

- Prioritize Safety: For any work near potentially live circuits, use insulated tools that are certified to an appropriate insulated-tool standard (for example IEC 60900/VDE) rather than relying on generic plastic-dipped handles.

- Invest in Quality: Look for durable, hardened steel construction and a high-leverage design. A quality tool is a long-term investment in your efficiency and safety.

- Consider Ergonomics: Comfortable, non-slip grips reduce hand fatigue during repetitive tasks like terminal crimping or twisting wires, which is critical for career longevity.

Primary Sources

For official regulations regarding tool and workplace safety, professionals should always refer to the following authorities:

- Occupational Safety and Health Administration (OSHA) – Hand and Power Tools Standard (29 CFR 1926 Subpart I)

- National Fire Protection Association (NFPA) – NFPA 70E®, Standard for Electrical Safety in the Workplace®

Frequently Asked Questions about Electrician Pliers Types

- What are the three essential electrician pliers types every journeyman electrician should own?

- Every journeyman electrician should have a quality set of Lineman’s pliers for gripping and twisting, Diagonal (side-cutting) pliers for precise cuts, and Needle-Nose pliers for work in confined spaces. These three tools cover over 90% of common daily tasks.

- Why is a high-leverage design important for Lineman’s pliers?

- A high-leverage design moves the tool’s pivot point closer to the cutting jaws. This provides a mechanical advantage, significantly increasing the cutting power and reducing the hand strength needed. This makes it easier to cut through larger wires and reduces fatigue over the workday.

- Are pliers with insulated grips enough for electrical safety standards?

- No. While insulated grips are essential, they must be properly tested and certified to an insulated-tool standard (for example IEC 60900 / VDE) for use on or near energized systems. Professionals should follow NFPA 70E and OSHA guidance for energized work rather than assuming any single tool feature alone provides all necessary protection.

- Can I use lineman’s pliers for wire stripping?

- While it is technically possible to use the cutting edge of lineman’s pliers for wire stripping, it is highly discouraged. It is very difficult to control the pressure, often resulting in nicks or cut strands, which can compromise the connection. A dedicated wire stripper or a wire stripping machine for production work is the professional choice for clean, damage-free results.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)