How to Troubleshoot and Repair Electric Recliner Wiring

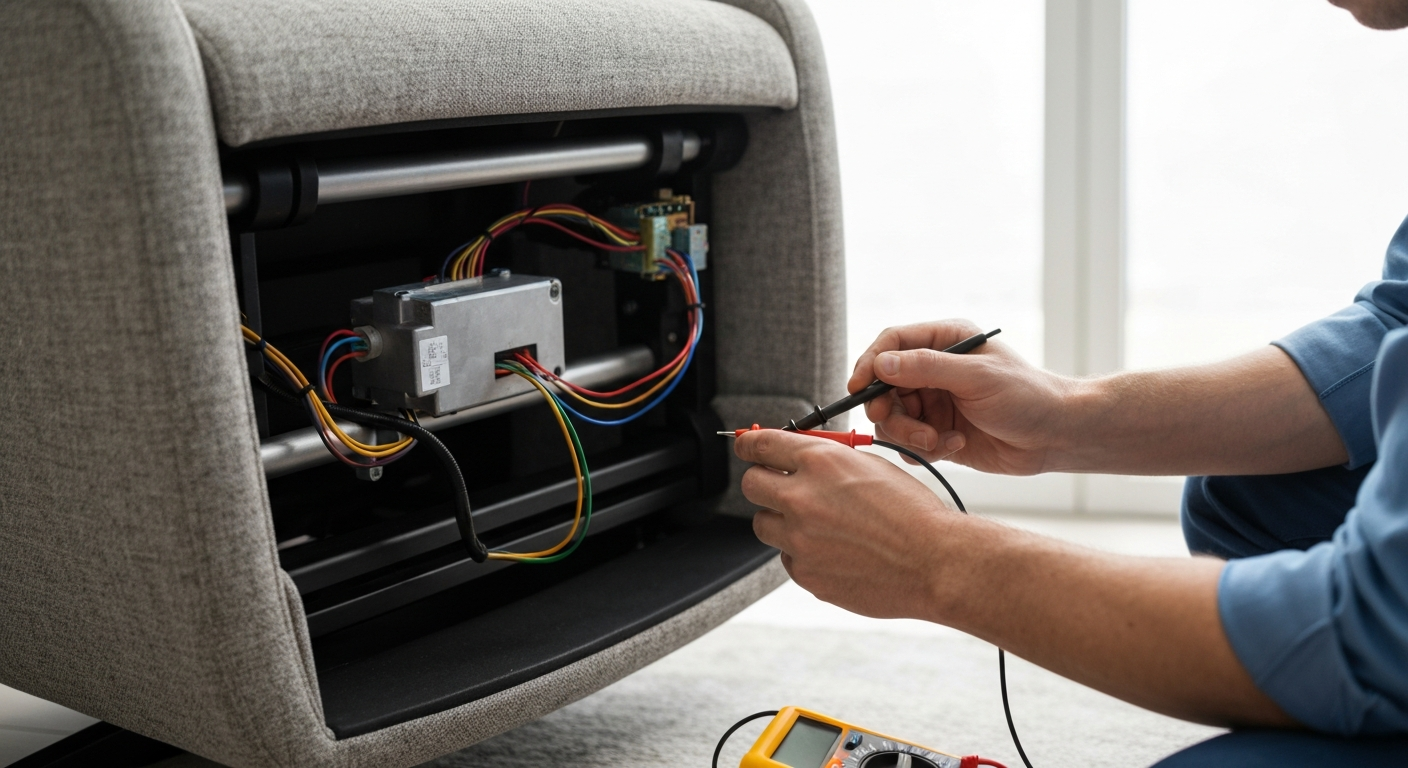

Performing an electric recliner repair is a systematic process that licensed electricians are uniquely qualified to handle. The core procedure for effective power recliner electrical diagnostics involves first isolating the chair from its power source. Begin with a visual inspection of all wiring for frays, pinches, or loose connections. Next, use a multimeter to test the output voltage of the wall transformer (after unplugging and ensuring safe test setup). If the transformer is functional, proceed to test the handset control switch for continuity. Finally, with all safety precautions in place, test the actuator motor by briefly applying a known good low-voltage DC source (within the motor’s rated voltage) directly to its terminals to confirm operation. Many of these supplies are Class 2 power-limited sources (NEC Article 725) — verify their ratings and listing. This methodical approach to low-voltage motor diagnostics and recliner actuator troubleshooting allows you to efficiently pinpoint the faulty component—be it the power supply, switch, wiring, or motor—and replace it with the correct, listed replacement part. This skill is a valuable extension of a professional electrician’s expertise in troubleshooting electrical systems.

Understanding the Core Components of an Electric Recliner Chair

While they seem simple, modern electric recliner chairs are comprised of several key electrical components working in unison. As an electrician, you’ll recognize the basic principles, but it’s crucial to understand how they apply specifically to motorized furniture. A typical electric recliner chair or recliner chair electric model contains a low-voltage system that is generally safe but requires a precise diagnostic approach.

The primary components you will encounter include:

- AC/DC Power Supply (Transformer): This is typically a wall-wart style transformer that plugs into a standard 120 V outlet and steps the voltage down to a low-voltage DC output. Common recliner supplies are in the 12–24 V DC range (24 V DC is frequently used), though other voltages are possible — always verify the transformer’s nameplate rating and manufacturer documentation before testing or replacing it.

- Handset Control (Switch): The wired or wireless remote that the user interacts with. It’s fundamentally a momentary switch that sends a signal to the motor. The integrity of the handset control wiring is a common point of failure.

- Linear Actuator Motor: This is the heart of the recliner’s movement. It’s a low-voltage DC motor combined with a gearbox and a screw drive to create linear motion, pushing and pulling the chair’s mechanism.

- Wiring Harness: A set of cables connecting the power supply, handset, and motor. These often use specific plug-and-play connectors.

Always prioritize the use of UL-certified recliner components or OEM replacements for any replacement to ensure the repair meets established safety benchmarks.

Safety First: Essential Precautions for Motorized Furniture Repair

Safety is paramount in any electrical work, and motorized furniture repair is no exception. While these systems are low-voltage, improper handling can still damage components or create a fire hazard. Before beginning any diagnostic work, always unplug the recliner’s power supply from the wall outlet. This eliminates any risk of shock or accidental activation of the motor, which could cause a pinch hazard.

It’s also critical to adhere to professional standards. While many furniture-level components are not covered by the NEC in the way building wiring is, applying the professional mindset highlighted by standards and listing requirements (for example the practical guidance in the linked NEC-focused course) offers a useful framework for assessing the safety and quality of replacement components. This professional diligence is key even in non-permitted contexts like furniture repair. Adhering to low-voltage wiring standards for routing and securing wires post-repair is essential for a durable and safe outcome.

Step-by-Step Guide to Power Recliner Electrical Diagnostics

A systematic approach is the fastest way to a successful diagnosis. Follow these steps for comprehensive multi-meter furniture testing and troubleshooting.

- Initial Visual Inspection: Before grabbing your meter, turn the chair over to get a clear view of the undercarriage. Look for the most common culprits: wires that have been pinched, stretched, or chewed by pets. Check that all connectors are securely seated.

- Test the Power Supply: Plug the transformer into a known good outlet. Set your multimeter to the DC voltage setting. Carefully touch the probes to the output terminals of the transformer’s connector (after confirming the transformer is unplugged while you prepare and then safely powering it for the measurement). You should get a reading that matches the output rating printed on the transformer (e.g., 24 V DC if indicated). A reading of zero or a significantly lower voltage indicates a need for troubleshooting the supply, wiring, or fusing and may point to a recliner transformer replacement.

- Perform Continuity Testing Recliner Switch: Unplug the handset control from the main wiring harness. Set your multimeter to the continuity setting (the one that beeps). Test the switch by placing your probes on the output pins of the handset’s connector and pressing the recline and incline buttons. You should have continuity when a button is pressed and an open circuit when it is not. If the switch fails this test, it needs replacement.

- Directly Test the Linear Actuator: This step definitively confirms if the motor is operational. Disconnect the motor from the wiring harness. Using a known good low-voltage DC power source (such as a bench supply set to the actuator’s rated voltage or a known-good, listed recliner transformer), carefully apply power briefly to the two pins on the motor’s connector (observe polarity and rated voltage). If the motor extends, reverse the polarity of your leads; it should then retract. If the motor does not move under the correct rated voltage, you can confirm it is the point of failure, necessitating a linear actuator repair or replacement. This is the essence of practical low-voltage motor diagnostics.

Distinguishing Recliner Systems from Other Electrical Assemblies

As a professional electrician, your experience spans a vast array of electrical systems. It’s useful to contextualize the simplicity of a recliner’s circuit against other equipment you might encounter. A recliner power supply schematic is fundamentally a simple, direct-control circuit. This is far less complex than the high-amperage demands of a commercial electric griddle or the robust, three-phase requirements of a heavy-duty pool pump electric motor.

The low-voltage DC wiring in a recliner also presents different considerations than outdoor or specialized systems. It’s a world away from the high-pulse output of an electric fence charger or the specialized, weatherproof mc4 connectors used in solar panel arrays. Even other consumer products, such as a battery-powered ego electric lawn mower or a remote-controlled electric fire pit, involve more complex battery management systems or ignition controls. Recognizing these differences allows you to apply your diagnostic principles efficiently without overcomplicating the task at hand. Your expertise lies in adapting your foundational knowledge to the specific system in front of you, and an electric recliner repair is a perfect example of this adaptability. As you expand your skillset to include appliance and furniture electrical repair, you’ll find these jobs to be quick and profitable additions to your service offerings.

Advanced Troubleshooting: From Recliner Actuator Troubleshooting to Power Lift Chair Service

Some situations require a deeper level of analysis. A power lift chair service, for example, often involves two or more actuators—one for the recline function and one for the lift function. In these cases, troubleshooting lift chair wiring means isolating and testing each motor circuit independently. If one function works and the other doesn’t, it often points to a specific motor, a corresponding section of the handset control, or a control box that directs power to the correct motor.

Advanced recliner actuator troubleshooting might involve checking for mechanical binds that cause the motor to draw excessive current, tripping an internal thermal protector. This can present as an intermittent failure where the chair works for a moment and then stops. A careful inspection of the chair’s mechanical frame is necessary in conjunction with electrical testing. For any complex electric recliner repair, obtaining the manufacturer’s recliner power supply schematic can be invaluable, saving you significant diagnostic time.

Key Takeaways for Electric Recliner Repair

- Always disconnect the power supply from the wall outlet before beginning any electric recliner repair or inspection.

- A thorough visual inspection for pinched, frayed, or disconnected wires is the most effective first step.

- Use a multimeter for systematic multi-meter furniture testing of the transformer, switch, and motor to isolate the faulty component.

- For replacements, insist on OEM or UL-certified recliner components to guarantee safety, compatibility, and a lasting repair.

- Remember that a power lift chair service may involve multiple motors and more complex handset control wiring or a central control box.

Primary Sources

Frequently Asked Questions (FAQ)

- What are the first steps in electric recliner repair if the chair is completely dead?

- If an electric recliner chair is completely unresponsive, start by checking the power source. Ensure the wall outlet is working and that the transformer is securely plugged in. Next, perform the step-by-step power recliner electrical diagnostics: test the transformer’s DC voltage output with a multimeter. If the transformer has no output, it is a likely culprit and should be replaced with a properly rated, listed replacement; also check fuse(s), wiring, and the outlet/GFCI feeding the transformer before concluding the transformer alone has failed.

- How does troubleshooting lift chair wiring differ from a standard electric recliner?

- The main difference in troubleshooting lift chair wiring is the presence of at least two motors and often a more complex control box. A standard recliner usually has one motor. In a lift chair, you must diagnose the lift and recline circuits separately. If only one function fails, you can focus your testing on the specific motor, wiring, and handset switch section related to that function, which is a key part of power lift chair service.

- Is it better to attempt a linear actuator repair or just replace the entire unit?

- In most cases, it is more efficient and reliable to replace the entire linear actuator. A failed actuator typically has an internal motor or gearbox issue. Attempting a linear actuator repair is often impractical as replacement parts are not readily available, and reassembling the unit correctly can be difficult. Replacement ensures a reliable fix, especially when dealing with the physical loads the actuator must handle.

- What tools are essential for power recliner electrical diagnostics?

- The most essential tool is a quality multimeter capable of reading AC/DC voltage and continuity. Additionally, a basic set of hand tools like screwdrivers and wire strippers is useful. For directly testing motors, a reliable low-voltage DC power source, such as a benchtop supply or a known-good recliner transformer, is invaluable for performing definitive low-voltage motor diagnostics.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)