A Guide to Personal Protective Grounding for Linemen

Why Personal Protective Grounding is a Non-Negotiable Safety Practice

Working on supposedly de-energized lines without proper protection is a gamble with lethal stakes. A line can become unexpectedly energized through various means, including switching errors, contact with an adjacent live circuit, lightning, or induced voltage from nearby energized high-voltage lines. When this happens, current follows available paths to ground; without a deliberate low‑impedance path (temporary protective grounds and bonding), a worker or unbonded object could be part of the fault path. The two primary electrical hazards in this scenario are step and touch potential.

- Step Potential is the voltage difference between the feet of a person standing near a grounded object that has become energized. Current flowing into the earth creates voltage gradients, and even stepping near a fault can cause dangerous current to pass through the lower body.

- Touch Potential is the voltage difference between an energized object and the feet of a person touching it. If a lineman touches a vehicle or structure that has become accidentally energized, their body can complete the circuit to the ground, resulting in severe injury or electrocution.

The core principle behind personal protective grounding is to establish temporary protective grounds and bonding jumpers to create deliberate low‑impedance connections in the work zone.

Understanding Core Principles: EPZ, Fault Current, and Bonding

Effective grounding is built on several key electrical concepts. Understanding these is crucial for any lineman or journeyman electrician responsible for job site safety.

Creating an Equipotential Zone (EPZ)

An Equipotential Zone (EPZ) (termed equipotential plane in NEC definitions) is central to personal protective grounding: conductive objects in the immediate work area are bonded together to minimize voltage differences between them. Think of a bird on a wire: because both of its feet are at the same potential, no current flows through its body. An EPZ is created by bonding conductive parts together using temporary bonding jumpers or a common attachment point (for example, a temporary bonding bar or a properly prepared grounding point bonded to the system grounding electrode) and, where used, supplemental grounding mats or conductors to provide a consistent equipotential area.

The Destructive Power of Fault Current

Fault current is the large magnitude of current that can flow during a short-circuit or ground-fault condition; NEC/Article 240 and 250 emphasize determining available fault current when selecting and coordinating protective devices and grounding/bonding conductors. Temporary grounding assemblies and bonding conductors must be selected so they will withstand the available fault current and provide an effective low-impedance path for operation of overcurrent devices.

Grounding vs. Bonding: What’s the Difference Here?

While often used together, grounding and bonding serve distinct purposes. For an in‑depth look at definitions under the NEC, see Grounding vs. Bonding: Understanding the NEC Rules in Article 250. In the context of lineman safety, the terms are applied as follows:

- Grounding means connecting the circuit or equipment to a grounding electrode system so that equipment and conductive parts are at a defined reference to earth; temporary grounding for line work uses temporary bonding and grounding assemblies rather than relying on a single permanent electrode. For more information on installation of grounding electrodes, see How to Install a Ground Rod Based on NEC Requirements.

- Bonding connects conductive parts together (truck frames, poles, conductors, cluster/bonding bars, etc.) so that there is a low‑impedance path between them; this is how an equipotential area for the crew is produced. For additional discussion, see grounding and bonding principles.

Key Standards and Regulations: OSHA, IEEE, and ASTM

The procedures and equipment for personal protective grounding are addressed by regulation and standards that guide safe practice and equipment performance.

- OSHA 1910.269: This regulation addresses safety for electric power generation, transmission, and distribution work and includes requirements for safe work practices when performing line clearance and switching operations; it is an applicable regulatory requirement for powerline work. (OSHA 1910.269)

- IEEE Std 1048: This guide provides industry best practices on protective grounding methods for power lines, including application, installation, and removal of temporary grounds and discussion of equipotential work practices. (IEEE Std 1048)

- ASTM F855: This standard covers specifications for temporary protective grounding equipment (manufacture and testing of clamps, ferrules, and grounding assemblies) used for power‑system grounding. (ASTM F855)

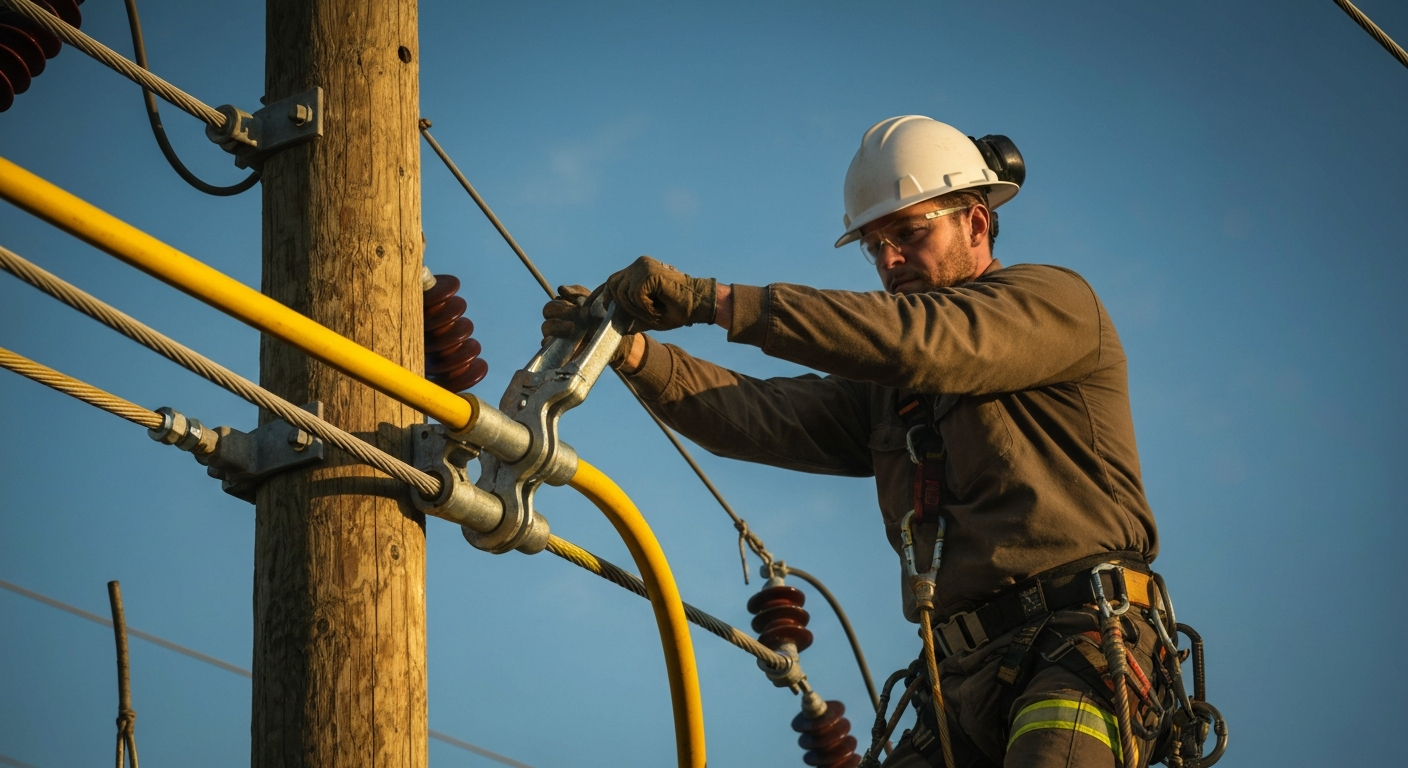

Step-by-Step: Applying Temporary Protective Grounds Safely

Procedures and sequencing are emphasized by industry guidance. As a practical sequence for temporary protective grounds (consult your employer procedures, IEEE guidance, and OSHA rules for your work), consider:

- Test for Voltage: Before any work begins, use properly rated test equipment to verify that lines are de‑energized. Treat conductors as energized until verified and until temporary protective grounds and bonding are applied as required for the work. (OSHA 1910.269, IEEE 1048)

- Clean Connection Surfaces: Use an appropriate brush or method to prepare conductor and attachment points so metal-to-metal connections can be made for a low-impedance path.

- Connect to Ground First: Attach the first clamp of the grounding assembly to the designated grounding point or common bonding point (for example, a temporary bonding bar or a properly prepared grounding point bonded to the system grounding electrode).

- Connect to the Conductor: Using an approved hot‑stick or appropriate live‑line tool for the grounding assembly, connect the conductor‑side clamp to the de‑energized conductor; do not rely on hand contact for the clamp installation. (IEEE 1048)

- Apply to All Phases: Repeat the process for each phase or conductor in the work zone so that the bonded set provides the equipotential area.

- Removal (First On, Last Off): Remove conductor‑side clamps first using the live‑line tool, and disconnect the ground‑source clamps last, so the worker removing clamps is not the return path.

Master the principles of protective grounding to prevent electrical shock. Investing in your knowledge is the best way to ensure a long and safe career.

Advanced Methods and Ongoing Training

Methods such as placing temporary grounds on either side of a work site (bracket grounding) are used in practice to limit arcing and coordinate protective device operation; industry guidance such as IEEE 1048 describes these methods as options and provides recommended procedures for EPZ/bonding and other grounding techniques. Continuous training is essential for linemen, journeymen, and other electrical workers to stay current on procedures and standards; industry guidance and employer training programs aligned with OSHA and IEEE recommendations are appropriate ways to maintain competency. Understanding topics such as grounding electrode conductor and bonding jumper sizing is critical; NEC Article 250 provides prescriptive sizing (for example, 250.66, 250.102, 250.122) and these rules should be consulted for permanent grounding and bonding installations. For practical discussion, see NEC 250.66 Grounding Electrode Conductor Sizing.

Related Resources

Frequently Asked Questions (FAQ)

What is the main purpose of personal protective grounding?

The main purpose is to provide a low‑impedance path for fault current so that protective devices operate and to reduce step and touch potentials by bonding conductive objects in the work area.

How does an Equipotential Zone (EPZ) protect a journeyman electrician?

An EPZ protects an electrician by bonding conductive objects in the work area so there are minimal voltage differences between them; with bonding in place, a fault is much less likely to produce dangerous touch or step potentials within the bonded area.

What is the difference between step and touch potential?

Step potential is the voltage difference between a person’s feet as they stand near an energized object; touch potential is the voltage difference between an energized object a person touches and their feet. Both are recognized hazardous voltages that grounding and bonding seek to reduce (NEC guidance on grounding/bonding in Article 250).

Why do you need to ground de-energized lines?

Lines believed to be de‑energized are grounded temporarily to protect personnel because lines can be unexpectedly energized by switching errors, accidental contact with another live line, lightning, or induced voltages; standards and regulations emphasize testing, bonding, and temporary grounding for safe work (OSHA and IEEE guidance).

What does the ampacity of grounding cables signify?

The ampacity or rating of a grounding assembly indicates the level of current it can safely conduct; NEC Article 250 provides conductor and bonding size rules for permanent grounding and bonding (250.66, 250.102, 250.122), and standards such as ASTM F855 specify performance requirements for temporary grounding equipment.

Primary Sources

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)