How to Wire a Subpanel: NEC Compliance Guide

Understanding the Role of a Subpanel in an Electrical System

A subpanel, also commonly referred to as a panel sub, sub panel, or an electrical sub panel, is a smaller electrical panel that serves as a distribution point for a specific area or a set of high-demand loads. It receives power from the main service panel—often a 200 amp panel or a 200 amp main breaker panel—via a feeder circuit. The primary purpose of these subpanels is to add circuits when the main breaker panel 200 amp is full or to provide a convenient power distribution and disconnection point for a separate area, such as a detached garage, workshop, or a new addition. Installing an outdoor sub panel is also a common solution for supplying power to outdoor equipment like pool pumps or HVAC units, but remember outdoor installations have additional listing and environmental requirements.

Pre-Installation: Planning for NEC Compliance

Before a single wire is pulled, thorough planning is essential to ensure the installation complies with the National Electrical Code (NEC). This phase prevents costly mistakes and ensures the system’s safety and functionality.

Panelboard Load Calculation and Sizing

The first step is a detailed panelboard load calculation to determine the required capacity. You must calculate the anticipated load for the new circuits to correctly size the subpanel itself and the feeder. Common installations include a 50 amp sub panel for a dedicated appliance or tool circuit, a 60 amp subpanel for a small workshop, or a 100 amp sub panel for a larger outbuilding or addition. The panel must have adequate physical space for all required breakers, including any future needs. While you might be working off a 200 amp electrical panel, the subpanel’s capacity is determined by its specific loads, not the size of the main service. A 100 amp breaker panel is a very common choice for residential additions. The panel itself will either be a main lug only panel or may come with a main breaker installed—choose the type appropriate for your installation and local code.

Feeder Conductor Sizing and Selection

Once the load is known, you must perform an ampacity calculation for feeders. This determines the correct gauge for the electrical feeder conductors. The calculation must account for conductor material (copper or aluminum), insulation type, ambient temperature, and the number of current-carrying conductors in the raceway. It’s also critical to calculate for voltage drop on feeder; keep voltage drop low (industry practice is to aim for about 3% total; plan conductor sizes accordingly). For nearly all modern installations, a 4-wire feeder installation (two hots, one neutral, one equipment ground) is required so the neutral and equipment grounding conductors remain separate in the subpanel.

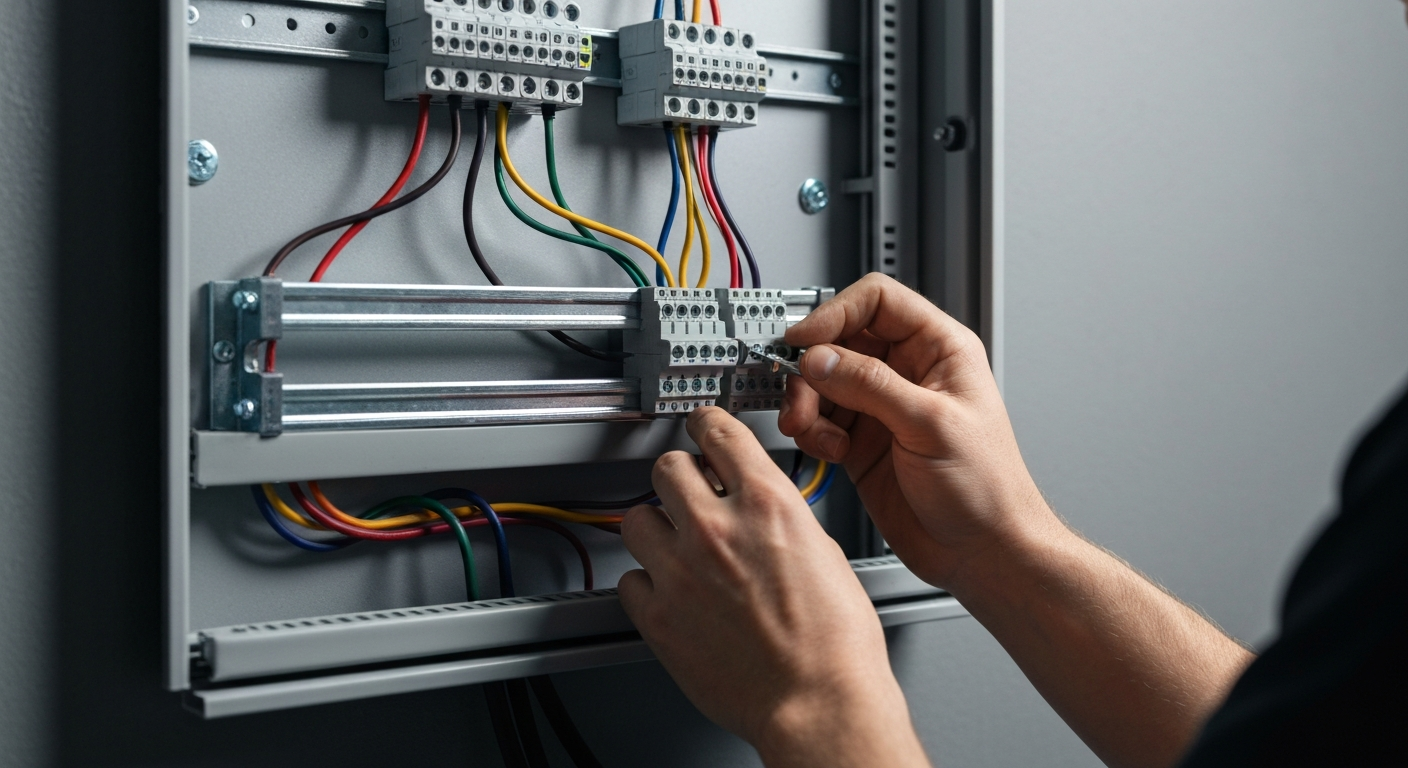

Step-by-Step Sub Panel Wiring Guide

With planning complete, you can proceed with the physical installation. Adhering to these steps ensures a compliant and safe setup. For worker safety, understanding new requirements is key, especially how 2023 NEC panelboard barriers improve worker safety when accessing energized parts.

- Safety First: De-energize the Main Panel. Turn off the main breaker in the 200 amp breaker box (or other main panel). Use a voltmeter and a reliable circuit tracer or breaker finder to verify that power is off at the location where you will be installing the feeder breaker, and always follow local lockout/tagout procedures.

- Mount the Subpanel. Securely mount the new electrical panel box. For installations in different building envelopes, be aware of how 2023 NEC panelboard enclosure requirements are different to ensure proper environmental protection. You might be installing a standard 100 amp breaker box or a specific Square D 200 amp panel as a large subpanel, but select the enclosure and listing appropriate for indoor or outdoor use.

- Run the Feeder Cable. Route the 4-wire feeder cable from the main panel to the subpanel location. Ensure it is properly supported and protected from physical damage per NEC Chapter 3 and the cable or raceway product listing.

- Connect the Feeder at the Main Panel. In the main panel, connect the two ungrounded (hot) conductors to a properly sized 240 V breaker sized to match the feeder wire ampacity (for example, 60 A or 100 A as determined by the load and conductor ampacity). The size must match the feeder wire ampacity, providing correct overcurrent protection requirements. Connect the neutral conductor to the neutral bus bar and the equipment grounding conductor to the equipment grounding bus bar. In a main panel, these bars are typically bonded by the main bonding jumper.

- Connect the Feeder at the Subpanel. At the subpanel, connect the two hot conductors to the main lugs or main breaker as provided by the panel. This is a common arrangement in a main-lug-only panel (no main disconnect inside the subpanel), but make sure the panel type matches the installation and local code requirements. Connect the neutral feeder conductor to the neutral bus bar.

- CRITICAL: Isolate Neutral and Ground. This is the most crucial step in sub panel wiring. The neutral bus bar must be isolated from the panel enclosure so that the neutral is not bonded to the box. Remove the factory-installed bonding jumper (often a green screw or a strap) that connects the neutral bar to the panel can. Install a separate equipment grounding bar, bonded directly to the metal enclosure, and connect the feeder’s equipment grounding conductor to this bar. This practice of separating neutral and ground is required except where the Code permits otherwise (for example, the main service bonding is at the service disconnect only).

- Install Branch Circuit Breakers. Install the new breakers for the branch circuits. This could be a 15 amp circuit breaker for lighting, a 20 amp breaker for outlets, or a 30 amp breaker for a dryer. You might install a 30 amp double pole breaker for a 240 V load or a specific 40 amp breaker for an appliance. Ensure you are using the correct type for the application (standard thermal-magnetic, GFCI/AFCI, etc.) and that breakers are listed for the panel. Even a 70 amp breaker might be used for a large load—size everything to ampacity and device ratings, and ensure correct overcurrent protection and equipment compatibility.

- Torque, Label, and Cover. Use a torque wrench to tighten all terminal lugs to the manufacturer’s specifications (see NEC requirement to follow manufacturer termination instructions). This is one of the most overlooked but critical steps. Create an accurate panel schedule, clearly identifying each circuit. Knowing how to properly label switchgear, switchboards, and panelboards per NEC 2023 is a professional standard. Finally, install the electrical panel cover or electrical panel box covers.

The Critical Importance of Grounding and Bonding

The rules for grounding and bonding are what separate a safe subpanel installation from a hazardous one. The goal is to provide a single grounded conductor path back to the service with the system bonding (neutral-to-ground bond) located at the service disconnect only, and to ensure equipment grounding conductors provide an effective fault-current path back to the source.

Subpanels in Detached Buildings: NEC 250.32 Requirements

When installing a subpanel in a detached building, NEC 250 requirements for buildings supplied by feeders apply. A local grounding electrode system (for example, ground rods) is normally required at the detached building, and you must run the equipment grounding conductor with the feeder. The equipment grounding conductor provides the effective fault-return path and should be connected to the grounding electrode conductor and electrode at the detached building in the manner required by the Code (and the neutral remains isolated at the subpanel unless the feed is a separately derived system where other rules apply).

Common Breaker and Panel Considerations

Professionals must be familiar with a wide array of products and troubleshooting scenarios. Navigating breaker types, brands, and legacy systems is part of the job.

- Breaker Compatibility: Always use circuit breakers specifically listed or classified for the panel. Do not assume a particular brand will fit; only breakers listed or classified for your panel are permitted. Using the wrong breaker in an unlisted combination is a code violation and a fire hazard. If you are unsure, check the panel labeling for approved breaker types or the manufacturer’s documentation.

- Legacy Panels: When working in older homes, you may encounter obsolete or unsafe panels. Panels like some Federal Pacific or Zinsco-era equipment are commonly replaced due to well-documented problems; in those cases a full electrical panel replacement is often recommended. A qualified electrician should evaluate any suspect equipment and replace it when required for safety.

- Breaker Types & Sizes: Beyond amperage, know your types. A breaker intended for air-conditioning loads (sometimes labeled HACR) should be used as intended. A multiwire branch circuit requires a 2-pole common-trip breaker or two single-pole breakers with an approved handle tie to ensure simultaneous disconnection. Tandem breakers (skinny/space-saver) are allowed only where the panel listing permits them; check the panel listing and labeling.

- Troubleshooting: A common complaint is “breaker keeps tripping“. Common causes are overload, short circuit, or ground fault. After clearing a trip, if it persists investigate loads and wiring. Use proper diagnostic tools and remember a persistently tripping breaker often indicates a wiring fault rather than a bad breaker.

A properly installed subpanel provides tremendous flexibility and is a hallmark of professional electrical work. By adhering strictly to NEC guidelines—especially regarding feeder sizing, overcurrent protection, and the critical separation of neutral and ground—you ensure a safe and durable expansion of any electrical system. When you need to fix electrical panel issues or perform an upgrade, these principles are your foundation. Whether you are dealing with a 400 amp meter base, a 200 amp meter base with disconnect, or a simple electrical box 200 amp setup, the rules for subpanels remain consistent.

Ensure your panel installations are code-compliant. Learn more in our NEC courses.

Primary Sources

- NFPA 70, National Electrical Code (NEC), 2023 Edition

Frequently Asked Questions (FAQ)

- What is the most important rule for sub panel wiring regarding grounding?

- The single most important rule for sub panel wiring is separating neutral and ground. The neutral bus bar must be isolated (floating) from the subpanel’s metal enclosure, and the green bonding screw or bonding jumper must be removed. A separate ground bar must be installed and bonded to the enclosure for all equipment grounding conductors.

- My main panel is a 200 amp breaker panel; do I need a 200 amp subpanel?

- Not necessarily. The size of the subpanel (e.g., 50 amp sub panel, 100 amp sub panel) is determined by the panelboard load calculation for the specific circuits it will serve, not the size of the main 200 amp main breaker panel. The feeder breaker in the main panel, which protects the subpanel and its feeder wires, will be sized according to this load (for example, a properly calculated 100 amp breaker for a 100 A subpanel).

- Why does my circuit breaker keep tripping in my new subpanel?

- A breaker keeps tripping for three main reasons: overload (too much current draw), a short circuit (hot wire touches neutral or ground), or a ground fault. First, investigate the loads on that specific branch circuit. If the problem persists, you may need a qualified electrician to diagnose the issue. Learning how to test a breaker can help confirm whether the breaker itself is faulty, but persistent tripping usually indicates a wiring problem.

- Can I use any brand of breaker, like Eaton circuit breakers, in my Square D electrical panel?

- No. Use only circuit breakers that are listed or classified for use in your specific electrical panel board. If the panel label shows only certain manufacturers or classified breaker designations, those are the acceptable choices. Using an unapproved breaker in a panel not listed for it can be a code violation and may be unsafe. When in doubt, follow the panel manufacturer’s instructions or replace the panel with one that lists the desired breakers.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)