How to Wire a Hot Tub: Wire Size, GFCI, and Disconnects

Answering Your Core Question: Hot Tub Wiring Essentials

For a typical 240V, 50-amp spa, the required hot tub wire size is 6 AWG copper wire for the line conductors. This setup commonly uses a dedicated 240V circuit protected by a two-pole 50 A GFCI breaker (or equivalent listed spa panel protection). The entire electrical installation is governed by NEC Article 680, which outlines stringent rules for safety. Key among these are the hot tub disconnect requirements—mandating a readily accessible maintenance disconnect located at least 5 feet (1.5 m) horizontally from the inside wall of the tub—and requirements for an emergency shutoff in certain installations (see the paragraph below). All of these measures, together with comprehensive GFCI protection for spas, help to prevent shock hazards. A proper installation uses a 4-wire feeder (two hots, one neutral, one equipment ground) when the spa has 120 V components; strictly 240 V-only equipment may not require a neutral, so always follow the spa nameplate.

Introduction to NEC-Compliant Spa and Hot Tub Installations

As a licensed electrician, you know that specialty installations demand a higher level of scrutiny, and hot tubs are no exception. A safe and compliant electrical installation for a spa or hot tub goes far beyond simply connecting wires. It involves a detailed understanding of load calculations, grounding, bonding, and specific safety mechanisms mandated by the National Electrical Code (NEC), particularly the comprehensive rules laid out in NEC Article 680. This article provides an expert guide to navigating the critical aspects of hot tub wiring, ensuring your work is safe, efficient, and up to code.

Determining the Correct Hot Tub Wire Size and Circuit Requirements

The first step in any hot tub project is performing an accurate hot tub load calculation based on the manufacturer’s specifications. Most modern, full-sized hot tubs require a dedicated 240V circuit rated for 50 or 60 amps.

For the common 50-amp circuit, the typical 50 amp hot tub wire size is 6 AWG copper wire. This sizing is consistent with the conductor ampacity tables in the NEC for the common insulation types used in wet locations. It’s crucial to use conductors listed for wet locations and with the appropriate temperature rating for the terminations (for example, conductors marked THHN/THWN‑2). While 6 AWG is the typical choice, always verify against the spa’s nameplate and perform a voltage drop calculation, especially for long wire runs, to ensure performance and safety.

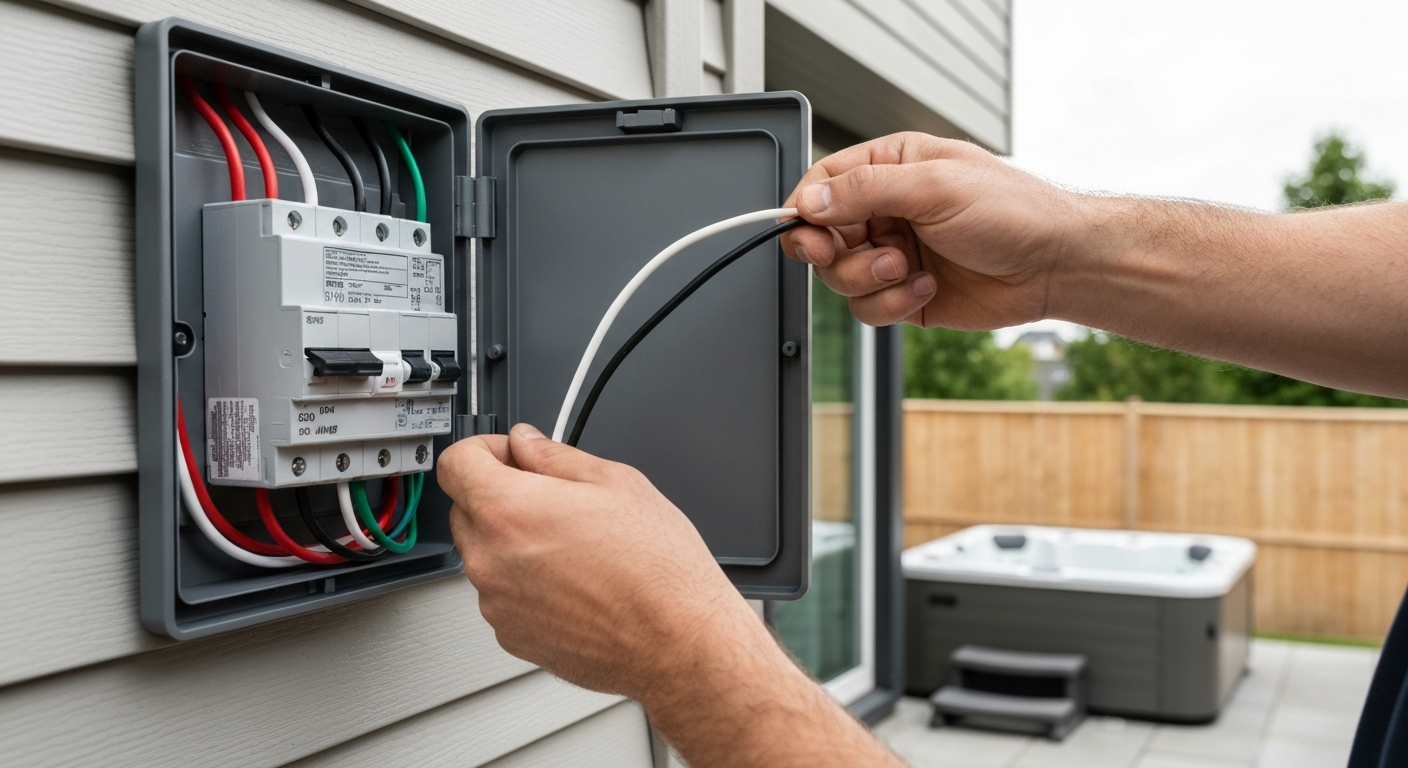

The Critical Role of GFCI Protection and Disconnects

Water and electricity are a dangerous combination, which is why NEC Article 680 places emphasis on ground-fault circuit interrupters (GFCI) and accessible disconnects.

Understanding Hot Tub Disconnect Requirements

Specifically, the maintenance disconnect required by the NEC must be located not less than 5 feet (1.5 m) horizontally from the inside wall of the tub. NEC 680.13 addresses maintenance disconnecting means and their location. NEC 680.41 requires a clearly labeled emergency shutoff adjacent to and within sight of the spa in many nonresidential installations — Understanding these emergency switch requirements is crucial for compliance.

Implementing Proper GFCI Protection for Spas

All 125 V receptacles within 3.0 m (10 ft) of a spa or hot tub and all electrical equipment associated with the spa (including pump motors and heaters where applicable) require GFCI protection for spas under the spa/hot tub provisions of Article 680. For a 240 V hard‑wired hot tub that includes 120 V loads or controls, this protection is commonly provided with a listed 2‑pole GFCI breaker at the source or with listed spa panels that incorporate GFCI protection. The 2023 NEC has clarified and added provisions for special-purpose ground‑fault protection for certain higher‑voltage circuits; for practical guidance on the 2023 changes and how they affect spas and hot tubs, review how 2023 NEC changes have impacted GFCI protection for spas and hot tubs. The NEC also includes provisions for special-purpose GFCI protection (SPGFCI) on some higher‑voltage circuits — how the 2023 NEC mandates SPGFCI protection for higher voltage circuits is a helpful primer on that topic.

Step-by-Step Voltage Drop Calculation for a 4-Wire Feeder

Ensuring the hot tub receives adequate voltage is critical for the longevity and performance of its components. A significant voltage drop can cause motors to overheat and fail. For a 4-wire feeder (L1, L2, N, G), you should perform a voltage drop calculation if the feeder length is substantial (e.g., over 100 feet). Follow these steps:

- Identify Key Variables: Find the Circular Mils (CMA) for your conductor from the NEC conductor properties tables. For 6 AWG copper wire, the CMA commonly used in calculations is 26,240. Determine the load amperage (I), one-way distance in feet (L), and the ‘K’ constant for copper (approx. 12.9).

- Apply the Formula: Use the voltage drop formula for a single-phase circuit: VD = (2 × K × I × L) / CMA.

- Calculate the Voltage Drop: For an example 50 A load on a 150‑foot run: VD = (2 × 12.9 × 50 × 150) / 26,240 ≈ 7.37 V.

- Determine Percentage: Percentage drop = (7.37 V / 240 V) × 100 ≈ 3.07%.

- Verify Compliance: NEC guidance recommends keeping branch‑circuit voltage drop near 3% for efficiency and motor performance. If the calculated drop exceeds your design target, upsize the conductor (for example to 4 AWG copper) to reduce voltage drop.

From Service to Spa: The Complete Electrical Path

A complete installation requires careful planning of the entire circuit path, from the main service to the spa’s terminal block.

Sourcing Power: Load Center vs Panelboard Considerations

The new hot tub circuit will typically originate from the main service load center. The new 2‑pole GFCI breaker must be compatible with the panel and will connect to the panel bus; ensure the panel has the physical space and the available capacity determined by proper service and load calculations.

Routing the Circuit: Feeder and Conduit Best Practices

The feeder running from the house to the spa disconnect is a critical part of the job. If run underground, this circuit is a feeder and must meet the NEC burial‑depth requirements in NEC Table 300.5. For many typical residential PVC conduit installations the minimum cover is often 450 mm (18 in.) under conventional conditions, but the table provides different depths for different methods and locations and must be consulted for the specific installation and local authority having jurisdiction. Plan the route, watch conduit fill limits, and avoid overfilling conduits to prevent overheating and difficult pulls.

Equipotential Bonding: A Non-Negotiable Safety Step

Often confused with grounding, equipotential bonding is a separate and mandatory safety system detailed in NEC Article 680.26. Its purpose is to connect all exposed metal components (ladders, drains, pump motors, and the bonding grid) together with a solid conductor sized by the Article (commonly a minimum solid 8 AWG copper bonding conductor in many spa and pool applications) to bring them to the same electrical potential. This prevents dangerous voltage gradients from forming in or around the hot tub, which can cause a shock even without a ground fault.

Key Takeaways for Hot Tub Wiring

- Confirm the Load: Always start with the manufacturer’s nameplate to determine the required amperage and voltage.

- Use the Right Wire: For most 50 A/240 V spas, the correct hot tub wire size for the hot conductors is 6 AWG copper; size the neutral only if the spa requires it.

- Install GFCI Protection: A 2‑pole GFCI breaker or a listed spa panel with integrated GFCI protection is required for spa equipment unless specifically excepted by the Article.

- Meet Disconnect Rules: The hot tub disconnect requirements are mandatory — provide the required maintenance disconnect and any required emergency shutoff per the Article.

- Don’t Forget Bonding: Equipotential bonding (properly sized bonding conductor connecting metal components) is essential.

- Consult the Code: When in doubt, NEC Article 680 is your source for spas and hot tubs; other NEC articles (e.g., 250, 300, 310) control grounding, raceway, and conductor sizing concerns.

Staying current with the NEC is essential for any professional electrician. Master specialty installations like pools and spas with our advanced NEC courses.

Primary Sources & Further Reading

For the most accurate and up-to-date requirements, always refer to the official source for the National Electrical Code:

- National Fire Protection Association (NFPA) – NFPA 70, National Electrical Code (NEC)

Frequently Asked Questions (FAQs)

- What is the standard 50 amp hot tub wire size?

- The standard 50 amp hot tub wire size for the hot conductors is 6 AWG copper wire. If the spa requires a neutral for 120 V loads, make the neutral the same size. The equipment grounding conductor must be sized per the NEC equipment‑grounding conductor table (commonly 8 AWG copper for a 50 A branch circuit); always confirm required grounding size in the NEC table and local code.

- What are the hot tub disconnect requirements according to the NEC?

- The hot tub disconnect requirements require a maintenance disconnect that is readily accessible and located not less than 1.5 m (5 ft) horizontally from the inside wall of the tub. NEC 680.13 covers maintenance disconnects, and NEC 680.41 covers emergency shutoff requirements in certain settings (see the Article for details and for exceptions when listed equipment includes integral protection).

- Does a hot tub require a dedicated 240V circuit and a 4-wire feeder?

- Yes, virtually all modern hot tubs require a dedicated 240 V circuit. If the spa contains 120 V loads (controls, lights), a 4‑wire feeder—two hot conductors (L1, L2), a neutral, and an equipment grounding conductor—is required. If the spa is strictly 240 V and the manufacturer does not call for a neutral, a 3‑wire supply (two hots plus ground) may be permitted, but always follow the spa nameplate and Article 680 requirements.

- How does NEC Article 680 impact a hot tub electrical installation?

- NEC Article 680 is the primary governing standard for the entire electrical installation of a hot tub, swimming pool, or spa and covers overhead conductor clearances, underground wiring, GFCI requirements, disconnect locations, and equipotential bonding. Consult Article 680 and the referenced NEC chapters (e.g., Articles 250, 300, 310) for grounding, raceway, and conductor requirements.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)