How Should Electrical Cables Be Tied?

Introduction

Proper cable tying and management are critical for safe, compliant, and maintainable electrical installations. Beyond aesthetics, organized wiring ensures safety, longevity, and serviceability, aligning with NFPA 70 (National Electrical Code, NEC) standards. Improper practices risk heat buildup, insulation damage, and difficult maintenance, leading to hazards or code violations. This guide details professional cable management techniques, NEC requirements, and safety protocols for electricians.

Why Cable Management Matters

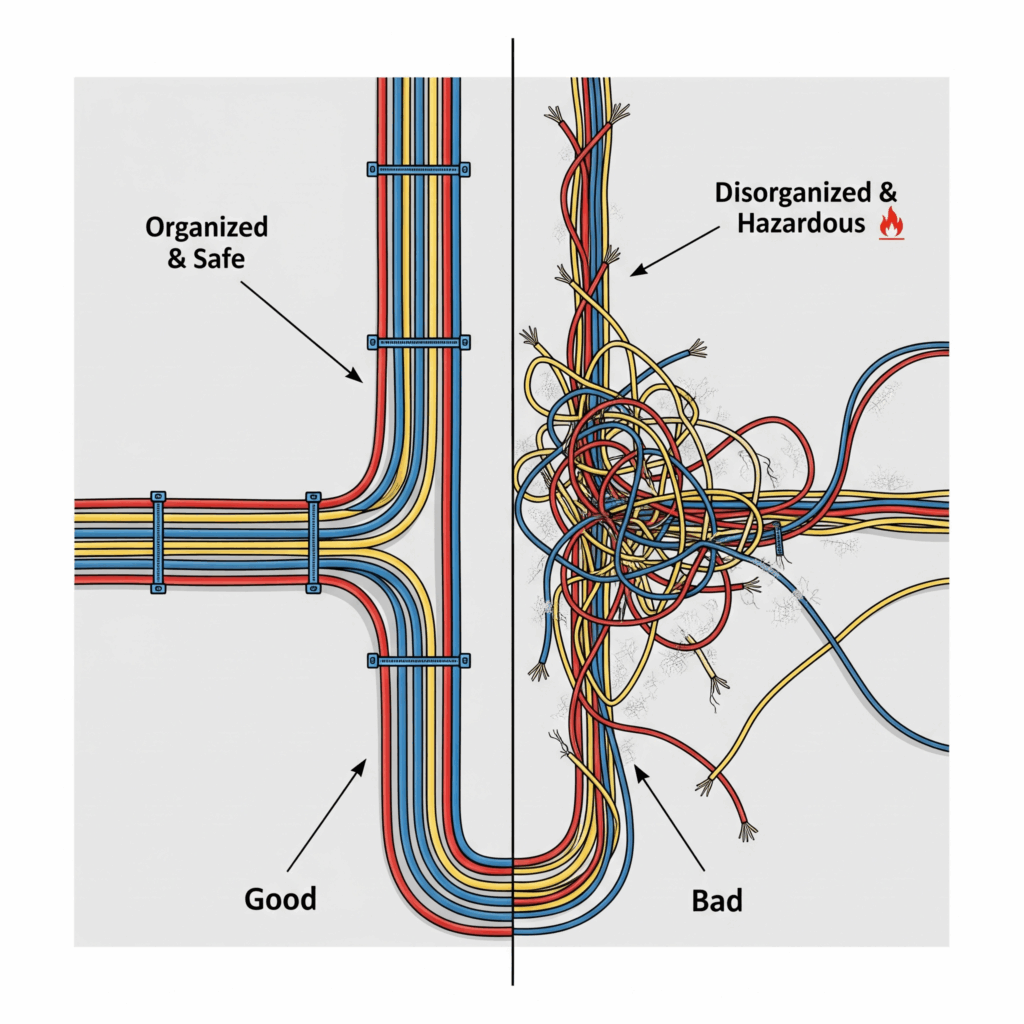

Effective cable management mitigates serious risks:

- Heat Buildup: Tightly bundled cables reduce airflow, raising temperatures and degrading insulation, potentially causing fires. This ties to wire ampacity principles: bundling or grouping conductors requires ampacity adjustment per the NEC adjustment-factor rules (see NEC 310.15(C)).

- Physical Damage: Overtightening or improper routing damages insulation, risking short circuits or ground faults (NEC 300.4).

- Serviceability: Disorganized cables complicate troubleshooting, increasing repair time and safety risks.

- Code Compliance: NEC 300.11 and 300.4 mandate proper securing and protection to ensure inspectable, safe installations.

Proper management enhances system reliability and simplifies future modifications, reflecting professional expertise.

Mastering Cable Tying for Safe Electrical Systems

Using NEC-compliant cable tying techniques prevents hazards and ensures safe electrical systems. By adhering to NFPA 70, electricians create organized, maintainable installations that meet code and protect occupants.

Professional Methods for Tying Cables

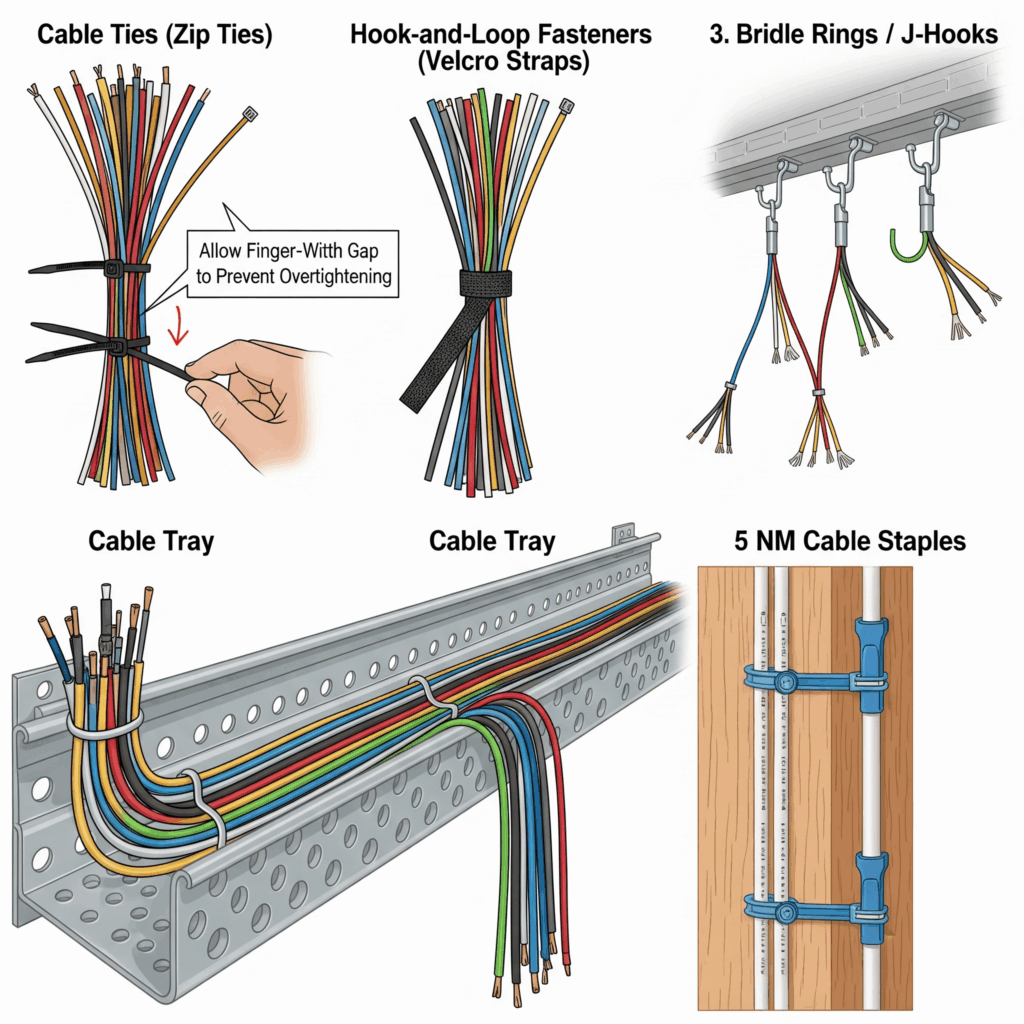

Professional cable tying requires selecting the right tools and methods for the application, per NEC 300.11 (securing/supporting) and 300.4 (protection):

Cable Ties: Secure cables without overtightening; a finger should fit under the tie to avoid insulation damage. Use flush-cut tools to prevent sharp edges (NEC 300.4). For outdoor or sun‑exposed installations, use sunlight‑resistant ties or materials listed for sunlight exposure (see NEC 300.6(C)(1)).

Hook-and-Loop Fasteners: Reusable and gentle, ideal for data or communications cables; they prevent over‑cinching and simplify modifications. Consult Article 800 and manufacturer listings for securing requirements and listed devices for communications circuits.

Bridle Rings/J-Hooks: Use listed supports such as bridle rings or J‑hooks to support cables from ceilings or beams and to help maintain proper bend radius; follow the NEC securing/support rules (see NEC 300.11) and use listed devices or cable tray systems for high‑volume commercial runs (see NEC 392).

Cable Trays: Provide structured pathways for large cable bundles, ensuring airflow and accessibility (NEC 392). Common in industrial installations.

Staples/Clips: Secure NM cables (e.g., Romex) to studs, spaced per NEC 334.30 to prevent strain.

For example, in a residential panel, neatly tied NM cables secured with staples per the NM securing/support rules help maintain accessibility to junction boxes (see NEC 334.30 and general box accessibility requirements in Article 314), while commercial data centers typically use cable trays and listed supports for organized, inspectable runs (NEC 392).

Ensuring Compliance with NEC Cable Management Standards

Adhering to NFPA 70 ensures compliant cable management, reducing risks and ensuring inspectability. Key NEC requirements include:

- Securing: Cables must be supported at the intervals specified for each wiring method — for example, NM cable support intervals are addressed in 334.30 (commonly 4.5 ft / 1.4 m), and MC cable support intervals are addressed in 330.30 (commonly 6 ft / 1.8 m).

- Bend Radius: Maintain minimum bend radii to prevent conductor damage — follow the cable‑type requirements (for example, NM — 5× diameter; MC — see Article 330 for MC specifics).

- Protection: Route cables away from sharp edges or use protective sleeves (NEC 300.4).

Safety Protocols

- De-energize: Verify circuits are off with voltage testers; use lock-out/tag-out (LOTO) procedures per OSHA and consult NFPA 70E for electrical safety and arc‑flash practices.

- Accessibility: Ensure junction boxes and receptacles are accessible per NEC requirements (see Article 314 for box and accessibility guidance).

- Clean Workspace: Organized cables reduce tripping hazards and improve safety and maintenance efficiency.

- PPE: Wear insulated gloves and safety glasses when handling cables near live systems; follow NFPA 70E PPE guidance for energized work.

Conclusion

Cable tying is a critical skill for safe, reliable electrical systems. By using proper methods, adhering to NFPA 70 (NEC 300.4, 300.11) and NFPA 70E, and prioritizing safety, electricians ensure compliant, maintainable installations that protect users and equipment.

Take the next step in your professional growth! Visit Expert CE (https://expertce.com/) for all your continuing education needs.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)