How Inverter Technology in Mini-Splits Works (VFD Theory)

How Inverter Technology in Mini-Splits Works (VFD Theory)

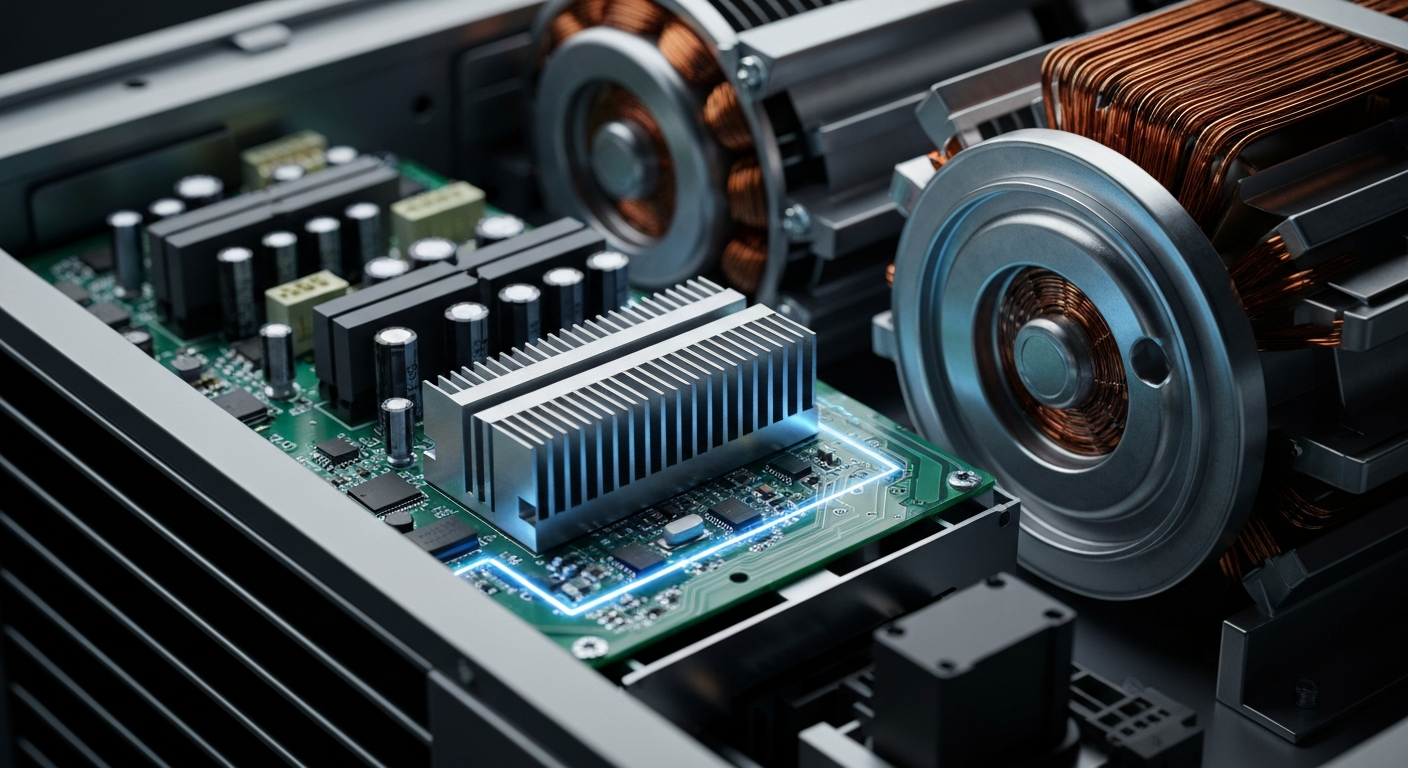

In the world of modern HVAC, inverter technology in mini-splits represents a pivotal leap in efficiency and performance. At its core, this technology uses a Variable Frequency Drive (VFD) to precisely control the compressor’s speed, moving away from the simple on/off cycles of a traditional fixed-speed AC unit. Instead of running at full power and then shutting down, a variable-speed compressor adjusts its output to exactly match the cooling or heating demand. This process begins with line voltage to DC conversion inside the VFD, which then creates a synthesized AC waveform at a variable frequency to run the compressor motor. This modulation allows the unit to maintain a consistent room temperature, dramatically reduce energy consumption, and operate much more quietly. For any master electrician or journeyman electrician, understanding VFD theory is no longer optional—it’s essential for installing and servicing these advanced systems correctly.

What is a Variable Frequency Drive (VFD) and Why Does It Matter?

The heart of any inverter-driven mini-split air conditioner is the Variable Frequency Drive (VFD). A VFD, also known as an inverter, is an electronic controller that changes the frequency and voltage of the electrical supply to a motor. In a traditional fixed-speed AC unit, the compressor motor runs at a fixed speed (typically 3,600 RPM on a 60Hz supply for a 2-pole machine) and cycles on and off to regulate temperature. This constant starting and stopping is inefficient and causes significant mechanical wear.

The VFD allows the system to operate as a variable-speed compressor. Instead of a binary on/off state, it can ramp the compressor’s speed up or down to precisely meet the cooling or heating load required at any given moment. This results in substantial energy savings—often between 20–40% depending on equipment and duty cycle—and provides far more stable and comfortable temperature control. For professionals in the electrical trade, a solid grasp of VFD principles is fundamental. To learn more about the basics, review our detailed guide on what is a VFD (Variable Frequency Drive).

The Core Process: From Single-Phase AC to Three-Phase Variable AC

Understanding how an inverter works requires looking at the step-by-step power conversion process. While the unit plugs into a standard single-phase residential power source, the compressor itself is a highly efficient Three-Phase Compressor Motor. The VFD’s job is to perform this conversion.

-

The Bridge Rectifier: Line Voltage to DC Conversion

The first stage inside the VFD is the Bridge Rectifier. This component takes the incoming single-phase alternating current (AC) from the building’s wiring and converts it into direct current (DC). This process is known as line voltage to DC conversion. The resulting raw DC power is then smoothed out by a series of capacitors, creating a stable high-voltage potential known as the DC Bus Voltage. This steady DC voltage is the power source for the next stage. -

The Inverter Stage: PWM and the IGBT

This is where the “inverter” part of the technology truly happens. The stable DC bus voltage is fed into a set of sophisticated electronic switches called Insulated Gate Bipolar Transistors (IGBTs). These IGBTs are the workhorses of the VFD, capable of switching on and off thousands of times per second. By controlling the timing and duration of these switches using a method called Pulse Width Modulation (PWM), the VFD can chop up the DC voltage and reassemble it into a simulated three-phase AC waveform. The width of the pulses is “modulated” to create a smooth, variable-frequency sine wave. -

Driving the Three-Phase Compressor Motor

The simulated three-phase AC output from the IGBTs is then sent to the variable-speed compressor. The frequency of this synthesized AC power determines the motor’s speed (RPM). A lower frequency slows the compressor down for low-load conditions, while a higher frequency speeds it up for rapid cooling or heating. This Single-Phase to Three-Phase Conversion is what allows for the incredible efficiency and precise control that define inverter systems.

Electrical Considerations for the Journeyman and Master Electrician

Installing an inverter-driven mini-split air conditioner is more complex than a standard appliance. For a journeyman electrician or master electrician, several key electrical factors must be considered to ensure a safe and compliant installation.

First, NEC requires that branch-circuit conductors be properly sized for the equipment and that overcurrent protection and disconnecting means comply with Article 440; manufacturers commonly specify a dedicated branch circuit and the Minimum Circuit Ampacity (MCA) and Maximum Overcurrent Protection (MOP) ratings that must be followed. The wire gauge and breaker size must be selected based on the manufacturer’s specifications, paying close attention to the MCA and MOP values. For more details on these critical ratings, you can read our article on MCA and MOP HVAC ratings explained.

The Full Load Amps (FLA) on an inverter unit can be misleading. Unlike a conventional motor with a high locked-rotor amperage (LRA), a VFD-driven motor is typically soft-started by the drive so inrush/starting current is much lower than a direct-on-line start; however installers must still size conductors and protection using the manufacturer’s MCA and MOP values and consider harmonics and drive characteristics. Another factor to consider is Total Harmonic Distortion (THD). The high-frequency switching of the IGBTs can introduce harmonic currents back onto the electrical system, which can interfere with other sensitive electronics. Modern inverters are designed to minimize THD, but it remains an important consideration in commercial or industrial settings.

Proper wiring is critical. For guidance on connecting the indoor and outdoor units and running the necessary power lines, refer to our installation guides on how to install mini-split wiring and how to wire a ductless mini-split.

Communicating Systems, Sensors, and Diagnostics

Modern inverter mini-splits are sophisticated Communicating Systems. The indoor unit, outdoor unit, and thermostat are in constant digital communication, sharing data to optimize performance. This communication typically occurs over a dedicated, low-voltage wire in the bundle connecting the units.

This constant feedback loop is made possible by a network of Thermistors and Sensors. These devices monitor refrigerant pressures, coil temperatures, and ambient air temperatures, feeding data back to the main control board. The system uses this information to make micro-adjustments to the compressor speed and electronic expansion valve, maintaining peak efficiency.

For technicians, this complexity introduces new challenges. Inverter Board Diagnostics requires more than a simple volt-ohm meter. It often involves checking DC voltages on the board, testing the IGBTs with a meter set to diode check, and verifying communication signals. Many manufacturers now offer specialized diagnostic tools to interface with the system and read fault codes, which is becoming a necessary part of modern electrician training.

Key Takeaways for Electrical Professionals

- VFD is the Core: Inverter technology is fundamentally VFD technology applied to an HVAC compressor.

- Power Conversion is Key: The system converts incoming single-phase AC to DC, then inverts it back to a variable-frequency three-phase AC to control the compressor.

- Efficiency is the Primary Benefit: By matching motor speed to the real-time load, inverter units drastically cut energy use compared to fixed-speed systems.

- Code Compliance is Crucial: A Dedicated Circuit, proper wire sizing based on MCA/MOP, and an outdoor disconnect are non-negotiable for a safe installation. NEC Article 440 includes requirements for branch-circuit protection, disconnecting means, and nameplate information that installers must follow.

- Diagnostics are Different: Troubleshooting requires an understanding of the Inverter Board Diagnostics, including checking DC bus voltage and testing IGBTs.

The rapid adoption of inverter technology means that staying current is more important than ever. Mastery of these systems is a valuable skill for any electrician. Stay ahead of HVAC technology. See our courses on VFDs and modern systems.

Frequently Asked Questions

- What is the main difference between a standard traditional fixed-speed AC unit and inverter technology mini-splits?

- A standard fixed-speed AC unit uses a fixed-speed compressor that cycles on and off, causing temperature swings and high energy consumption during startup. An inverter technology mini-split uses a Variable Frequency Drive (VFD) to run a variable-speed compressor, continuously adjusting its speed to match the cooling load, resulting in better efficiency and more stable temperatures.

- How does a Variable Frequency Drive (VFD) enable Single-Phase to Three-Phase Conversion?

- A VFD takes standard single-phase AC power and first converts it to DC using a Bridge Rectifier. Then, using Pulse Width Modulation (PWM) and Insulated Gate Bipolar Transistors (IGBTs), it creates a new, simulated three-phase AC output. This allows a highly efficient Three-Phase Compressor Motor to be used in a residential application with single-phase power.

- Why is a Dedicated Circuit important for an inverter mini-split?

- A Dedicated Circuit is a critical safety and performance measure. NEC requires branch-circuits to be sized and protected for the equipment; manufacturers often require a dedicated circuit and publish MCA and MOP values to guide conductor sizing and overcurrent protection. Isolating the mini-split from other household loads prevents voltage drops that could damage sensitive inverter electronics.

- What role do Thermistors and Sensors play in an inverter system?

- Thermistors and Sensors are critical components of the system’s feedback loop. They constantly monitor temperatures and pressures throughout the refrigerant circuit and feed this data to the main control board. The board uses this information to make precise adjustments to the compressor speed, optimizing efficiency and performance.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)