How Autotransformers Work: Applications and Theory

How Autotransformers Work: Applications and Theory

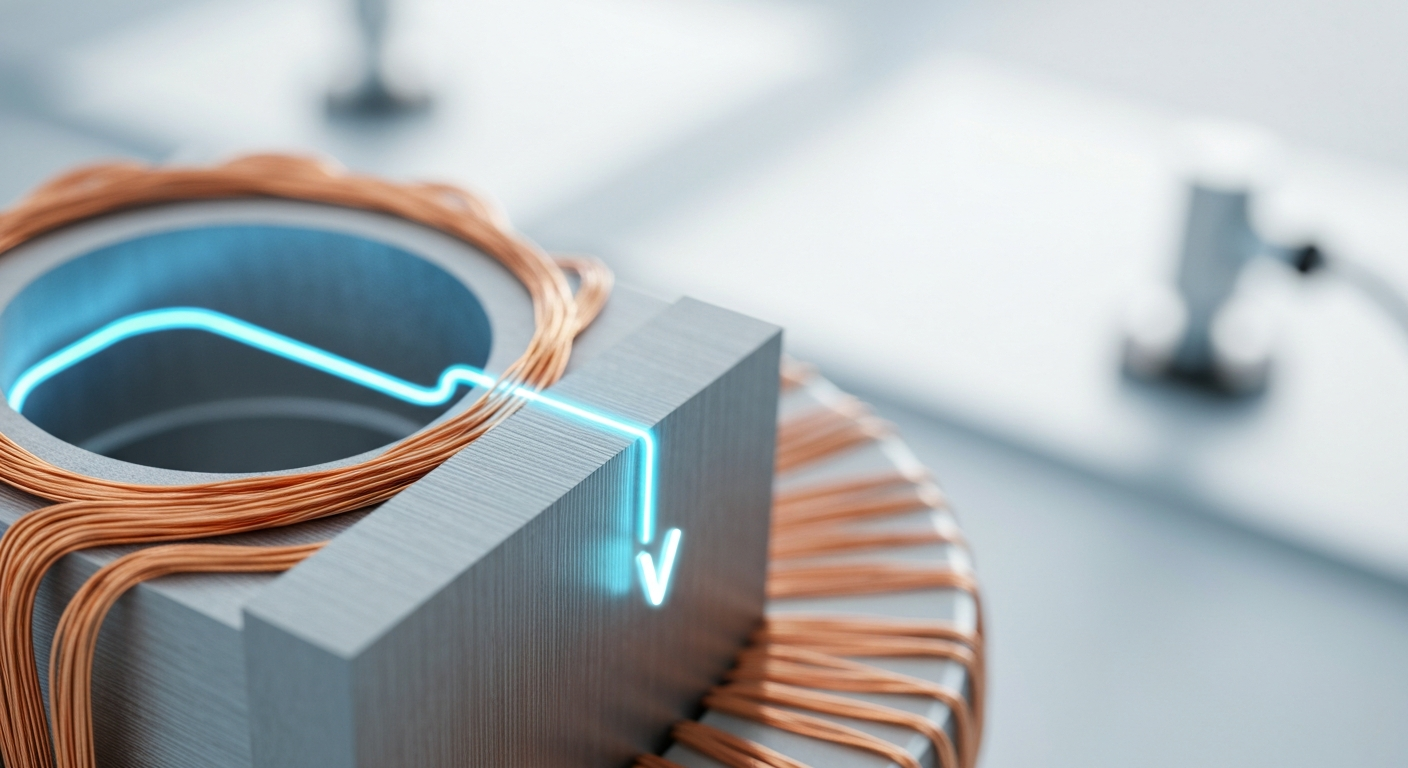

An autotransformer is a unique type of electrical transformer distinguished by its use of a single, continuous winding that acts as both the primary and secondary coil. Unlike conventional two-winding transformers, this single-winding transformer design allows a portion of the electrical energy to flow conductively from the input to the output. The core principle of how autotransformers work relies on tapping this common winding at different points to either step-up or step-down the voltage. This efficient design makes them smaller, lighter, and more economical than isolation transformers for applications where electrical isolation is not required. The fundamental autotransformer theory centers on sharing a winding, enabling applications like voltage regulation, reduced voltage motor starting, and interconnecting power systems of different voltage levels. This guide breaks down their operation, applications, and key differences from standard transformers for the professional electrician.

Autotransformer Theory: The Single Common Winding Design

To understand how an autotransformer functions, it’s essential to contrast it with a conventional two-winding electrical transformer. A standard transformer uses two physically separate and electrically isolated coils wrapped around a magnetic core. The energy transfer happens purely through magnetic induction. This provides galvanic isolation, meaning there is no direct electrical path between the high-voltage and low-voltage sides.

An autotransformer, however, uses only one common winding, where a portion of the coil is shared by both the primary (input) and secondary (output) circuits. In this design, part of the winding is connected in series with the load, which creates a direct electrical connection between the input and output sides.

The voltage change is achieved by selecting a connection point, or “tap,” along the winding. The transformation ratio—the relationship between the input and output voltage—is determined by the ratio of the number of turns in the tapped section to the total number of turns in the entire winding. Because a portion of the power is transferred conductively through the common winding while the remainder is transferred magnetically, an autotransformer can be smaller and more efficient than a two-winding transformer for the same total kVA when the voltage ratio is near unity.

How Autotransformers Work: Step-Up vs. Step-Down Operation

The versatility of the autotransformer comes from its ability to function in either step-up or step-down mode by simply changing the input and output connections on its tapped winding.

Step-Down Autotransformer

In a step-down autotransformer configuration, the full winding is connected across the high-voltage source. The output is then taken from a tap point and the common terminal. For example, to step down 480 V to 240 V, the entire winding would be connected across the 480 V source and the load taken from an appropriate tap that provides the desired turns ratio (in a simple evenly wound design a midpoint tap would yield roughly half voltage). The exact tap location must be based on the transformer turns ratio and the manufacturer’s design.

Step-Up Autotransformer

For a step-up autotransformer, the configuration is reversed. The lower input voltage is applied across only a portion of the winding. The output, a higher voltage, is then taken from across the full winding. This setup effectively adds the voltage induced in the series portion of the winding to the source voltage to produce the higher output. Autotransformers are used in high-power transmission and substation applications to interconnect nearby voltage levels (for example, boosting or stepping between transmission classes), taking advantage of their high capacity and relative economy compared with two-winding transformers where isolation is not required.

Key Differences: Autotransformer vs Isolation Transformer

For a journeyman electrician or master electrician, choosing the right component is critical. The primary distinction between an autotransformer and an isolation transformer is the lack of electrical isolation in the former.

- Electrical Isolation: An autotransformer does NOT provide electrical isolation. The primary and secondary circuits are physically connected. An isolation transformer provides complete galvanic separation, which is critical for safety in many electronic and medical applications.

- Size and Weight: For the same kVA rating (especially when the voltage ratio is close to 1), an autotransformer is significantly smaller, lighter, and uses less copper and iron.

- Efficiency and Regulation: Autotransformers are generally more efficient because only a fraction of the power undergoes magnetic transformation, reducing losses. This also results in better voltage regulation in many cases.

- Cost: The reduced material requirements make autotransformers more cost-effective than their two-winding counterparts.

Practical Applications for the Professional Electrician

Autotransformers are found in numerous industrial and commercial applications where their unique properties offer distinct advantages. Understanding these uses is key for any electrician performing installations or maintenance.

Voltage Regulation and Correction

One of the most common uses is to correct for voltage drop over long conductor runs or to stabilize fluctuating utility power. Configured as a buck-boost transformer, an autotransformer can slightly increase (boost) or decrease (buck) a line voltage to bring it within an acceptable range. This is essential for protecting sensitive equipment and ensuring compliance with standards mentioned in the NEC regarding acceptable voltage drop.

Reduced Voltage Starting for Induction Motors

Large induction motors draw a very high inrush current upon starting, which can cause significant voltage dips in the electrical system. Using an autotransformer for reduced voltage starting is a common and effective method to mitigate this. The motor is initially connected to the taps of the autotransformer, which supply a reduced voltage (e.g., 50%, 65%, or 80% of the line voltage). This limits the starting current. Once the motor reaches a certain speed, it is disconnected from the autotransformer and connected directly to the full line voltage. This application is a cornerstone of industrial motor control and a key topic in advanced online electrical courses.

Advance your knowledge of specialized electrical components. View our courses.

Power Transmission and Interconnection

In utility power systems, large autotransformers are used to interconnect grids operating at different voltage levels, such as connecting nearby transmission voltages. Their high efficiency and lower cost make them ideal for many high-power applications where electrical isolation between the two voltages is not required. Understanding the different voltage classes is useful for these applications; see resources on high, medium, and low voltage definitions. They are also integral components in complex power systems, including those involving 480V 3-phase power and other 3-phase transformer configurations.

Variable Transformers (Variac)

A Variac is a specific type of autotransformer with a continuously adjustable tap. Instead of fixed taps, a sliding carbon brush moves across the winding, allowing for smooth voltage adjustment from 0% up to the input voltage, and in some designs slightly above the input. These are widely used in testing labs, repair shops, and experimental setups where precise voltage control is necessary.

Sizing and NEC Code Considerations: A Step-by-Step Overview

Properly sizing and protecting an autotransformer requires careful calculation and adherence to the NEC (NFPA 70). While detailed engineering is complex, every electrician should understand the basic process.

- Determine System Parameters: Identify the input voltage (VH), output voltage (VL), and the required load in kVA.

- Calculate the Transformation Ratio: The ratio is simply VH / VL. A ratio close to 1:1 yields the greatest size and cost advantages for an autotransformer.

- Calculate the Transformed Power: The key to sizing is finding the portion of power that is magnetically transformed. For a step-down autotransformer, a common formula is: kVA_transformed = kVA_load * ((VH – VL) / VH), where VH is the high voltage and VL is the low voltage. That transformed kVA determines the core and copper sizing for the autotransformer.»

- Select the Autotransformer: The physical size of the autotransformer corresponds to the kVA_transformed value, not necessarily the full load kVA. This is why they are usually smaller than isolation transformers for comparable total kVA when the voltage ratio is near unity.

- Apply NEC Article 450 and Article 250: Refer to the National Electrical Code, specifically Article 450 for transformer overcurrent protection and autotransformer provisions and Article 250 for grounding and bonding. Article 450 contains autotransformer-specific rules (see the subsections dealing with autotransformer protection and grounding), but the exact grounding and bonding requirements depend on the intended application and whether the device establishes a neutral point; when in doubt, follow Article 250 and the transformer manufacturer’s instructions.

Advantages and Critical Safety Considerations

While efficient and economical, the autotransformer’s design brings a unique set of pros and cons that every professional must weigh.

- Advantages: Higher efficiency, smaller physical size, lower weight, reduced cost, and better voltage regulation compared to a two-winding transformer of the same rating when the voltage ratio is close to unity.

- Disadvantages & Safety Risks: The most significant risk is the lack of galvanic isolation. A failure in the common winding, such as an open circuit in the shared portion, can expose the low-voltage circuit to the full high-voltage input. This makes them unsuitable for applications where electrical separation (isolation) is a safety requirement. Grounding, bonding, and overcurrent protection requirements vary with the application; Article 450 of the NEC and Article 250 address these subjects and must be consulted to mitigate hazards in each installation.

Frequently Asked Questions

- What is the main difference in an autotransformer vs isolation transformer?

- The primary difference is that an autotransformer uses a single, shared winding, while an isolation transformer has two physically separate windings. This means an autotransformer does not provide electrical (galvanic) isolation, but an isolation transformer does.

- Why don’t autotransformers provide galvanic isolation?

- They lack galvanic isolation because the primary and secondary circuits share a physical part of the same copper winding. There is a direct electrical connection between the input and output, which is fundamentally different from the magnetically-coupled but electrically separate coils of an isolation transformer.

- When is an autotransformer used for induction motor starting?

- An autotransformer is used for reduced voltage starting of large induction motors to limit the high inrush current drawn during startup. By providing a lower, tapped voltage initially, it lessens the impact on the electrical system. It’s a common method for motors where a soft start is needed to prevent voltage sag or mechanical stress.

- How does a Variac work?

- A Variac is a variable autotransformer with a sliding tap. A movable carbon brush acts as the tap, sweeping across an exposed part of the single winding to provide smooth, continuous voltage control from zero up to the input voltage, and in some designs slightly higher.

- Are there specific NEC code rules for autotransformers?

- Yes. NEC Article 450 covers transformers, including autotransformers, and lays out requirements for overcurrent protection and other installation considerations. Grounding of autotransformers is application-specific and frequently requires coordination with Article 250. For additional application context, refer to NEC guidance on voltage drop and the manufacturer’s instructions. For additional guidance, refer to the NEC and Article 250.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)