Conduit vs. Wireways vs. Gutters: An NEC Comparison Guide

Understanding the Basics: Conduit Meaning and Application

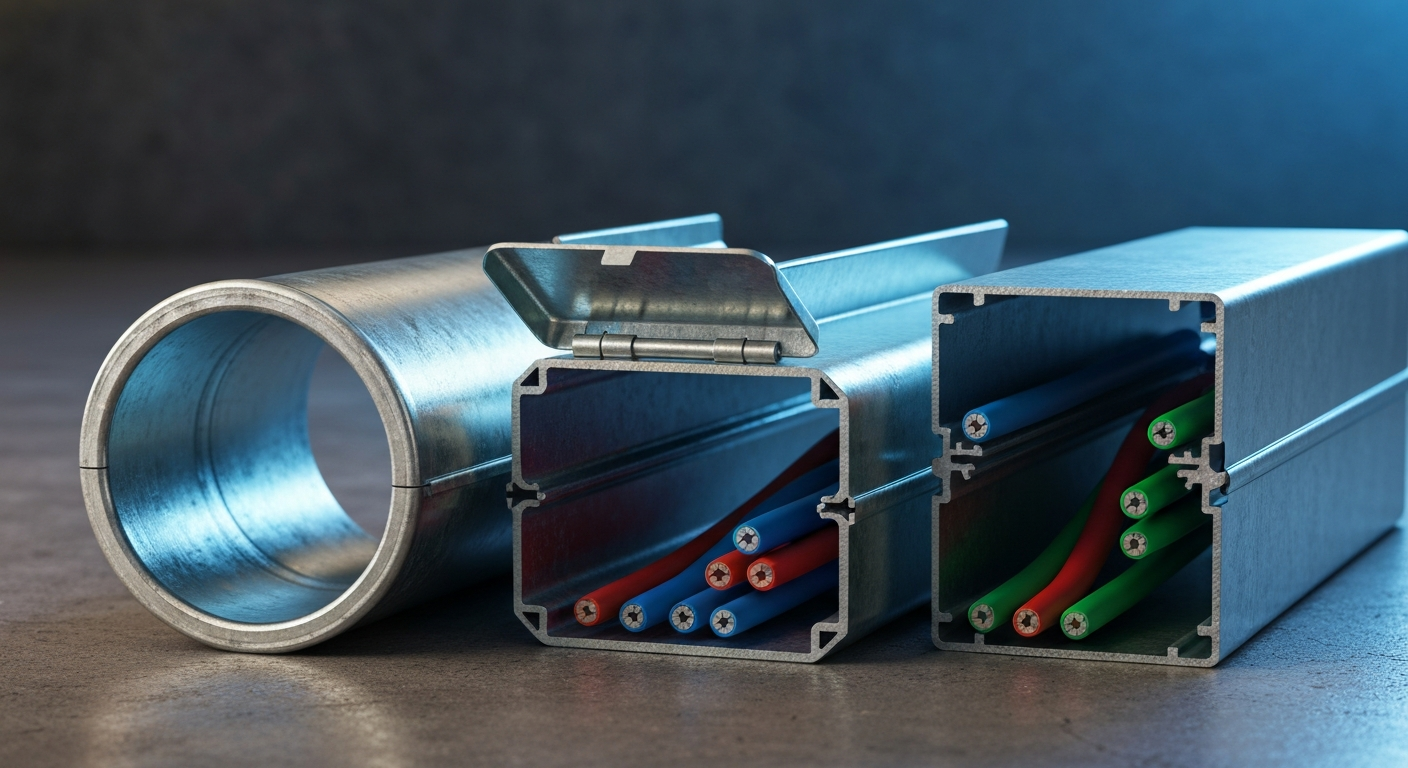

For most electricians, conduit is the backbone of electrical installations. It is one of the most fundamental cable protection systems, designed to protect conductors from impact, moisture, and chemical vapors. The National Electrical Code (NEC) provides extensive rules for various conduit types, from Rigid Metal Conduit (RMC) and Electrical Metallic Tubing (EMT) to PVC. For instance, a common heavy-duty option is rigid metal conduit (RMC), often galvanized (sometimes called RGS for rigid galvanized steel), known for its superior strength in demanding environments.

A key aspect of working with conduit is calculating the maximum number of conductors it can safely hold. This calculation, often referred to as EMT fill capacity for that specific raceway type, is detailed in NEC Chapter 9. Unlike the flat 20% rule for wireways, conduit fill percentages vary based on the number of conductors (for circular conductors the typical allowance is about 53% for one conductor, 31% for two, and 40% for three or more), and the type of conduit can have specific installation requirements; for example, PVC installed in certain underground or concrete-encased applications has additional installation provisions. See practical guidance like 2023 NEC rules for PVC conduit use in concrete for more context. Furthermore, proper installation techniques, like knowing how expansion fittings protect underground conduits, are critical for a durable and code-compliant system.

A Deep Dive into Wireways: NEC Article 376

When an installation involves numerous conductors that may need to be accessed or modified later, wireways become an excellent choice. Governed by NEC Article 376 (for metal wireways) and Article 378 (for nonmetallic wireways), these raceways are essentially troughs with covers. The discussion of metal trough vs conduit often highlights the primary advantage of wireways: accessibility. Instead of pulling conductors through a closed pipe, electricians can simply lay them into the trough, making it an ideal choice for complex commercial wiring methods and industrial raceway solutions.

However, this accessibility comes with specific rules. The most significant is the conductor fill limit: the sum of the cross-sectional areas of all contained conductors cannot exceed 20% of the wireway’s interior cross-sectional area. Additionally, electricians must apply wireway derating factors for ampacity when more than 30 current-carrying conductors are present at any cross-section, a crucial detail that impacts circuit design.

The Role of Auxiliary Gutters: NEC Article 366

An electrical gutter, more formally known as an auxiliary gutter, can look very similar to a wireway but serves a different function as defined by NEC Article 366. The key distinction is that auxiliary gutters are used to supplement wiring space at meter centers, distribution centers, switchgear, and similar locations. They are not intended to be used as a general raceway between distant points.

The auxiliary gutter requirements include a critical rule: the total area of conductors, splices, and taps within the gutter cannot exceed 75% of its cross-sectional area, and the conductor fill (excluding splices and taps) is limited to 20%, similar to wireways. Their use is often tied to enclosing busbars or wiring conductors between enclosures, and it’s essential to use UL listed electrical gutters to comply with safety standards. The concept of managing space and connections within these enclosures shares principles with other calculations, such as how to calculate junction box sizes.

Conductor Fill Calculations: A Comparative Raceway Sizing Guide

Understanding the different fill rules is at the heart of the conduit vs wireways decision. Miscalculating can lead to code violations and dangerous overheating. This raceway sizing guide highlights the core differences.

How to Perform Basic Conductor Fill Calculations for Wireways (NEC 376.22)

- Determine the Wireway’s Internal Area: Calculate the interior cross-sectional area of the wireway in square inches (e.g., a 4″ x 4″ wireway has an internal area of 16 sq. in.).

- Calculate the 20% Conductor Fill Limit: Multiply the wireway’s internal area by 0.20. For a 16 sq. in. wireway, the maximum area for conductors is 3.2 sq. in. (16 x 0.20).

- Calculate Total Conductor Area: Using NEC Chapter 9 tables, find the approximate area in square inches for each conductor you plan to install. Sum these areas together.

- Verify Compliance: Ensure the total conductor area from Step 3 does not exceed the 20% limit calculated in Step 2.

- Apply Derating Factors: Per NEC 376.22(B), if you have more than 30 current-carrying conductors at any cross-section, you must apply the ampacity adjustment factors found in 310.15(C)(1).

This strict 20% fill for conductors in wireways and gutters contrasts with conduit, which allows higher fill percentages (for circular conductors, about 53% for one conductor, 31% for two, and 40% for three or more). Note that conduit does not “prohibit” splices and taps outright, but it requires splices, taps and terminations to be made in accessible boxes, conduit bodies, or other permitted enclosures; splicing “buried” within a continuous conduit run without an accessible enclosure is not permitted.

Practical Considerations: Installation, Costs, and Pull Boxes

Beyond NEC rules, the choice between these systems involves practical trade-offs. Feeling confident in these calculations and applications is key. Master conductor protection with our NEC 2023 code change courses.

- Accessibility: Wireways and gutters offer superior access for future work. Adding a circuit to a wireway is far simpler than pulling a new wire through a filled conduit.

- Protection: Conduit, especially rigid metal conduit (RMC), provides significantly better physical protection against impact than most wireway systems.

- Splices and Taps: Permitted in wireways and auxiliary gutters under specific NEC rules (conductors including splices and taps shall not fill the wireway or gutter to more than 75% of its area at that point). In conduit, splices and taps must be made only in accessible enclosures (boxes, conduit bodies, etc.); they are not allowed to be concealed within a conduit run without such an accessible enclosure.

- Raceway Installation Costs: While conduit material is often cheaper per foot, the labor for pulling wires, especially on complex runs requiring multiple electrical pull boxes, can be much higher. Wireways may have higher upfront material costs but can drastically reduce labor for both initial installation and future modifications.

Primary Sources for Electrical Raceway Standards

As professionals, we must ground our work in official standards. Always refer to the latest editions for final authority.

- NFPA 70, National Electrical Code (NEC)

- Underwriters Laboratories (UL) for listed product information

Frequently Asked Questions (FAQ)

- What is the main difference in conductor fill calculations for conduit vs wireways?

- The main difference is the percentage and basis of the calculation. For conductor fill calculations in conduit (with 3+ conductors), you can typically use about 40% of the cross-sectional area for circular conductors. In contrast, wireways are limited to 20% fill for conductors. Additionally, wireways have separate rules allowing splices and taps up to a 75% fill at any point, and specific wireway derating factors must be applied when exceeding 30 current-carrying conductors.

- When should I choose an electrical gutter over a wireway?

- You should use an electrical gutter (auxiliary gutter) specifically to supplement wiring space for short distances directly at equipment like meter centers, panelboards, or switchgear, as governed by NEC Article 366. Choose wireways (per NEC Article 376) when you need to route groups of conductors and cables over distances between points, where easy access for future work is a priority.

- Are hinged-cover wireways a good choice for commercial wiring methods?

- Absolutely. Hinged-cover wireways are an excellent component of modern commercial wiring methods and industrial raceway solutions. Their primary benefit is accessibility, which dramatically reduces labor costs for future maintenance, troubleshooting, and adding new circuits. This makes them one of the most flexible cable protection systems available for environments where changes are anticipated.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)