Calculating the Area of a Circle for Conduit Fill Math

Mastering Conduit Fill Math: A Guide to Calculating Circle Area

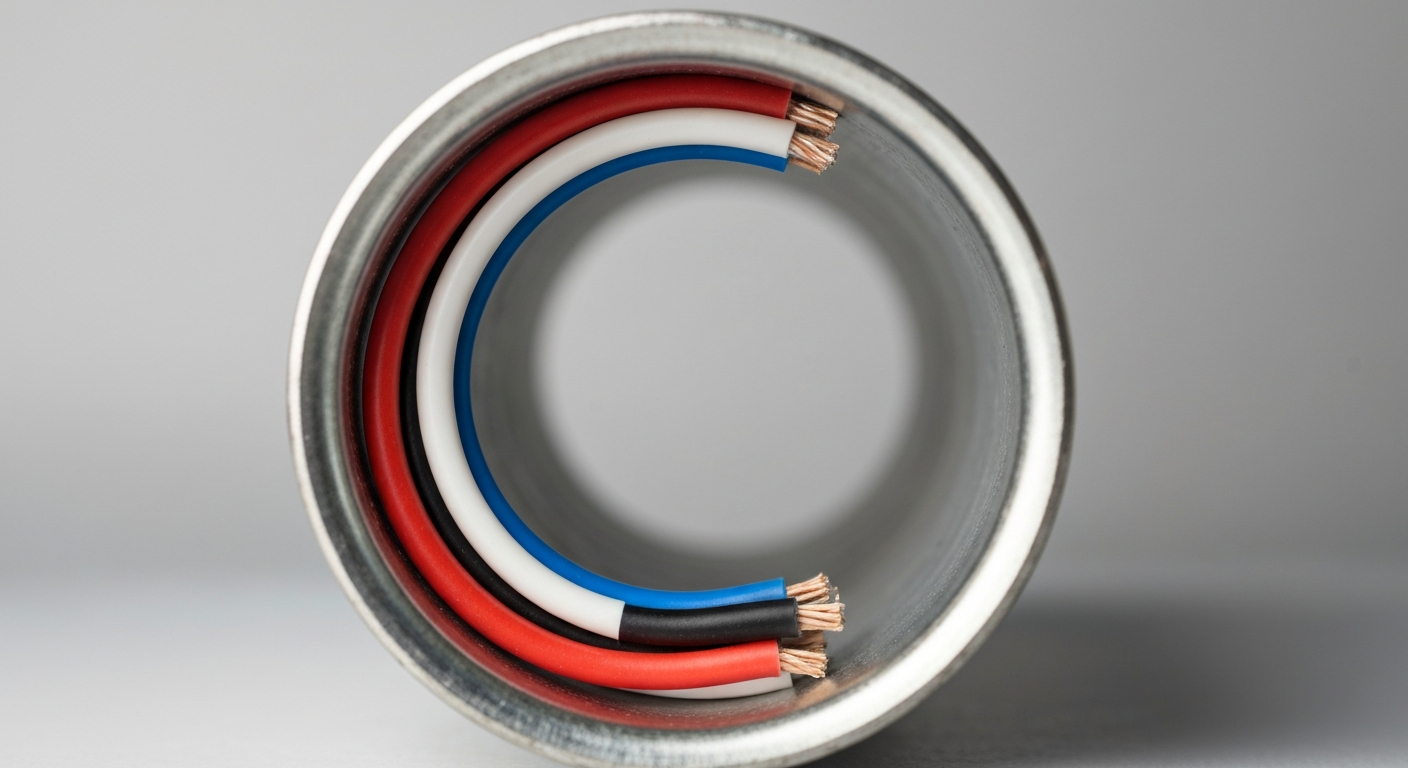

Properly executing conduit fill math is a non-negotiable skill for any licensed electrician, forming the backbone of safe and compliant electrical installations. The core of these raceway calculations involves determining if the total cross-sectional area of all conductors fits within the allowable fill of a conduit without exceeding the maximum conduit fill percentage. The fundamental step is calculating the area of each conductor, which relies on the classic formula for a circle’s area: Area = πr². While a conduit fill calculator offers a quick solution, understanding the manual process outlined in the National Electrical Code (NEC) is essential for passing exams and troubleshooting in the field. Mastering this calculation ensures you adhere to NEC Chapter 9, prevent wire damage, and avoid dangerous heat buildup, a critical piece of knowledge for any journeyman electrician or master electrician.

Why Accurate Area Calculation is Critical for Conduit Fill Math

At first glance, conduit fill math might seem like a simple exercise in fitting wires into a pipe. However, these calculations are a cornerstone of electrical safety, mandated by the National Electrical Code (NEC) to prevent hazardous conditions. When conductors are packed too tightly, heat cannot dissipate effectively, which can degrade and melt insulation, leading to short circuits and potential fires. The nec code book establishes limits on conductor fill to mitigate these risks.

The most common rule, found in the tables of NEC Chapter 9, states that for three or more conductors the total area of the wires is limited by the allowable conduit fill percentage shown for that raceway (commonly 40% for many raceway types when more than two conductors are present). This conduit fill percentage provides adequate space for heat dissipation and allows conductors to be pulled without damaging their insulation. Exceeding the limit not only violates code but significantly increases the jam probability during pulls, where conductors wedge together and complicate installation. For any professional, from a newly licensed journeyman electrician to a seasoned master electrician, precise raceway calculations are a mark of quality and a commitment to safety.

The Fundamental Formula: Calculating Cross-Sectional Area

The basis of all conductor fill calculations is the geometric formula for the area of a circle. Since wires are circular, their area determines how much space they occupy inside a conduit.

The primary formula is:

Area = π × r²

Where:

- π (Pi) is a constant, approximately 3.14159.

- r is the radius of the circle (half of its diameter).

While this formula is accurate, electricians often work with diameters, which are easier to measure and are listed in the NEC tables. A more practical variation of the formula uses diameter (d):

Area = (π/4) × d² or Area ≈ 0.7854 × d²

The value 0.7854 is a handy shortcut that every apprentice should memorize as part of their electrician training. However, for official calculations, it’s best to rely on the pre-calculated areas provided in the NEC tables to ensure maximum accuracy, especially since these tables account for insulation thickness.

Step-by-Step Guide to Calculating Total Conductor Area

Manually performing conduit fill math is a required skill for licensing exams and a great way to double-check the results from a conduit fill calculator. Follow these steps using your nec code book.

- Identify Your Conductors and Raceway: Determine the specifics of your installation. This includes the raceway type (e.g., EMT conduit, rigid metal conduit (RMC)), the wire gauge (AWG) of your conductors, and the conductor insulation type (e.g., THHN, XHHW). The insulation type is critical, as it directly impacts the overall diameter.

- Find Each Conductor’s Cross-Sectional Area: Turn to NEC Chapter 9 tables (the table listing conductor areas for insulated conductors). These chapter tables provide the area in square inches for various conductor types and sizes. Using these tabulated areas is more accurate than calculating from a nominal diameter because the tables reflect insulation and construction differences.

- Calculate the Total Conductor Area: Add the cross-sectional areas of all conductors you plan to install in the raceway. If you have multiple conductors of the same size, multiply the area of one by the total quantity. For example, six #12 THHN conductors (each with an area listed in Chapter 9) would have a total area equal to 6 × (area of one #12 THHN).

- Determine the Raceway’s Allowable Fill Area: Refer to NEC Chapter 9 for the dimensions of your specific conduit type and the allowable fill percentage for your conductor count. Find your trade size and apply the appropriate allowable fill percentage (for more than two conductors this is commonly the column associated with the >2-conductor allowable fill percentage). Multiply the conduit internal cross-sectional area by that percentage to get the maximum allowable conductor area.

- Compare and Verify: Ensure the total conductor area from Step 3 is less than or equal to the allowable fill area from Step 4. If your conductor area is greater, you must select a larger conduit size or reduce conductor count.

Beyond Circles: Special Considerations in Raceway Calculations

While most conductors are round, real-world raceway calculations can involve other factors.

- Circular Mil Area vs. Cross-Sectional Area: The NEC provides conductor area values in square inches (for conduit fill) and also uses circular mil area for conductor ampacity and engineering calculations. It’s vital not to confuse these: for conduit fill math, always use the area in square inches from the Chapter 9 area tables.

- Nonround and Multi-conductor Cables: Chapter 9 includes notes that describe how to account for noncircular profiles. When a cable presents an elliptical or flattened profile, follow the Chapter 9 guidance and use the dimension that ensures you account for the largest space the cable will occupy in the raceway.

- Pulling and Practical Fit: The NEC does not prescribe a specific “jam ratio” for conduit-to-conductor diameters. If conductors are very close to the maximum allowed fill or the fit appears tight, choose a larger conduit or follow conductor and manufacturer pull guidance to reduce the risk of snags or insulation damage. Good field practice and the Chapter 9 limits together minimize pull and heat issues.

Understanding these nuances is essential for any project, from standard residential wiring to complex installations in wireways and gutters.

Using Tools: Conduit Fill Charts and Calculators

While manual calculations are essential for electrician training, professionals in the field rely on tools to improve efficiency and accuracy. A conduit fill chart provides a quick-reference grid showing the maximum number of same-sized conductors allowed in a specific conduit. These are excellent for common scenarios.

For more complex jobs with mixed conductor sizes, a digital conduit fill calculator is invaluable. These tools perform the same math—summing the areas from the Chapter 9 conductor-area table and comparing them to the allowable fill percentage from the Chapter 9 conduit table—but do so instantly, eliminating the chance of human error. While calculators are helpful, mastering the manual raceway calculations is non-negotiable for passing your licensing exam. Prepare for code-based calculations with NEC study resources.

Key Takeaways for NEC-Compliant Conduit Fill

- Always reference the official nec code book, specifically NEC Chapter 9. The Chapter 9 tables define the allowable fill percentages and provide conduit dimensions and conductor areas.

- The commonly used conduit fill percentage for installations with more than two conductors is shown in Chapter 9 (commonly 40% for the >2-conductor case for many raceway types), but always check the specific table for your raceway type and trade size.

- Clearly distinguish between cross-sectional area in square inches (for conductor fill) and circular mil area (for voltage drop and ampacity).

- The conductor insulation type is a critical variable. Different insulations (e.g., THHN vs. XHHW) have different thicknesses, which changes the overall diameter and area; that is why Chapter 9 lists insulated conductor areas rather than relying on bare conductor diameters.

- Code compliance extends beyond conduits to other enclosures. Similar area-based rules and guidance apply when you determine allowed fill for boxes, gutters, and other raceway assemblies—again, see Chapter 9 and the applicable articles for the enclosure type.

Primary Sources

- NFPA 70, National Electrical Code (NEC), 2023 Edition

Frequently Asked Questions

What is the fastest way to do conduit fill math in the field?

The fastest and most reliable method for complex scenarios is using a digital conduit fill calculator on a smartphone or tablet. For simple runs with same-sized wires, a printed conduit fill chart is extremely fast. Both tools rely on the same data from the NEC tables.

Where in the National Electrical Code do I find information on conductor fill?

All primary information for conductor fill is located in NEC Chapter 9. The chapter tables provide allowable percent fill and dimensions for raceways and tabulated areas for insulated conductors.

Do derating factors affect my conduit fill percentage?

Derating factors (ampacity adjustments) and conduit fill percentage are separate but related calculations. Conduit fill is about physical space, while derating (ampacity adjustment) is about heat in bundled current-carrying conductors (see NEC articles on conductor ampacity). You must perform both calculations: a high conductor count that is acceptable for fill (under the Chapter 9 allowable percentage) might still require you to derate conductor ampacity, potentially forcing you to use a larger wire gauge, which in turn affects your fill calculation.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)