Top 5 Grounding and Bonding Mistakes to Avoid on the Job

From residential service changes to complex commercial installations, avoiding common grounding and bonding mistakes is crucial. Let’s break down the top five errors electricians encounter in the field and how to ensure your installations are safe, compliant, and built to last.

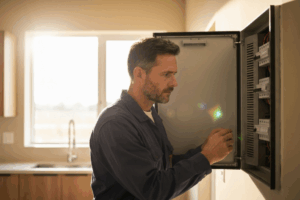

1. Improper Neutral-to-Ground Bonding in Subpanels

This is arguably the most common and dangerous of all grounding and bonding mistakes. In a service entrance panel, the main bonding jumper creates the critical neutral-to-ground bond. This is the only place in a standard system where this connection should occur. Its job is to create a clear path for fault current to return to the source. However, in a subpanel, grounds and neutrals must be kept separate. When you install a neutral-to-ground bond in a subpanel (often by failing to remove the factory-installed bonding screw), you create parallel paths for return current.

This introduces objectionable current over grounding conductors, energizing the metal frames of equipment, raceways, and enclosures that are supposed to be safe to touch. This not only creates a serious shock hazard but can also cause issues with sensitive electronics. Always verify that neutrals and equipment grounds are on separate, isolated bus bars in any panel downstream of the service disconnect to prevent these dangerous subpanel grounding violations.

2. Misunderstanding Separately Derived Systems

Generators and transformers are common examples of separately derived systems, and they have their own specific grounding and bonding rules that often cause confusion. A system is separately derived if it has no direct electrical connection to the primary source, which often happens when a transfer switch opens the neutral conductor. In these cases, the system must be grounded and bonded at the source.

A frequent error is failing to install a Main Bonding Jumper (or system bonding jumper) at the correct location, which is typically at the generator or transformer itself, or at the first disconnecting means. Another common mistake is connecting the neutral and ground at a downstream panel instead of at the source. This violates the principles of NEC Article 250 and can prevent an effective ground-fault current path from being established, rendering overcurrent devices useless in a fault. Always determine if your system is separately derived and apply the specific rules found in NEC 250.30.

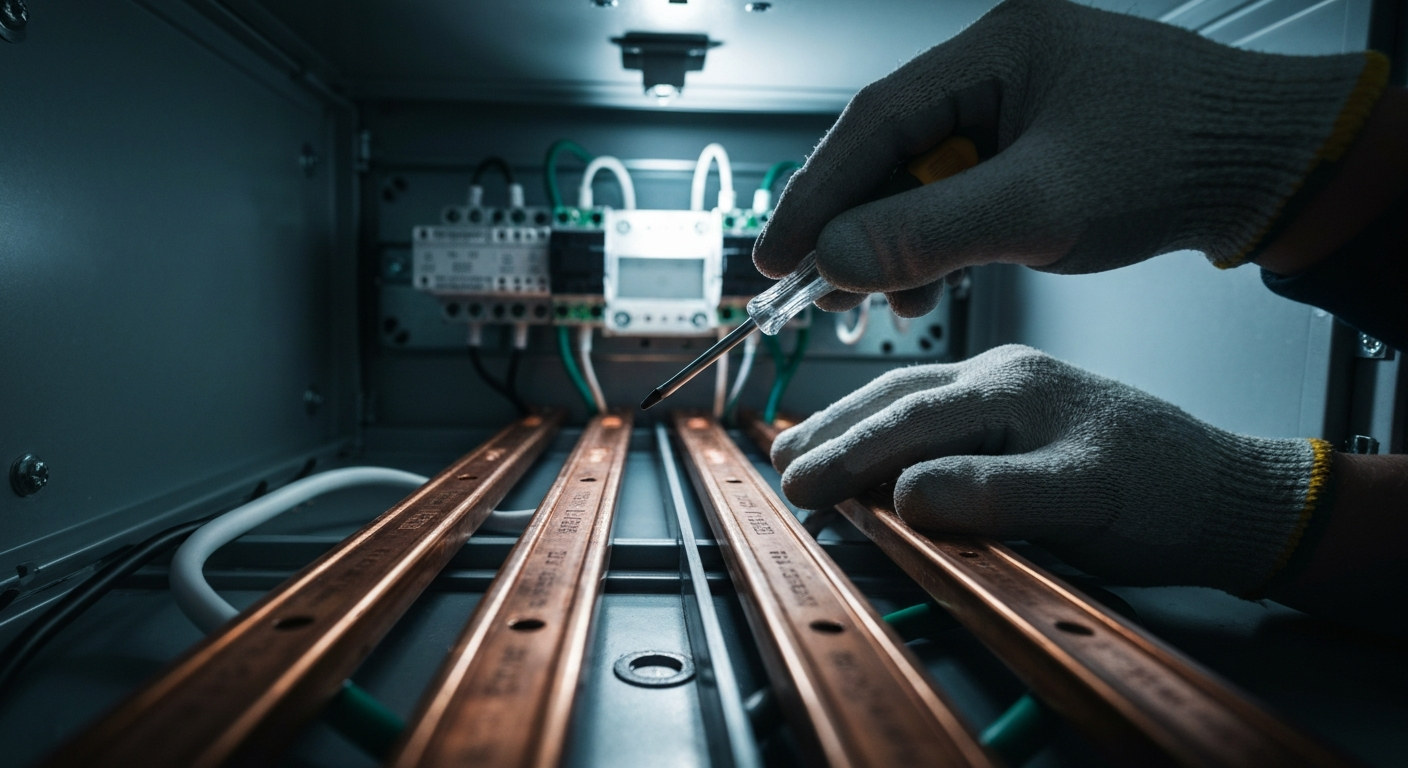

3. Incorrectly Sizing the Equipment Grounding Conductor (EGC)

The Equipment Grounding Conductor (EGC) is the hero that waits in the background. It doesn’t carry current in normal operation, but during a ground fault, its job is to carry enough current to trip the breaker or blow the fuse. To do this, it must provide a low-impedance path. A critical mistake is undersizing the EGC. Sizing for the EGC is determined by the rating of the overcurrent protection device, not the load, as outlined in NEC Table 250.122.

An undersized EGC can act like a resistor during a fault, limiting the current to a level that won’t trip the breaker. This leaves metal parts energized and creates a severe fire and shock hazard. It’s also important to remember that if you upsize your phase conductors for voltage drop, you must proportionally increase the size of your EGC. For more details on these rules, especially recent updates, it’s helpful to review changes to EGC sizing in the 2023 NEC.

4. Inadequate Grounding Electrode System Installation

The Grounding Electrode Conductor (GEC) connects the electrical system to the earth via the grounding electrode system. Common mistakes here often involve poor connections or a misunderstanding of what constitutes a valid electrode. Using unlisted clamps, failing to protect the conductor from physical damage, or not bonding all available electrodes together are frequent violations.

A classic error is installing a single ground rod and assuming it meets the 25-ohm resistance requirement without testing. Unless you can prove it with a test, NEC Article 250 requires a second ground rod to be installed. Furthermore, relying solely on a ground rod in areas with poor conductivity might not be enough. In these cases, a concrete-encased electrode (Ufer ground) is a far superior option. Proper installation is critical for dissipating lightning energy and managing step and touch potential during a fault. For difficult conditions, advanced methods like soil resistivity testing may be necessary to engineer an effective system.

5. Failure to Bond All Required Metallic Components

So, bonding what is it, exactly? Bonding is the act of connecting all non-current-carrying metallic components together to ensure they are at the same electrical potential. This creates a reliable and effective ground-fault current path to get fault current back to the source. A frequent mistake is overlooking metallic systems like water piping, gas piping (where required by the AHJ), and structural steel, and failing to bond them to the grounding electrode system.

It’s also common to see a metal raceway as grounding conductor used without ensuring all connections are tight and secure, compromising the path. It is vital to distinguish this system-level protection from device-level protection. A GFCI outlet or GFCI breaker is designed to protect people from shock by detecting small imbalances in current, while an arc fault breaker protects against arcing that can cause fires. These are excellent safety devices, but they are not a substitute for a properly bonded system that is designed to clear major faults. Even with GFCI and AFCI protection, a missing bond can leave dangerous potential between different metallic systems. Improving safety often involves a layered approach, including understanding how to handle non-grounding receptacles and other legacy wiring situations.

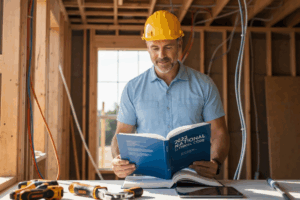

Conclusion: Mastery Through Diligence

Grounding and bonding are complex subjects, but avoiding these common mistakes boils down to a commitment to understanding the “why” behind the code. A properly installed system provides a stable, safe foundation that protects both people and property. By mastering the requirements of NEC Article 250 and paying close attention to these critical details on every job, you elevate your craftsmanship, ensure passing inspections, and reinforce your reputation as a true professional. Continuing education is key to staying sharp and understanding how the NEC evolves to improve worker safety.

Ready to sharpen your code knowledge and stay ahead of the curve? Browse our courses at ExpertCE to find state-approved continuing education that fits your schedule.

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)