Why NEC Panel Clearance Rules Are a Matter of Life and Death

For the qualified electrical worker, enforcing these rules isn’t about being difficult—it’s about ensuring you go home at the end of the day. Let’s break down why the NEC panel clearance rules are one of the most important safety standards in our industry.

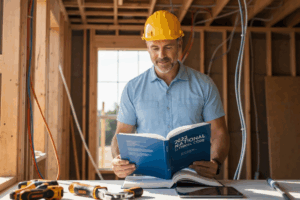

The Foundation of Safety: Understanding NEC 110.26

The cornerstone of panel clearance is NEC 110.26, “Spaces About Electrical Equipment.” This section of the National Electrical Code outlines the mandatory clearances required around equipment that may need examination, adjustment, servicing, or maintenance while energized. It defines two key areas: the electrical panel working space and the dedicated electrical space.

- Working Space (NEC 110.26(A)): This is the three-dimensional zone required for a worker to perform tasks safely. It must be at least 3 feet deep from the face of the panel, 30 inches wide (or the width of the equipment, if wider), and 6.5 feet high. This space must be kept clear at all times—no storage, no equipment, no excuses.

- Dedicated Electrical Space (NEC 110.26(E)): This is the space reserved from floor to 6 feet above the equipment (or to the structural ceiling, whichever is lower). This zone must remain free of foreign systems like plumbing, HVAC ducts, or architectural features to prevent leaks and allow for future conduit runs.

These rules ensure basic panelboard accessibility, giving electricians the physical room to work without being contorted or cramped, which is the first step in preventing contact with energized parts and ensuring proper equipment grounding checks can be performed.

Key 2023 NEC Updates That Enhance Worker Safety

The code is a living document, and recent changes to the NEC have further strengthened these protections, directly addressing real-world hazards. The 2023 NEC cycle introduced critical updates to Section 110.26 that every electrician should know.

One of the most significant changes concerns the egress path. Previously, the rule that open equipment doors must not impede egress was limited to large equipment. The 2023 NEC expanded this rule to apply to all electrical equipment. This is a direct response to the risk of a worker being trapped by an open panel door during an arc flash event. Understanding these evolving standards is crucial, especially when considering how 2023 NEC arc flash hazard warning requirements are different. This change ensures that a clear path of retreat is always maintained.

Another vital addition is Section 110.26(A)(6), which mandates that the floor in the working space must be kept clear and be “as level and flat as practical.” This simple line item directly reduces tripping hazards, providing stable footing for electricians who are often focused on the complex task at hand, not the clutter at their feet. These updates are a clear indicator of how the 2023 NEC improves electrical worker safety around equipment, focusing on practical, life-saving details.

OSHA, Arc Flash Boundaries, and the High Cost of Non-Compliance

Failure to maintain panel clearance isn’t just a code violation; it’s an electrical hazard that can have severe legal and financial consequences. OSHA 1910.303 directly references NEC standards for workplace electrical safety, making NEC compliance a legal requirement in the eyes of federal regulators. An obstructed panel is a common and easily identifiable violation, and fines can be steep—as of 2022, a serious violation could cost over $14,500, with willful or repeated violations exceeding $145,000.

Beyond fines, obstructed working space dramatically increases the risk during an arc flash event. A critical part of job safety planning involves understanding the arc flash boundary, the limited approach boundary, and the restricted approach boundary. When an electrician cannot maintain a safe distance because of clutter, they are forced to work deeper within these hazardous zones. A proper job safety plan, as outlined by evolving standards like NFPA 70E, is impossible without first establishing the clear working space required by the NEC. To stay current, it’s essential to know how NFPA 70E updates have changed electrical job safety planning.

From Routine Jobs to Critical Failures: Real-World Impact

Consider a few common scenarios for a residential electrician:

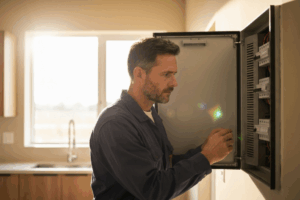

- Routine Maintenance: You’re called for a simple circuit breaker replacement. The homeowner has stacked storage bins in front of the panel. Now, a 15-minute job involves moving heavy boxes, wasting time, and creating a cramped, awkward workspace. You might struggle to use your circuit breaker finder effectively or have trouble maneuvering tools, increasing the chance of an accidental slip.

- Troubleshooting an Issue: A customer reports a nuisance-tripping GFCI breaker or arc fault breaker. This requires careful diagnosis. A cluttered space adds stress and physical obstacles, making it harder to focus on the technical problem and easier to make a mistake.

- The Worst-Case Scenario: While you’re working, a fault occurs, causing an arc flash. The path behind you is blocked. You can’t escape the blast of heat and pressure. This is where panel clearance becomes a life-or-death issue. The 36 inches of clear space is your lifeline, providing the bare minimum distance to react and retreat.

In every case, a clear working space transforms the job from hazardous and inefficient to professional and safe. It’s a non-negotiable part of any professional electrical equipment maintenance task.

Conclusion: Upholding the Standard

As licensed professionals, it’s our responsibility to not only follow the code but also to educate clients on why it matters. The next time you see a panel blocked by shelving, furniture, or storage, take the opportunity to explain the risks. Frame it not as an inconvenience, but as a critical safety measure for them, their property, and any professional who needs to work on their system. Upholding the NEC panel clearance standard protects the entire trade and ensures that every electrician has the safe environment they need to do their job properly and, most importantly, to return home safely. Continuing education is key to staying on top of these vital safety standards. Browse our courses to ensure your knowledge is current and your safety practices are sharp.

Frequently Asked Questions (FAQ)

- 1. Can I store items in the dedicated electrical space above or below the panel?

- No. The dedicated electrical space defined in NEC 110.26(E) must remain clear. This prevents issues like water damage from overhead pipes and reserves the space for future electrical installations and heat dissipation from the equipment.

- 2. Does the 3-foot clearance rule apply to residential panels too?

- Yes, absolutely. The rules in NEC 110.26 apply to dwelling units as well. A residential electrician faces the same arc flash and shock hazards as an industrial electrician, and requires the same safe electrical panel working space to perform tasks like a circuit breaker replacement or troubleshooting a faulty GFCI breaker.

- 3. What’s the main difference between “working space” and “dedicated space”?

- Think of it this way: “Working space” (NEC 110.26(A)) is the ‘keep clear’ zone in front of the panel where you stand and work. “Dedicated space” (NEC 110.26(E)) is the rectangular zone the panel sits within, extending from the floor to a height of 6 feet above the equipment or to the structural ceiling, whichever is lower. This space must be free of non-electrical systems.

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)