What is an Inverse Time Circuit Breaker? A Technical Primer

The Core Principle: Thermal-Magnetic Trip Mechanism

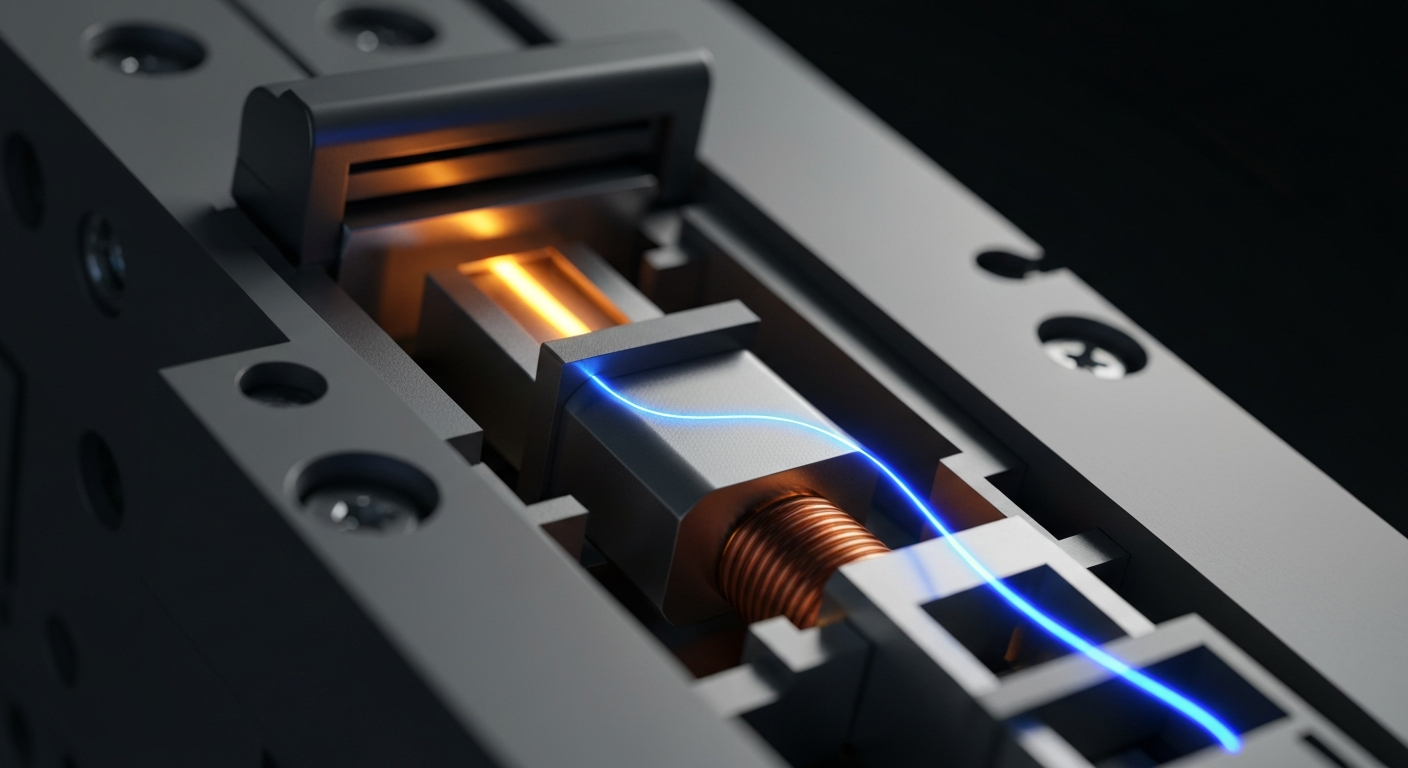

At the heart of nearly every standard inverse time circuit breaker is a sophisticated, two-part mechanism designed to distinguish between different types of overcurrent events. This thermal-magnetic trip system is the key to providing comprehensive protection without unnecessary interruptions. Understanding both components is essential for any professional electrician.

The “Inverse Time” Component: Thermal Overload Protection

The “inverse time” characteristic is managed by a thermal element, typically a bimetallic strip. This strip is composed of two different metals bonded together, each with a different rate of thermal expansion. When current flows through it, the strip heats up. During a sustained, low-level overcurrent—characteristic of an overload condition—the heat causes the strip to bend. If the overload persists long enough, the strip bends far enough to physically trip the breaker’s latch mechanism. The “inverse” relationship comes from the fact that a small overload (e.g., 125% of rating) will take a relatively long time delay to generate enough heat to trip, whereas a larger overload (e.g., 300%) will trip much faster. This intelligent delay prevents nuisance tripping from temporary inrush currents, such as the initial motor starting current.

The “Instantaneous” Component: Magnetic Short-Circuit Protection

While thermal protection is for overloads, magnetic protection is for short circuits. This part of the mechanism consists of an electromagnet (or solenoid). Under normal conditions, the magnetic field is negligible. However, during a short circuit or high-level ground fault, the current increases dramatically and instantaneously. This surge creates a powerful magnetic field that instantly pulls a plunger or armature to trip the breaker’s latch. This response is independent of heat and occurs in a matter of milliseconds. This rapid action provides critical short-circuit protection, interrupting the dangerous fault current before it can cause catastrophic damage to equipment or start a fire. A breaker’s ability to safely interrupt this high current is defined by its ampere interrupting capacity (AIC) or interrupting rating.

Decoding the Time-Current Curve (TCC)

The performance of an inverse time circuit breaker is graphically represented by its time-current curve (TCC). This graph is one of the most important tools for an engineer or electrician, plotting trip time on the y-axis against current on the x-axis. Mastering TCCs is crucial for correct breaker trip curve selection and achieving proper system coordination.

The curve clearly shows the two distinct regions of operation:

- The Overload Region: This is the upper, sloped portion of the curve, representing the “inverse time” thermal trip. You can see how a lower current results in a longer trip time.

- The Short-Circuit Region: This is the lower, vertical (or near-vertical) portion, representing the instantaneous magnetic trip. It shows that once current exceeds a certain threshold, the breaker trips almost instantly, regardless of a further increase in current.

A Step-by-Step Guide to Breaker Trip Curve Selection

Properly selecting a breaker involves more than just matching the amp rating to the conductor. It requires analyzing the TCC to ensure it aligns with the load’s characteristics and coordination requirements.

- Identify Load Characteristics: Determine the type of load being protected. Is it a motor with high inrush current, a transformer, or a resistive heating load?

- Calculate Currents: Determine the full load amperes (FLA) of the equipment and estimate the magnitude and duration of any inrush currents, such as motor starting current.

- Consult Manufacturer TCCs: Obtain the specific TCC charts from the breaker manufacturer for the models you are considering. Do not use generic curves.

- Overlay and Analyze: Plot the load’s inrush current and steady-state current on the TCC. On a standard TCC graph (time on the vertical axis, current on the horizontal), the breaker’s trip curve must be positioned to the right of and above the load’s inrush current characteristic to avoid nuisance trips, and to the left of and below the conductor’s damage curve to ensure protection.

- Verify Code Compliance: Ensure your selection meets all requirements outlined in NEC Article 240, Overcurrent Protection, and other relevant codes. Understanding how the 2023 NEC changes standard circuit breaker amp ratings is crucial for modern installations.

The Role of UL 489 and Circuit Breaker Coordination

For a circuit breaker to be used for branch-circuit protection in the United States, it must be tested and listed under UL 489, the “Standard for Molded-Case Circuit Breakers, Molded-Case Switches, and Circuit-Breaker Enclosures.” This standard ensures the device, often a molded case circuit breaker (MCCB), can perform safely under specified overload and short-circuit conditions.

Beyond individual breaker performance, a critical system-level goal is circuit breaker coordination, more formally known as selective coordination. This is the practice of selecting and setting OCPDs so that the device immediately upstream of a fault opens first, leaving the rest of the electrical system energized. Proper selective coordination is achieved by carefully analyzing the TCCs of all breakers in series, ensuring their curves do not overlap. The NEC has expanded these requirements over the years, and staying current on the new selective coordination requirements is vital, especially when dealing with critical systems. For instance, understanding selective coordination for emergency system OCPDs is now a mandatory part of ensuring life safety and system reliability.

Practical Applications and Special Considerations

While the thermal-magnetic principle is common, specific applications demand specialized breakers. As a field professional, you’ll encounter various types designed for unique loads.

HACR Breakers for HVAC Systems

Breakers intended for Heating, Air-Conditioning, and Refrigeration (HACR) applications are designed and tested to tolerate HVAC inrush characteristics. Modern breakers that meet the appropriate UL standards and are listed or classified for the intended application will perform safely on HVAC loads. Always confirm both the breaker listing and the panel’s approval for that breaker before assuming compatibility.

The Challenge of Bryant Breaker Replacement

A common field query involves Bryant breaker replacement. Bryant is a legacy panel brand still found in many installations. When replacing a faulty breaker in a Bryant or any legacy panel, you cannot use just any brand. You must use breakers specifically listed and classified by UL for use in that specific panel. This compatibility information is part of UL’s Classification program. You must verify compatibility using an authoritative source, such as the breaker’s manufacturer compatibility documentation. Using a non-classified breaker is a code violation and can create a serious fire hazard due to a poor connection to the busbar.

Feeling confident about these concepts? Take it a step further. Go beyond the basics with our advanced courses on overcurrent protection.

Key Takeaways for the Professional Electrician

- The inverse time function is for overload protection; the instantaneous function is for short-circuit protection.

- The time-current curve (TCC) is your primary tool for ensuring a breaker will perform correctly with its intended load and coordinate with other devices.

- Always use UL 489 listed breakers for branch circuit protection.

- Achieving selective coordination requires a detailed study of the TCCs for all series devices to ensure only the nearest upstream device trips.

- For a Bryant breaker replacement or any other legacy brand, you must use a breaker specifically classified as a compatible replacement to ensure a safe and code-compliant installation.

Primary Sources

Frequently Asked Questions (FAQ)

- How does an inverse time circuit breaker prevent nuisance tripping with motors?

- An inverse time circuit breaker uses its thermal trip element (a bimetallic strip) to create a time delay. This allows the breaker to “ride through” the temporary, high inrush current of a motor starting without tripping. The “inverse time” property ensures it will still trip on a sustained overload but ignores harmless, short-duration events, thus preventing nuisance tripping.

- What is the difference between overload protection and short-circuit protection in a thermal-magnetic trip breaker?

- In a thermal-magnetic trip breaker, overload protection is handled by the slow-acting thermal element that responds to prolonged, low-level overcurrents. Short-circuit protection is handled by the fast-acting magnetic element that responds instantly to dangerous, high-magnitude fault currents.

- Why is understanding the time-current curve (TCC) essential for selective coordination?

- Selective coordination requires that the breaker closest to a fault trip first. The time-current curve (TCC) for each breaker in a system must be analyzed to ensure there is no overlap. By properly spacing the curves of downstream and upstream breakers, you guarantee that a fault on a branch circuit will trip only the branch breaker, not the main or feeder breaker, thus maintaining power to the rest of the system.

- Can I use any modern breaker for a Bryant breaker replacement?

- No. For a safe and code-compliant Bryant breaker replacement, you must use a breaker that is specifically UL Classified and/or Listed for use in a Bryant panel. Check the panel labeling and the new breaker’s documentation to ensure compatibility.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)