What is a VFD? A Technical Guide to Variable Frequency Drives

The Core Concept: VFD Working Principle

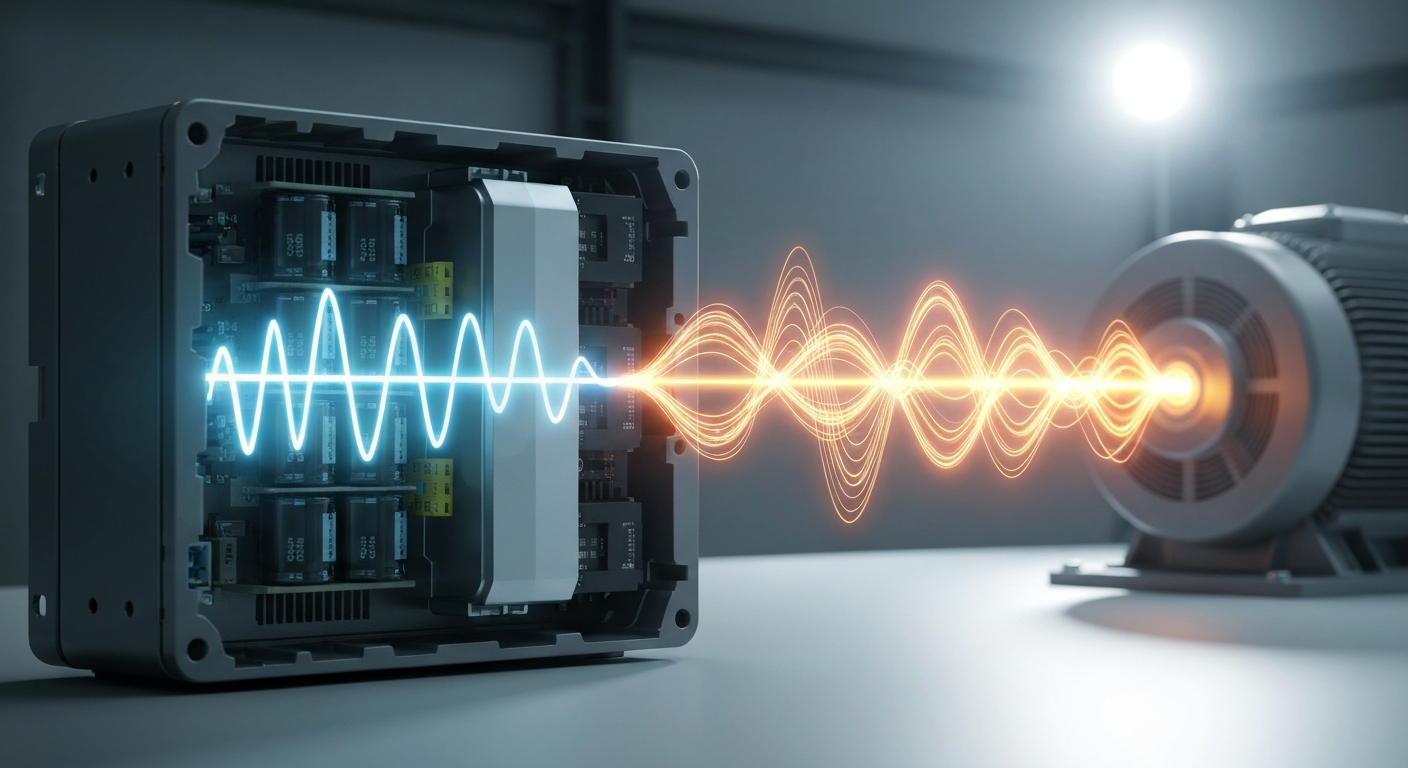

To truly understand what a VFD is, we must look at its internal process. The majority of AC induction motors in the field are designed to run at a specific, constant speed determined by the number of motor poles and the frequency of the AC power line (typically 60 Hz in the United States). A variable speed drive fundamentally changes this relationship by manipulating the power supplied to the motor. The VFD working principle can be broken down into three primary stages:

1. The Rectifier: AC to DC Conversion

The first stage of a vfd takes the incoming standard AC line voltage and converts it into DC voltage. This is accomplished using a full-wave diode bridge or a more complex SCR (Silicon Controlled Rectifier) configuration. The output of this stage is a raw DC voltage.

2. The DC Bus: Filtering and Smoothing the Power

The DC voltage from the rectifier is not smooth; it contains ripples. The DC bus, which consists of large capacitors, acts as a filter to smooth out these ripples and create a stable, clean DC voltage. This stored energy is crucial for the final stage of the process.

3. The Inverter: DC Back to Simulated AC

This is the most critical stage of the inverter drive. The inverter section uses high-speed transistors (typically Insulated Gate Bipolar Transistors, or IGBTs) to “chop up” the DC voltage and reconstruct a three-phase AC power waveform at the desired output frequency. The technique used to accomplish this is called Pulse Width Modulation (PWM). By rapidly switching the transistors on and off, the VFD can vary the width of the output pulses, effectively simulating a sine wave of any required frequency and voltage, giving it complete control over the motor’s speed.

Key Benefits: Why Use an Adjustable Speed Drive?

The primary reason for installing an adjustable speed drive is to achieve precise process control and energy efficiency. While a simple motor starter is cheap, a VFD offers a suite of benefits that provide a rapid return on investment.

- Energy Savings: This is the most significant advantage. For centrifugal loads like fans and pumps, the power required is proportional to the cube of the speed (Affinity Laws). Reducing a motor’s speed by just 20% can result in energy savings of nearly 50%.

- Precise Motor Speed Control: A VFD allows for smooth, stepless speed adjustment, enabling operators to perfectly match motor output to process demand.

- Reduced Mechanical Stress: The integrated soft-start and soft-stop capabilities ramp the motor’s speed up and down gradually, eliminating the mechanical shock and high inrush currents associated with across-the-line starting.

- Improved Power Factor: VFDs can improve motor-driven system performance, but the drive’s input power factor depends on front-end topology and load. Drives with an active front end (AFE) can achieve near-unity input power factor and reduced harmonics; simple diode-rectifier front ends present near-unity displacement but can have reduced overall power factor due to harmonic distortion unless line reactors or filters are applied.

Common Applications in the Field

VFDs are ubiquitous in modern facilities. A common and highly effective application is in commercial HVAC systems. In a VAV HVAC (Variable Air Volume) system, a VFD is used to control the speed of the main hvac blower motor. As the demand for conditioned air changes throughout the building—signaled by a line voltage thermostat or a more complex building automation system that may use a line voltage to thermostat relay power supply—the VFD modulates the fan speed. Instead of running the fan at full speed and using dampers to restrict airflow (a highly inefficient method), the VFD slows the fan down, saving a tremendous amount of energy. Similar principles apply to pumps, conveyors, extruders, and countless other machines that benefit from variable speed operation.

VFD Installation Wiring and Best Practices

Proper installation is paramount for reliable VFD performance. Rushing the VFD installation wiring process can lead to operational faults, equipment damage, and safety hazards. Follow these key steps:

- Sizing and Selection: Ensure the VFD is correctly sized for the motor’s full-load amperage (FLA) and voltage. This includes properly sizing the conductors and protection devices feeding the drive. For detailed guidance on this, it’s crucial to understand how the 2023 NEC simplifies motor conductor sizing and protection device selection.

- Enclosure and Environment: Select the correct NEMA rating for VFD enclosures based on the environment (e.g., NEMA 1 for clean, dry indoor locations; NEMA 4X for washdown or corrosive environments). In potentially hazardous locations, a full safety assessment is required. This involves understanding basic principles, such as why an enriched environment is dangerous (is oxygen flammable? No, but it’s an oxidizer that accelerates fire) and knowing the properties of materials on site (e.g., is diesel flammable? It is combustible and poses a risk).

- Power and Control Wiring: This is a critical step. Use shielded, VFD-rated cable for the connection between the drive and the motor to limit reflected waves and protect motor insulation. Run power and control wiring in separate conduits or maintain maximum practical separation to prevent interference. Proper grounding is also essential for safety and to mitigate noise; it’s the professional answer to how to get rid of static electricity that can damage sensitive electronics.

- NEC Compliance and Protection: Always adhere to the National Electrical Code. This includes rules regarding surge protection and industrial control wiring; the NEC includes updated guidance that affects industrial control panels and surge protection practice—consult the NEC and manufacturers for specifics and see how 2023 NEC rules on surge protection for industrial control panels impact installations for an explanatory overview. Also, be aware of rules that address reconditioned motors; see how reconditioned motors are addressed in the 2023 NEC.

VFD Programming and Troubleshooting

Once installed, basic VFD programming is required. This typically involves setting parameters like motor nameplate data (voltage, FLA, RPM), minimum/maximum speed, and acceleration/deceleration times. For more complex jobs, VFD troubleshooting is a valuable skill. Key issues include:

- Harmonics: The switching nature of an AC drive can create electrical “noise” or VFD harmonics back onto the power line. This can interfere with other sensitive equipment. Line reactors or harmonic filters can be installed to condition the power for a VFD and mitigate these effects.

- Faults: VFDs have built-in protective features that will trigger faults. Common faults include overcurrent, overvoltage, and overheating. Troubleshooting involves checking the load, motor, and incoming power supply.

- Environmental Issues: Control rooms housing VFDs are critical assets. They are often protected by advanced systems, including a high-sensitivity photoelectric smoke detector, to ensure early warning of any potential fire hazard. Proper VFD maintenance, including regular cleaning of heatsinks and checking connections, is vital for longevity.

Mastering VFDs is a crucial skill for the modern electrician, opening doors to more advanced and higher-paying work in industrial settings. Advance your career with training in motor controls and industrial automation.

Primary Sources & Further Reading

- NFPA 70, National Electrical Code (NEC)

- NEMA (National Electrical Manufacturers Association) Standards

- IEC (International Electrotechnical Commission) Standards

Frequently Asked Questions about VFDs

What is a VFD and how does it compare to a soft starter?

A VFD (Variable Frequency Drive) is a motor controller that controls both the speed and torque of an AC motor by varying the input frequency and voltage. The key difference in the soft starter vs VFD debate is that a soft starter is only used to ramp a motor up to full speed and then is typically bypassed. It cannot control the motor’s operating speed. A VFD, however, provides full-range speed control throughout the entire operation, in addition to soft-start capabilities.

What are the critical steps for proper VFD installation wiring?

Proper VFD installation wiring involves several critical steps: ensuring correct VFD and conductor sizing for the motor, selecting the proper NEMA-rated enclosure, using shielded VFD-rated cable between the drive and motor, separating power and control wiring to prevent noise, and ensuring a solid, low-impedance ground path. Adherence to all applicable NEC articles is mandatory for a safe and reliable installation.

How does a VFD enable three-phase motor control?

A VFD enables precise three-phase motor control by fundamentally altering the power supplied to it. It converts incoming fixed-frequency three-phase (or single-phase) AC power to DC, then uses an inverter with Pulse Width Modulation (PWM) to create a new, variable three-phase AC waveform. By controlling the frequency of this output waveform, the VFD directly controls the synchronous speed of the motor’s magnetic field, allowing for exact speed regulation.

Continuing Education by State

Select your state to view board-approved continuing education courses and requirements:

Disclaimer: The information provided in this educational content has been prepared with care to reflect current regulatory requirements for continuing education. However, licensing rules and regulations can vary by state and are subject to change. While we strive for accuracy, ExpertCE cannot guarantee that all details are complete or up to date at the time of reading. For the most current and authoritative information, always refer directly to your state’s official licensing board or regulatory agency.

NEC®, NFPA 70E®, NFPA 70®, and National Electrical Code® are registered trademarks of the National Fire Protection Association® (NFPA®)